Environment-friendly wear-resistant low-ice-adhesion anti-icing paint and preparation method and application thereof

An anti-icing and coating technology, applied in the direction of epoxy resin coating, polyester coating, polyether coating, etc., can solve the problem of hydrophobic materials losing anti-icing and frosting, and achieve easy removal, prolong service life and simple construction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

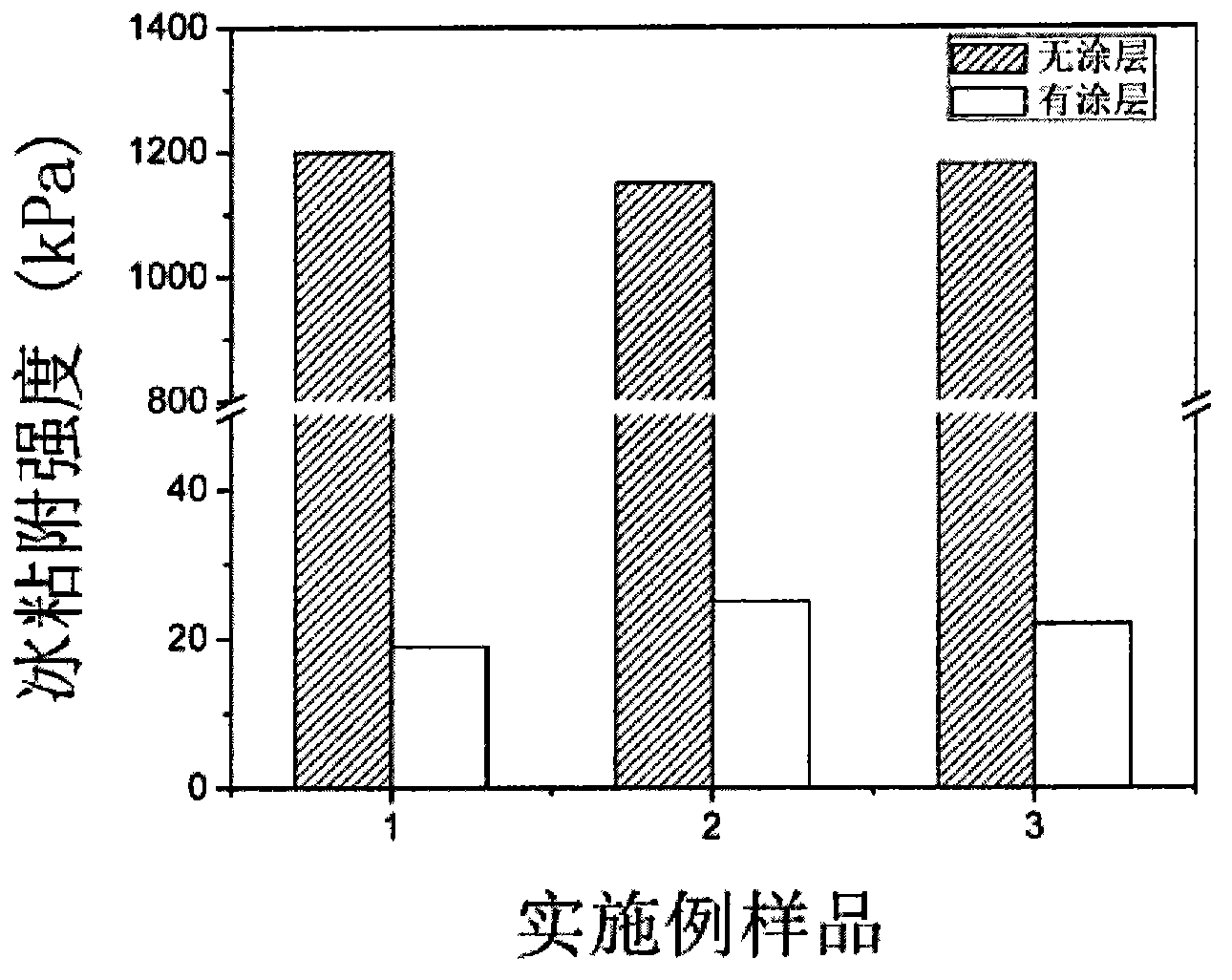

Embodiment 1

[0047] (1) Mix and stir the clay accounting for 5wt% of the mass of the water-based polyurethane with the water-based polyurethane to obtain the anti-icing coating component A.

[0048] (2) Add Bayhydur 3100 curing agent accounting for 10 wt% of water-based polyurethane to component A, and stir evenly to obtain the anti-icing coating.

[0049] (3) The anti-icing coating prepared in step (2) is directly coated on the surface of stainless steel and dried to form a film. After being dried and formed into a film, it is placed in an oven with a temperature of 90°C and heat-cured for 5 hours to obtain an anti-icing coating. Grinding, anti-icing coating with low ice adhesion strength.

[0050] When the ambient temperature is 0°C to -40°C and the ambient humidity is 1% to 99%, when the surface of the base material is frozen, the hydrophilic group contained in the anti-icing coating water-based resin prepared by the above method will absorb water. A non-freezing water film is formed o...

Embodiment 2

[0052] (1) Mix and stir the carbon nanotubes accounting for 2 wt% of the water-based epoxy resin and the water-based epoxy resin evenly to obtain the anti-icing coating component A.

[0053] (2) Add YW-50 curing agent accounting for 20 wt% of the water-based epoxy resin to component A, and stir evenly to obtain the anti-icing coating.

[0054] (3) The anti-icing coating prepared in step (2) is directly coated on the surface of carbon steel and dried to form a film. After being dried and formed into a film, it is put into an oven with a temperature of 120° C. for 6 hours for thermal curing to obtain a Abrasion resistant, anti-icing coating with low ice adhesion strength.

[0055] When the ambient temperature is 0°C to -40°C and the ambient humidity is 1% to 99%, when the surface of the base material is frozen, the hydrophilic group contained in the anti-icing coating water-based resin prepared by the above method will absorb water. A non-freezing water film is formed on the su...

Embodiment 3

[0057] (1) Mix aluminum oxide and water-based acrylate in an amount of 10wt% by weight of the water-based acrylate and stir evenly to obtain the anti-icing coating component A.

[0058] (2) Add an aziridine crosslinking agent (XR-100) accounting for 12 wt% of the water-based acrylate mass to component A, and stir evenly to obtain the anti-icing coating.

[0059] (3) The anti-icing coating prepared in step (2) is directly coated on the surface of red copper and dried to form a film. After being dried and formed into a film, it is placed in an oven with a temperature of 80° C. for 8 hours for thermal curing, and the anti-icing coating with anti-icing properties can be obtained. Grinding, anti-icing coating with low ice adhesion strength.

[0060] When the ambient temperature is 0°C to -40°C and the ambient humidity is 1% to 99%, when the surface of the base material is frozen, the hydrophilic group contained in the anti-icing coating water-based resin prepared by the above metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ice adhesion strength | aaaaa | aaaaa |

| Ice adhesion strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com