Preparation method of foamable polyethylene terephthalate copolyester

A technology of ethylene glycol phthalate copolyester and terephthalic acid, which is applied in the field of polymer synthesis, can solve problems such as low melt viscosity and melt strength, easily broken foaming bubbles, and insufficient cooling, and achieve The effect of high molecular weight and high melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

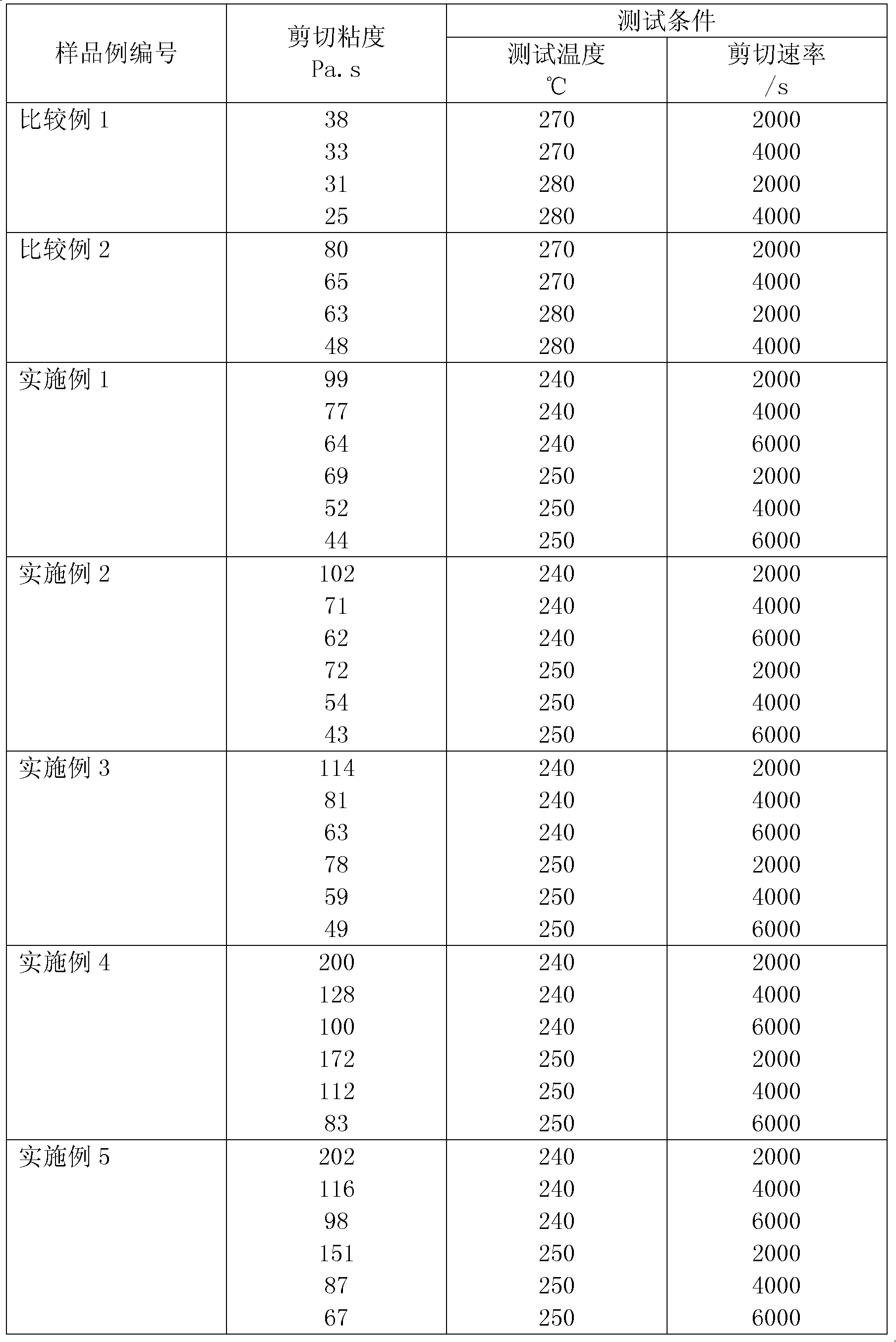

Examples

Embodiment 1

[0018] In a 20-liter polymerization reactor, 5100 grams of high-purity terephthalic acid, 900 grams of isophthalic acid, 3600 grams of ethylene glycol and 12 grams of trimellitic anhydride were added. To the reaction mixture was added 1.70 g of antimony glycolate. After replacing three times with high-purity nitrogen, adjust the initial pressure to 0.10Mpa. Heat to warm and stir. The esterification reaction is carried out at a pressure of 0.15-0.50Mpa and a temperature of 180-240°C. When the water output reaches 1200 grams, the pressure is released, the esterification reaction is completed, and the temperature is raised and the pressure is reduced. The polycondensation is carried out at an absolute pressure of 20-120 Pa and a temperature of 260-290° C., and the end point of the polycondensation reaction is determined according to the electric current of the stirring motor to obtain PET slices.

Embodiment 2

[0020] In a 20-liter polymerization reactor, add 4800 grams of high-purity terephthalic acid, 1200 grams of isophthalic acid, 3600 grams of ethylene glycol and 12 grams of trimellitic anhydride. To the reaction mixture was added 1.70 g of antimony glycolate. After replacing three times with high-purity nitrogen, adjust the initial pressure to 0.10Mpa. Heat to warm and stir. The esterification reaction is carried out at a pressure of 0.15-0.50Mpa and a temperature of 180-240°C. When the water output reaches 1200 grams, the pressure is released, the esterification reaction is completed, and the temperature is raised and the pressure is reduced. The polycondensation is carried out at an absolute pressure of 20-120 Pa and a temperature of 260-290° C., and the end point of the polycondensation reaction is determined according to the electric current of the stirring motor to obtain PET slices.

Embodiment 3

[0022] In a 20-liter polymerization reactor, 4800 grams of high-purity terephthalic acid, 900 grams of isophthalic acid, 265 grams of adipic acid, 3600 grams of ethylene glycol and 6 grams of trimellitic anhydride were added. To the reaction mixture was added 1.70 g of antimony glycolate. After replacing three times with high-purity nitrogen, adjust the initial pressure to 0.10Mpa. Heat to warm and stir. The esterification reaction is carried out at a pressure of 0.15-0.50Mpa and a temperature of 180-240°C. When the water output reaches 1200 grams, the pressure is released, the esterification reaction is completed, and the temperature is raised and the pressure is reduced. The polycondensation is carried out at an absolute pressure of 20-120 Pa and a temperature of 260-290° C., and the end point of the polycondensation reaction is determined according to the electric current of the stirring motor to obtain PET slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com