Industrial dyeing sewage treatment agent and preparation method thereof

A printing and dyeing sewage and treatment agent technology, applied in the direction of adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of secondary pollution, treatment effect needs to be improved, and high treatment cost, so as to achieve no secondary pollution, Ease of production and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

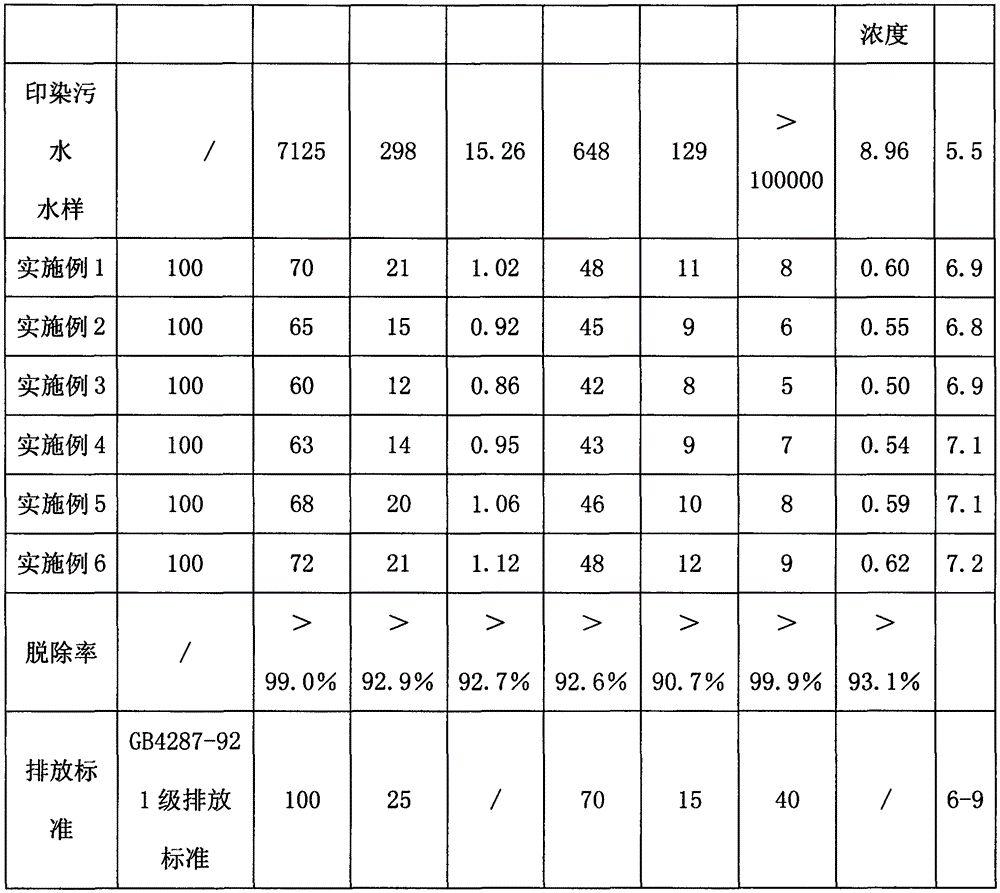

Examples

Embodiment 1

[0013] Industrial printing and dyeing sewage treatment agent, prepared from the following raw materials in weight percentage: polyaluminum chloride 25%, lime 10%, corn starch 18%, kaolinite 10%, graphene 6%, palygorskite 12%, silicon Alginate 16%, potassium permanganate 0.8%, bleaching powder 2.2%.

Embodiment 2

[0015] Industrial printing and dyeing sewage treatment agent, prepared from the following raw materials in weight percentage: polyaluminum chloride 28%, lime 12%, corn starch 12%, kaolinite 11%, graphene 6%, palygorskite 12%, silicon Alginate 16%, potassium permanganate 0.9%, bleaching powder 2.1%.

Embodiment 3

[0017] Industrial printing and dyeing sewage treatment agent, prepared from the following raw materials in weight percentage: polyaluminum chloride 30%, lime 11%, corn starch 15%, kaolinite 10%, graphene 5%, palygorskite 11%, silicon 15% algae earth, 1% potassium permanganate, 2% bleaching powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com