Method for preparing anisotropic bonded magnet by adopting pressure-keeping curing process

An anisotropic, pressure-holding and curing technology, used in the manufacture of inductors/transformers/magnets, permanent magnets, inorganic materials, etc. The effect of improved surface quality and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

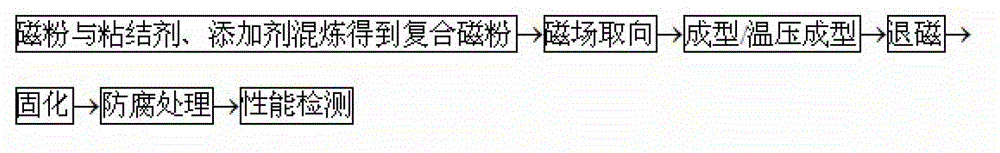

Method used

Image

Examples

Embodiment 1

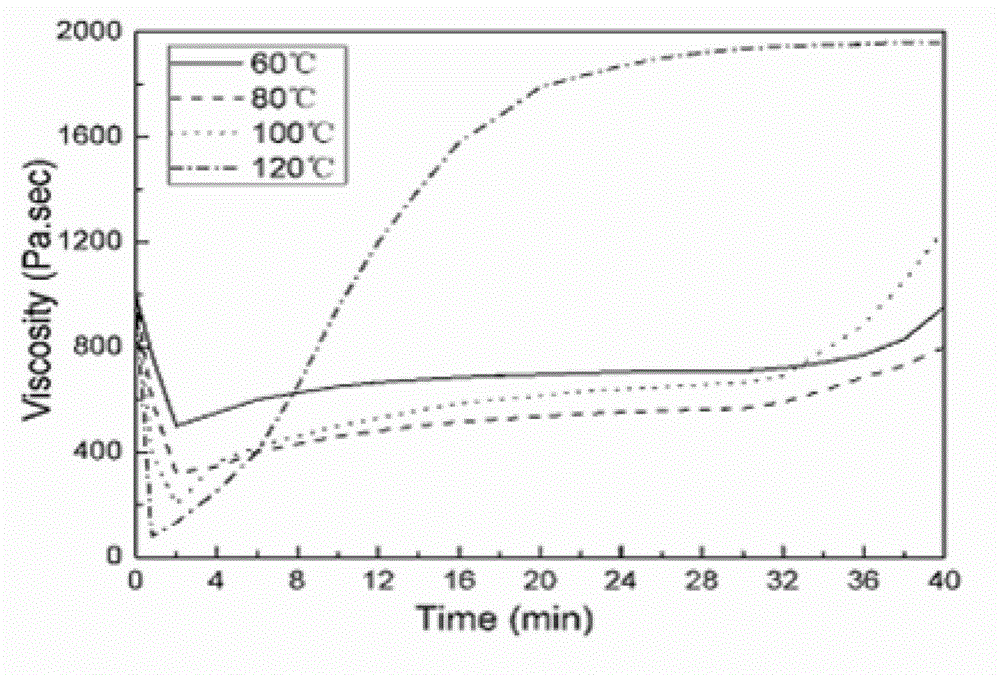

[0047]The magnetic powder is HDDR anisotropic NdFeB magnetic powder, the content of epoxy resin binder is 2.5% (mass fraction), the content of silane coupling agent is 0.5% (mass fraction), the temperature of warm pressing is 120℃, and the pressing pressure is 800MPa , the orientation magnetic field is 1.8T, and the pressure-holding and non-pressure-holding curing magnets are prepared respectively. The pressure-holding curing process is: temperature 120 ℃, time 30min and pressure 400MPa. The maximum magnetic energy product of the magnet before and after the pressure-holding is increased by 11.3%.

Embodiment 2

[0049] The magnetic powder is HDDR anisotropic NdFeB magnetic powder, the content of epoxy resin binder is 2.5% (mass fraction), the content of silane coupling agent is 0.5% (mass fraction), the pressing pressure is 800MPa, and the orientation magnetic field is 1.8T. The pressing time is 30min, and the holding pressure is 400MPa. After pressing and holding at room temperature and 120°C, the maximum energy product of the anisotropic bonded magnet cured at 120°C is increased by 76.9% compared with room temperature.

Embodiment 3

[0051] The magnetic powder is HDDR anisotropic NdFeB magnetic powder, the content of epoxy resin binder is 2.5% (mass fraction), the content of silane coupling agent is 0.5% (mass fraction), the temperature of warm pressing is 120℃, and the pressing pressure is 800MPa , the orientation magnetic field is 1.8T, under the pressure of 120 ℃ and 400MPa, the pressure is cured for 2min and 20min, respectively. Compared with the magnet for 2min, the maximum energy product of the magnet for 20min is increased by 7.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com