Production method of high-inflaming-retarding low-smoke halogen-free cable material

A production method and high flame-retardant technology, which is applied in the field of cable production and low-smoke halogen-free cable material production, can solve the problems of unspecified industrial production steps and failure to meet national standards, so as to be suitable for large-scale production and improve the phase interface , high filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

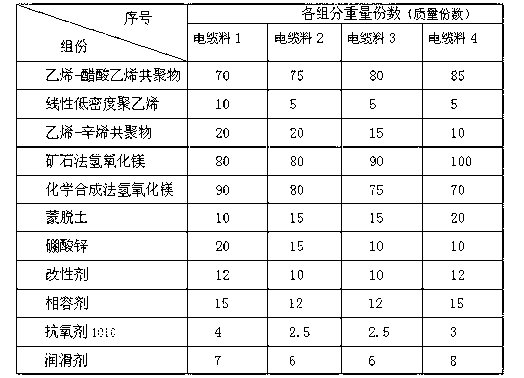

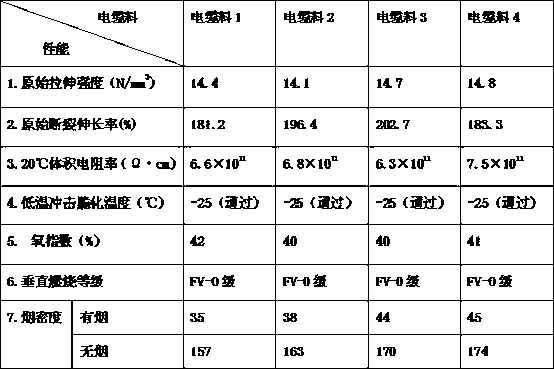

[0025] 1. Production example:

[0026] 1. Activation treatment:

[0027] Mix the silane coupling agent and the linear low density polyethylene powder evenly to form the modifier.

[0028] The modifier and ore method magnesium hydroxide (ie: micron magnesium hydroxide produced by ore method), chemical synthesis method magnesium hydroxide (ie: nano magnesium hydroxide produced by chemical synthesis method), montmorillonite, boric acid Add zinc into the mixer and stir at room temperature for 10-25 minutes to activate the surfaces of magnesium hydroxide, montmorillonite and zinc borate.

[0029] 2. Granulation:

[0030] The mixture obtained in the previous step and ethylene-vinyl acetate copolymer, linear low-density polyethylene, ethylene-octene copolymer, compatibilizer, antioxidant and lubricant are placed in a mixer for further mixing, and then Twin-screw extruder with forced feeding system for granulation.

[0031] Among them, the temperature of the twin-screw extruder gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com