Treatment method of xylose production wastewater

A technology for the production of waste water and treatment methods, which is applied in natural water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem that sewage cannot reach the second-level standard, which is not conducive to the construction of a beautiful China, and the treatment process Low removal rate and other problems, to achieve the effect of low maintenance cost, high oxygen utilization rate, and improve treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The processing method of embodiment 1 xylose production waste water

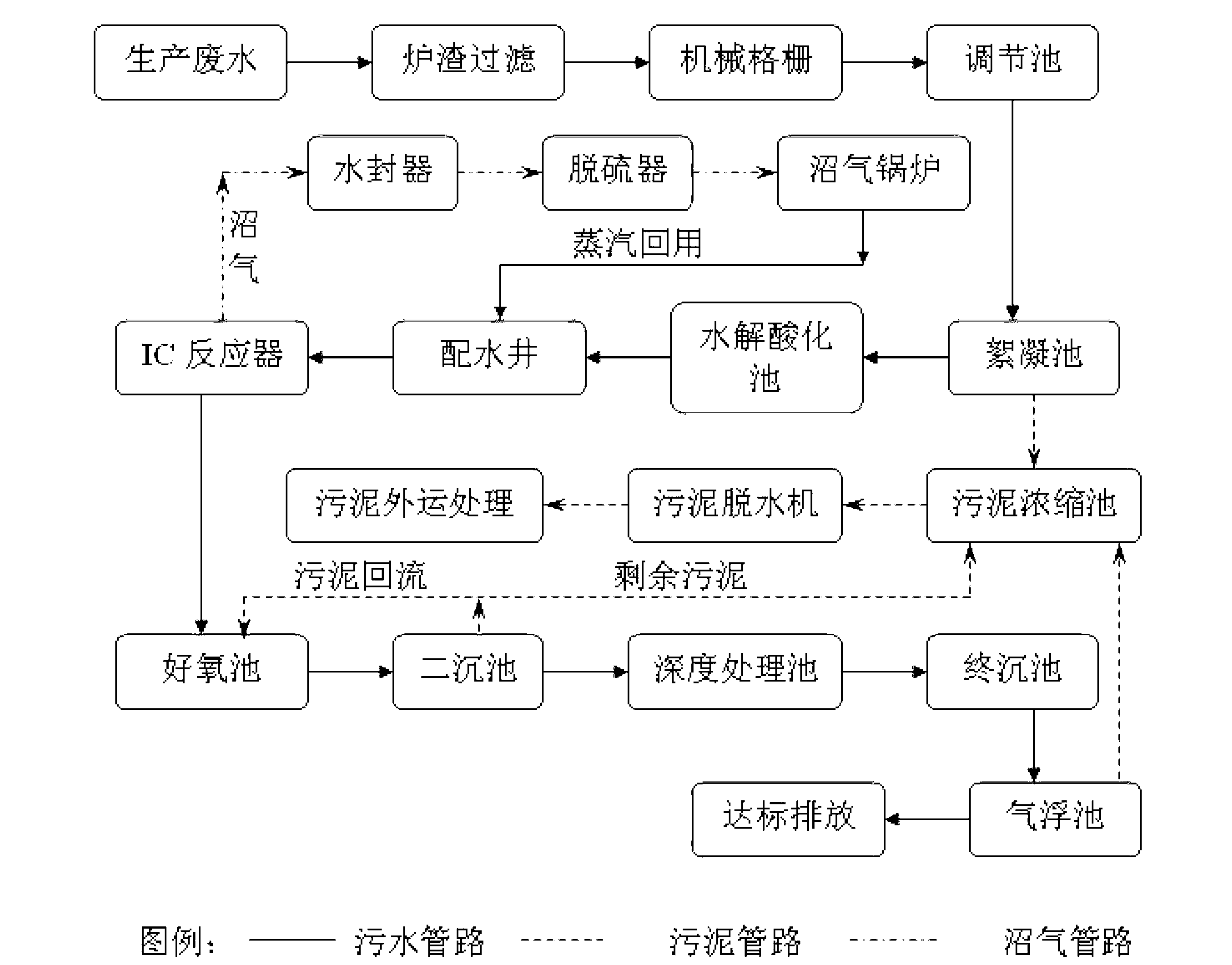

[0033] Flowchart such as figure 1 As shown, the steps are as follows:

[0034] (1) After being filtered and adsorbed by slag, the waste water from xylose production passes through the mechanical grid and enters the adjustment tank (fully mixes the COD and pH of the sewage to ensure stable water quality, and at the same time plays the role of buffer and temporary storage), and then enters the flocculation pool, add flocculant polyaluminum chloride and polyacrylamide to the flocculation pool, stir evenly through the flow of water, the suspended solids in the xylose production wastewater will be flocculated and precipitated, and enter the sludge concentration pool through the sludge discharge pipe, and go up The clear liquid enters the hydrolytic acidification tank;

[0035] (2) There is flocculent activated sludge at the bottom of the hydrolytic acidification tank. After the supernatant enters the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com