Emulsifying defoaming system and PVB (Polyvinyl Butyral) resin production method employing the same

A production method and system technology, applied in the direction of foam dispersion/prevention, film/sheet adhesive, adhesive, etc., can solve problems such as laminated glass defects, and achieve easy phase change reaction, less foam, and better adhesion and the effect of optical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

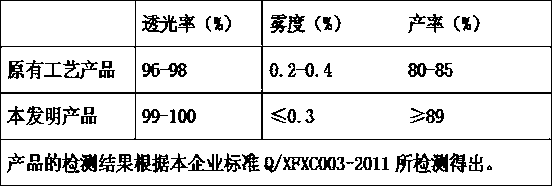

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of a solution containing an emulsified defoaming system: Dissolve 1.8kg of cetyl sodium sulfosuccinate (DOS) and 0.2kg of Tween 80 in 4L of ethanol, stir and mix evenly at 50°C, cool to room temperature, spare. At this time, the weight percentage of sodium cetyl sulfosuccinate in the emulsified defoaming system was 90%.

[0025] Dissolution of PVA: Add 8L of hydrochloric acid and 1kg of the above-mentioned solution containing the emulsified defoaming system to 1 ton of PVA aqueous solution with a weight concentration of 9% of PVA, mix and stir evenly. At this time, the weight ratio of PVB, hydrochloric acid and emulsified defoaming system is 100:8.3:0.32.

[0026] Condensation reaction with butyraldehyde: lower the temperature of the above mixed solution to 10° C., and add 50 kg of butyraldehyde within 30 minutes under stirring. After the addition of butyraldehyde was complete, the reaction temperature was raised to 13° C. and kept at this temperature for ...

Embodiment 2

[0030] Add 80L of hydrochloric acid, 0.23kg of sodium cetyl sulfosuccinate and 0.025kg of Tween 80 to 1 ton of 9% PVA aqueous solution and stir to mix evenly. That is: without preparing the solution of the emulsified defoaming system in advance, directly add sodium cetyl sulfosuccinate and Tween 80 to the reaction solution. All the other step processes are identical with implementation example 1.

Embodiment 3

[0032] The weight ratio of sodium cetyl sulfonate to Tween 80 in the emulsified defoaming system is 8:2.

[0033] Dissolution of PVA: Dissolve PVA into a PVA aqueous solution with a PVA weight concentration of 8%, add hydrochloric acid with a concentration greater than 30% and a solution containing an emulsified defoaming system into the PVA aqueous solution and stir evenly, so that the PVA, hydrochloric acid and emulsified defoaming system The weight ratio is 100:5:0.1.

[0034]Condensation reaction with butyraldehyde: lower the temperature of the PVA aqueous solution to 5°C; slowly add the butyraldehyde solution to the reaction solution within 30 minutes under stirring conditions, and the amount of butyraldehyde added is 45% of the weight of PVA; butyraldehyde After the dropwise addition, keep the temperature for 10 minutes, then slowly raise the temperature to 60° C. within 1 hour, and keep this temperature for 20 minutes.

[0035] Add alkali to neutralize: add alkali to n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com