Culture medium and method for producing chitinase by Lecanicillium

A technology of chitinase and culture medium, which is applied in the field of culture medium for the production of chitinase by the fermentation of the lecanococcus fungus. The effect of high yield, short fermentation cycle and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

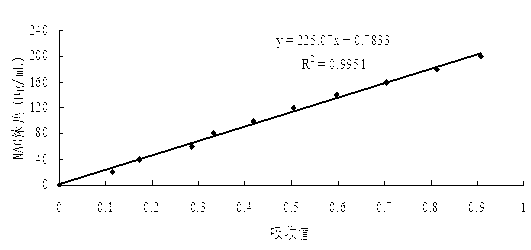

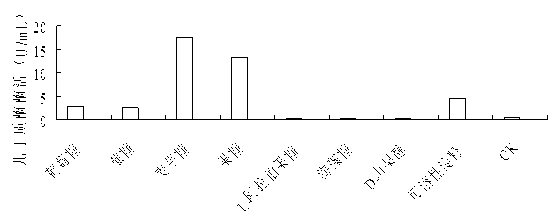

[0019] Single factor experiment to determine the optimal composition of culture medium

[0020] Implementation steps:

[0021] (1) Preparation of seed culture and basal medium: 1L of 20% potato juice (boiled from potato slices), 20g of glucose, natural pH. Packed in 250mL Erlenmeyer flask, each Erlenmeyer flask contains 150mL. 1.01MPa, sterilize for 20min. Antibiotics can be added to pre-treat the medium before use. Basal medium (liquid induction medium): powdered chitin 2%, KH 2 PO 4 0.1%, MgSO 4 。 7H 2 O 0.05%, NaCl 0.02%, pH6.5.

[0022] (2) Production of fermented seeds: Inoculate Lecanococcus sp. FJ28 on potato agar medium, culture at 26°C for 5 days, and activate after it produces spores; inoculate the activated strains with spore powder to the seeds with an inoculation needle The culture medium was cultured at 26°C for 4 days at a rotational speed of 160 r / min, which was the fermentation broth.

[0023] (3) Preparation of enzyme liquid: take the fermentat...

Embodiment 2

[0038] Orthogonal experiment to determine optimal fermentation conditions

[0039] (1) Orthogonal experiment to determine the best medium

[0040]On the basis of the culture medium determined by the single-factor experiment, various components and pH values were changed to configure different culture medium, and the method was the same as steps (1) and (2) in Example 1. See Table 1. Inoculate 250mL of the same amount of inoculum (10%) into 250mL of culture solution, and culture at 26°C with a rotation speed of 160 r / min for 4 days. Then measure the enzyme activity according to the steps (3) and (4) of Example 1. Select the experimental group number with the optimal result of the orthogonal experiment and the highest enzyme production, and carry out the verification experiment. In order to avoid being cumbersome, the preparation of the culture medium, the preparation of the crude enzyme solution, and the enzyme activity assay method in the embodiment are all the same as...

Embodiment 3

[0057] Fermentation method of Chitinase produced by Lecanococcus cerevisiae FJ28

[0058] (1) Preparation of fermented seeds

[0059] (A) Strain and culture medium

[0060] Bacteria: Lexococcus FJ28

[0061] Slant medium: PDA medium

[0062] Liquid seed medium: 1L of 20% potato juice, 20g of glucose, natural pH, 1.01MPa, sterilized for 20min.

[0063] (B) Preparation of seed solution

[0064] Transfer the pure species of Lecanococcus spp. FJ28 on the slant to several 250mL Erlenmeyer flasks filled with 100mL of culture medium, and then culture them at 26°C for 11d at the speed of 160 r / min on a reciprocating shaker until the hyphae grow. Robust, when the bacterial liquid is viscous, it means that the seeds have grown well.

[0065] (2) Fermentation culture

[0066] Fermentation medium: optimize the results of orthogonal experiments according to the medium, that is, 1% (w / v) maltose, 1% (w / v) yeast extract, 4×10 -4 mol / L Ca 2+ , 0.01%V B6 , pH 5.5, prepared. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com