Low-foam organic waste gas absorbent, and preparation method and application thereof

An organic waste gas and absorbent technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as VOCs removal that affects mass transfer efficiency, affects pump operation and production safety, and foam occupies space in absorption towers, etc. , to achieve the effect of strengthening absorption and solubilization, improving mass transfer effect, and increasing gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The organic waste gas from a synthetic leather production, the concentration of main volatile organic compounds is: toluene 200~500mg / m 3 , Butanone 200~400mg / m 3 , Xylene 100~200mg / m 3 , the air volume is 3000~5000m 3 / h, temperature: 30-60°C.

[0035] The average emission concentration of untreated organic waste gas is: toluene 176.5mg / m 3 , Butanone 238.2mg / m 3 , Xylene 121.2mg / m 3. The composition of low-foaming organic waste gas absorbent and the concentration of organic waste gas before purification are shown in Table 1. The quality of VOCs absorbed and purified can reach 1 to 20 times the amount of surfactant used.

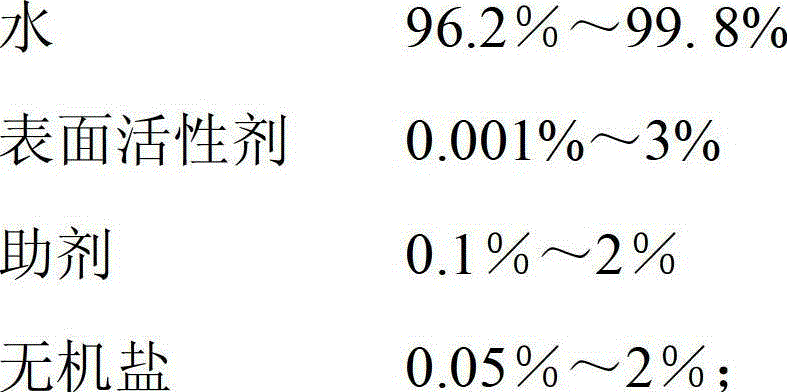

[0036] Low-foaming organic waste gas absorbent composition and purification effect in Table 1 Example 1

[0037]

Embodiment 2

[0039] The organic waste gas discharged from a petrochemical plant has a concentration of main volatile organic compounds: benzene 50-150mg / m 3 , Toluene 100~250mg / m 3 , Xylene 50~150mg / m 3 , Chlorobenzene 10~150mg / m 3 , the air volume is 3000~5000m 3 / h, temperature: 20-50°C.

[0040] The average emission concentration of untreated organic waste gas is: benzene 123.1mg / m 3 , toluene 116.1mg / m 3 , Xylene 167.2mg / m 3 , Chlorobenzene 72.6mg / m 3 . The composition of the low-foaming organic waste gas absorbent and the concentration of the purified organic waste gas are shown in Table 2. The quality of VOCs absorbed and purified can reach 1 to 20 times the amount of surfactant used.

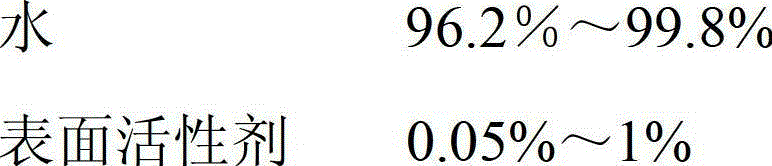

[0041] Low-foaming organic waste gas absorbent composition and purification effect in Table 2 Example 2

[0042]

Embodiment 3

[0044] The organic waste gas emitted by a semiconductor production, the concentration of main volatile organic compounds is: acetone 50-200mg / m 3 , methyl ethyl ketone 50~200mg / m 3 , Toluene 100~200mg / m 3 , the air volume is 3000~3000m 3 / h, temperature: 20-40°C.

[0045] The average emission concentration of untreated organic waste gas is: acetone 113.2mg / m 3 , methyl ethyl ketone 126.1mg / m 3 , toluene 126.2mg / m 3 . The composition of the low-foaming organic waste gas absorbent and the concentration of the purified organic waste gas are shown in Table 3. The quality of VOCs absorbed and purified can reach 1 to 20 times the amount of surfactant used.

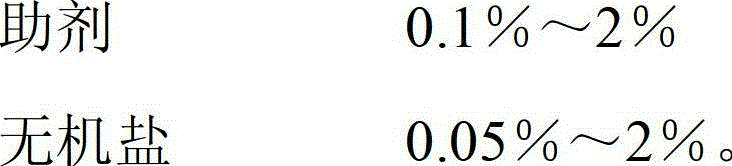

[0046] Low-foaming organic waste gas absorbent composition and purification effect in Table 3 Example 3

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com