Backwash combination type farmland non-point source pollution cut-off purification system

A purification system, non-point source pollution technology, applied in climate change adaptation, chemical instruments and methods, water/sewage multi-stage treatment, etc., to save materials and construction costs, prolong hydraulic retention time, and maintain long-term high-efficiency maintenance of filler filtering and interception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

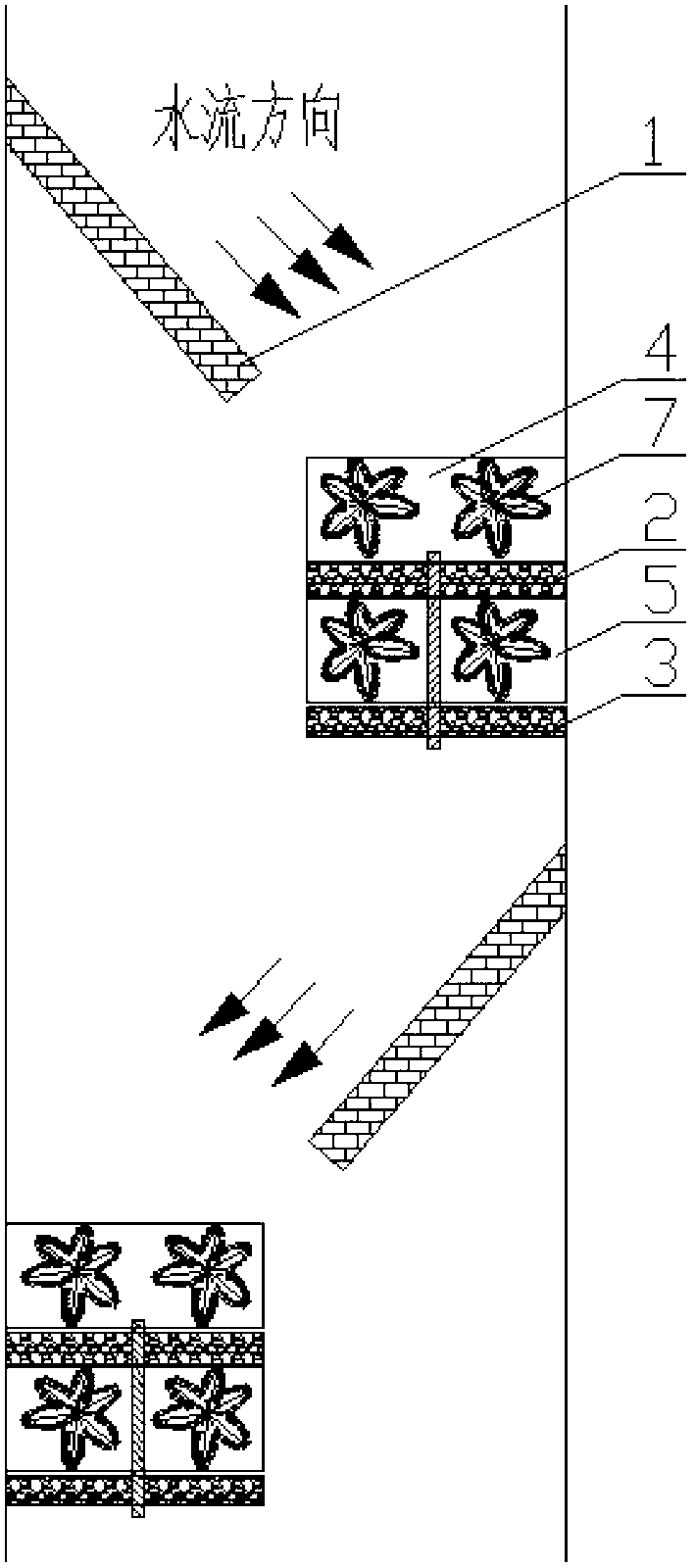

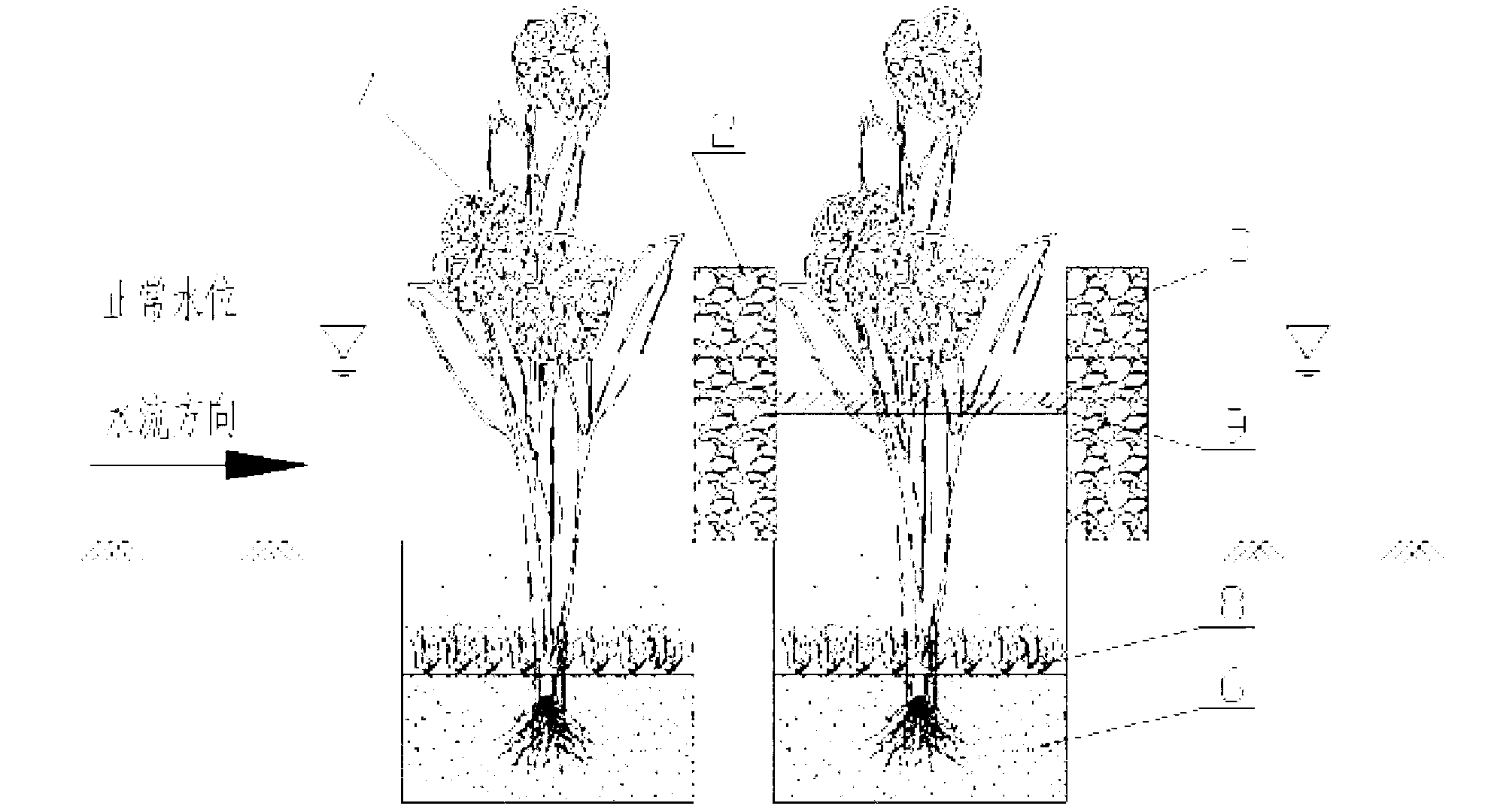

[0021] figure 1 It is a schematic plan view of the backwashing combined farmland non-point source pollution interception and purification system. It can be seen from the figure that there is a diversion overflow weir (1) at an angle of 40° to 60° along the canal wall or downstream of the embankment. The length of the overall vertical projection of the overflow weir (1) is 1 / 3-1 / 2 of the width of the channel or river, and the thickness is 30-50cm; A first-level ecological settlement pit (4) is set on the opposite bank with a vertical distance of 40-60 cm in the direction, and a second-level ecological settlement pit (5) is set downstream of the first-level ecological settlement pit (4). The structure and geometric dimensions of the pit (5) are the same as those of the first-level ecological settlement pit (4); there is a backwashable vertical filler A (2) between the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com