Salty sauce containing meat particles for bread with long shelf life and preparation method thereof

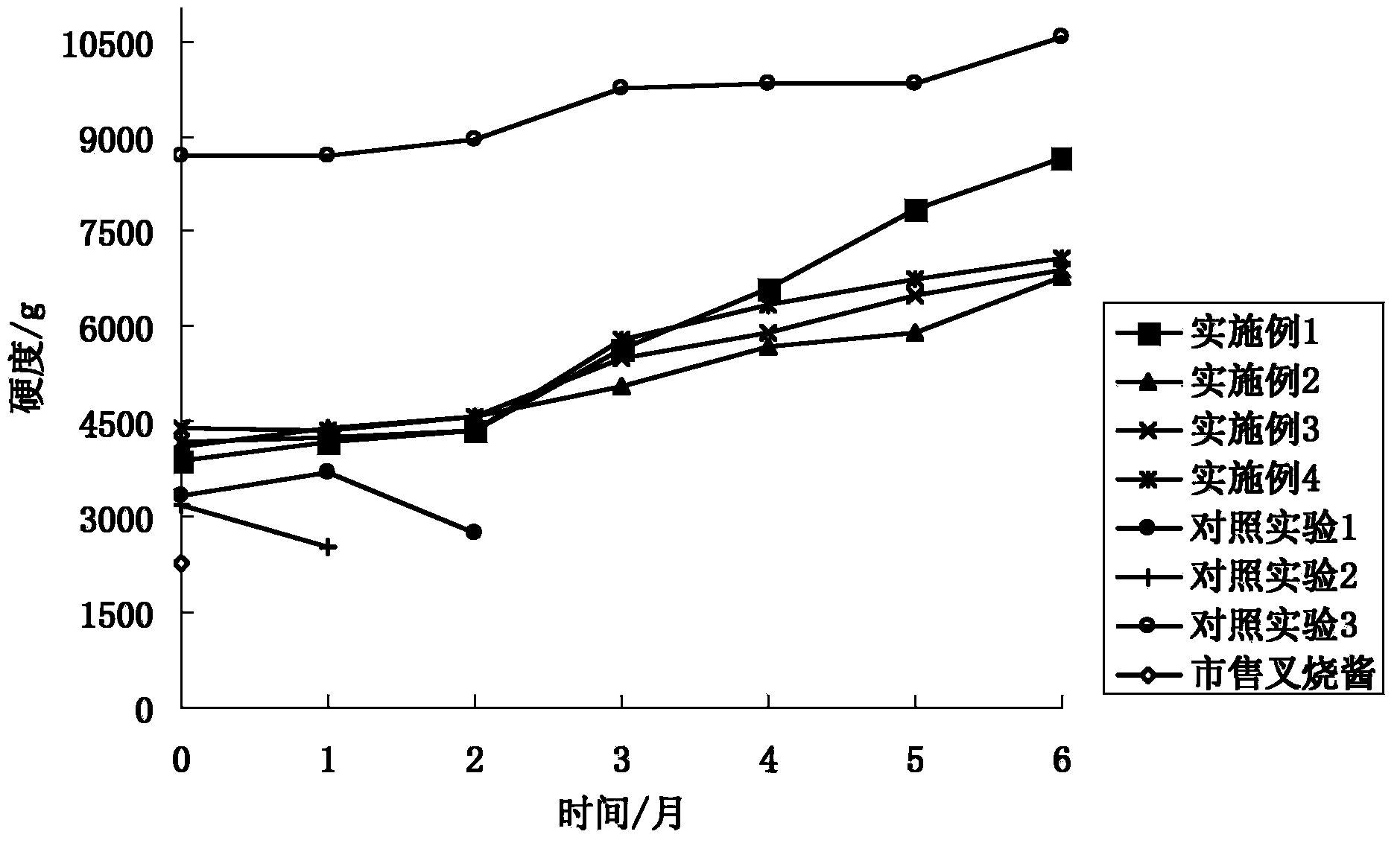

A technology of shelf life and salty sauce, which is applied in the field of meat-containing salty sauce and its preparation for bread with long shelf life, can solve the problems of high water activity, water loss of salty sauce, and increased moisture content of bread embryo, etc., to achieve enhanced Water-locking performance, low water activity, high moisture content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

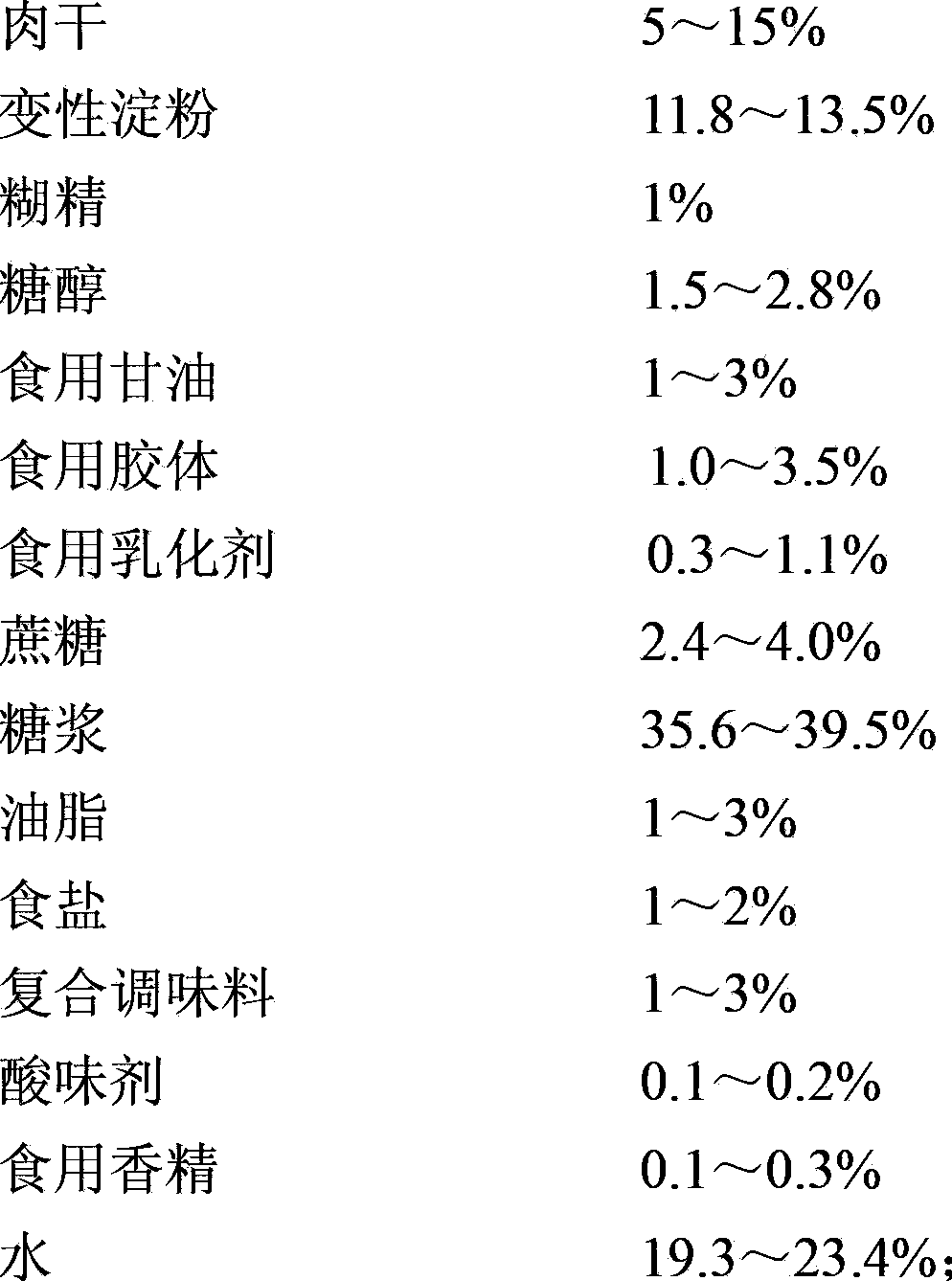

[0043] (1) Mix 27kg hydroxypropyl distarch phosphate, 2kg maltodextrin (food grade DE value 12), 5.6kg maltitol, 2kg gellan gum, 0.6kg molecularly distilled monoglyceride and 0.2kg potassium sorbate , through a 20-mesh sieve, put into a sandwich pot, and stir evenly with 6kg of refined white granulated sugar.

[0044] (2) Pour 48.8kg of water into the jacketed pot, stir until there are no visible particles, process it with a colloid mill until uniform, pour 79kg of maltose syrup (solid content is 85% by mass), 6kg of yellow cream, and 4kg of edible glycerin , 10kg pork jerky (diameter 0.3cm, moisture content 8%) and 6kg Huixiangyuan pork paste, turn on the steam, heat up to 90-95°C, and keep warm for 15 minutes until the gelatinization is complete. After the gelatinization is complete, add 2kg of salt, continue to stir and keep warm for 5 minutes, and control the solid content to 62-65%.

[0045] (3) Turn on the cooling water, lower the temperature to 70°C, put 0.2kg of citri...

Embodiment 2

[0047](1) Mix 25kg acetylated distarch phosphate, 2kg maltodextrin, 3.6kg sorbitol, 3.6kg guar gum, 2kg xanthan gum, 0.3kg calcium stearoyl lactylate, 0.7kg sodium stearoyl lactylate and 0.2kg of sodium dehydroacetate was mixed, passed through a 20-mesh sieve, put into a sandwich pot, and stirred evenly with 7kg of refined white granulated sugar.

[0048] (2) Pour 47.2kg of water into the jacketed pot, stir until there are no visible particles, process it with a colloid mill until uniform, pour 74kg of glucose syrup (solid content is 85% by mass), 4kg of yellow butter, and 3kg of edible glycerin , 20kg beef jerky (diameter 0.3cm, moisture content 9%) and 4kg Huixiangyuan beef extract, turn on the steam, heat up to 90-95°C, and keep warm for 15 minutes until the gelatinization is complete. At this time, it is semi-solid and the sauce is clear After the gelatinization is complete, add 2.6kg of salt, continue to stir and keep warm for 5 minutes, and control the solid content to 6...

Embodiment 3

[0051] (1) Mix 23.6kg hydroxypropyl distarch phosphate, 2kg maltodextrin, 4kg xylitol, 7kg xanthan gum, 1.6kg Haisheng modified soybean lecithin and 0.2kg potassium sorbate, pass through a 20-mesh sieve, Throw it into a jacketed pot and stir evenly with 4.8kg of refined white granulated sugar.

[0052] (2) Pour 43.4kg of water into the jacketed pot, stir evenly until there are no visible particles, and use a colloid mill to process until uniform, pour 71.2kg of maltose syrup (solid content is 85% by mass), 2kg of anhydrous butter, 2kg Edible glycerin, 30kg pork jerky (diameter 0.3cm, water content 8%) and 4kg Huixiangyuan pork paste, turn on the steam, heat up to 90-95°C, keep warm for 15 minutes, gelatinization is complete, at this time it is semi-solid, sauce After the gelatinization is complete, add 3.6kg of salt, continue to stir and keep warm for 5 minutes, and control the solid content to 62-65%.

[0053] (3) Turn on the cooling water, lower the temperature to about 70°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com