Waterborne fluorine silicone resin modified acrylic acid concrete protective coating

A technology for water-based fluorosilicon and protective coatings, applied in the field of coatings, can solve the problems of poor water resistance, uneven emulsion performance, and unfavorable long-term effective protection of concrete, and achieve the effect of excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

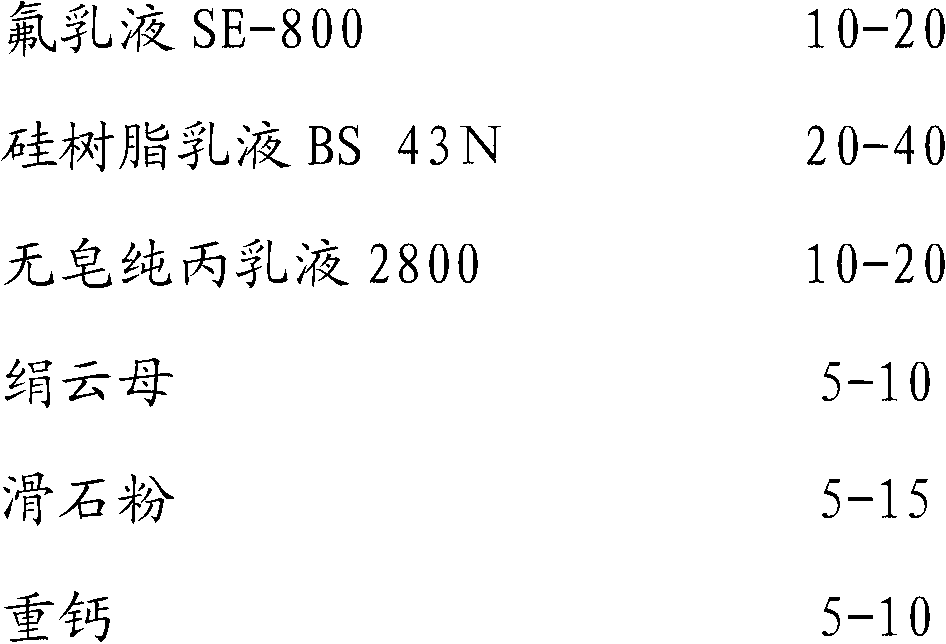

[0010] A water-based fluorosilicone resin modified acrylic concrete protective coating, comprising the following components, by weight, (g) fluorine emulsion SE-80010g, silicone resin emulsion BS 43N 20g, soap-free pure acrylic emulsion 280010g, sericite 10g, talcum powder 15g, heavy calcium 10g, dispersant OROTAN 7311.0g, PH regulator BS 160.2g, defoamer A-100.3g, antifreeze agent propylene glycol 1.0g, antifungal agent ZOE-2X 0.5g, thickener AP-101.0g , Film-forming aid 2.5g, hydrophobic agent BS1306 1.0g, leveling agent RM-20200.3g, tank fungicide MV 0.1g, deionized water 45g.

[0011] The preparation method of the above-mentioned fluorosilicone resin modified acrylic concrete protective coating is carried out according to the following steps:

[0012] ①Add deionized water, dispersant, PH regulator, defoamer, and antifreeze into the batching tank according to the proportion of parts by weight, stir at a low speed of 200-400 rpm for 5 minutes, then add sericite, talc powder,...

Embodiment 2

[0016] A water-based fluorosilicone resin modified acrylic concrete protective coating, comprising the following components, by weight, (g) fluorine emulsion SE-800 20g, silicone resin emulsion BS 43N 40g, soap-free pure acrylic emulsion 280020g, sericite 5g, talcum powder 5g, heavy calcium 5g, dispersant 740W 0.5g, PH regulator BS160.05g, defoamer NXZ, 0.5g, antifreeze agent propylene glycol 2.5g, antifungal agent ZOE-2X2g, thickener TT-9350.5g, Membrane aid 1.0g, hydrophobic agent BS13065.0g, leveling agent UH-4200.5g, tank fungicide MV 0.3g, deionized water 30g. The preparation method of the above-mentioned fluorosilicone resin modified acrylic concrete protective coating is carried out according to the steps in Example 1.

Embodiment 3

[0018] A water-based fluorosilicone resin modified acrylic concrete protective coating, comprising the following components, by weight, (g) fluorine emulsion SE-80015g, silicone resin emulsion BS 43N 30g, soap-free pure acrylic emulsion 280015g, sericite 8g, talcum powder 10g, heavy calcium 6g, dispersant OROTAN 11240.8g, PH regulator BS160.1g, defoamer F1110.4g, antifreeze agent propylene glycol 2.0g, antifungal agent ZOE-2X 1g, thickener ASE-600.6g, Membrane aid 1.5g, hydrophobic agent BS1306 3.0g, leveling agent UH-4200.4g, tank fungicide MV 0.2g, deionized water 40g.

[0019] The preparation method of the above-mentioned fluorosilicone resin modified acrylic concrete protective coating is carried out according to the steps in Example 1.

[0020] Specific instructions:

[0021] ① Waterborne fluorosilicone resin modified acrylic concrete protective coating uses three silicone products: silicone resin emulsion BS43N, pH regulator BS 16 and hydrophobic agent BS1306.

[0022]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com