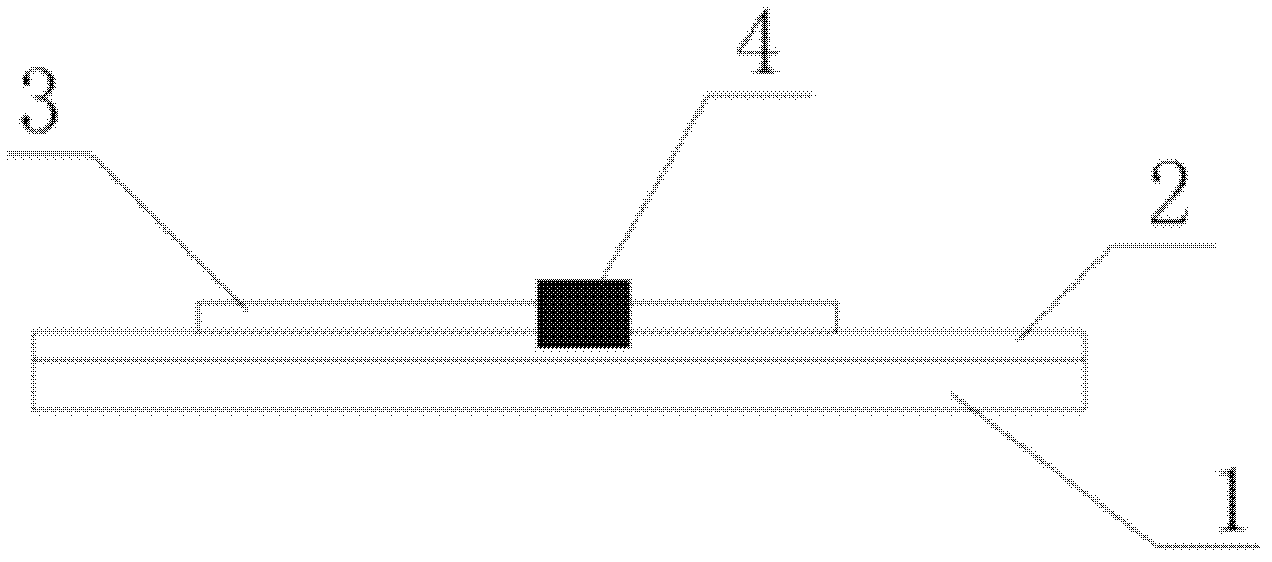

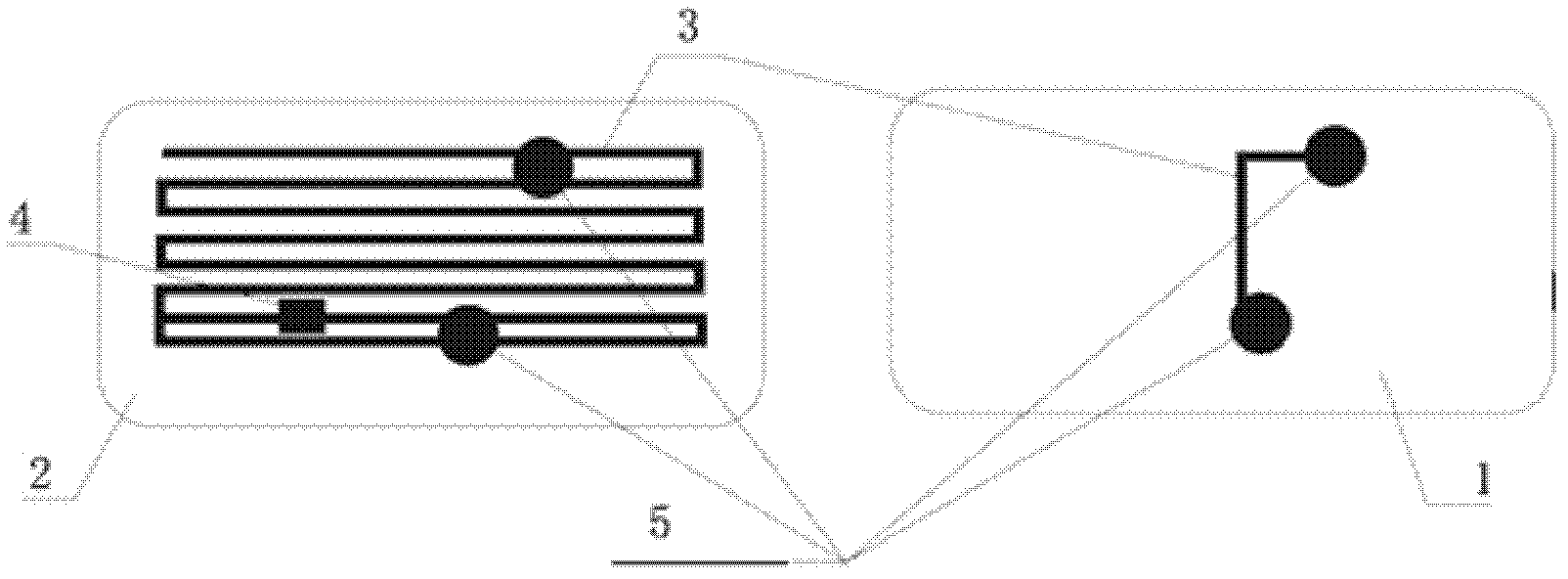

Radio frequency identification tag having diversion-proof function and manufacturing method thereof

一种无线射频、识别标签的技术,应用在无线射频识别电子标签及其制备领域,能够解决失去防伪及物流管理、难区别、限制等问题,达到过桥效果好、减少下降或损坏的机率、提高成品率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Using PET film as the support layer material, add the components of the release layer into the solvent ethyl acetate, mix them, and use a coating machine to coat them on the support layer;

[0054] The release layer material weight percentage is composed of:

[0055]

[0056] The total mass solid content of each component of the release layer is 25%;

[0057] The light-curing acrylic resin is DY5300 of Dongyang Chemical;

[0058] Dry in an infrared oven, dry at 100°C for 5 minutes, and then use a UV curing equipment with a power of 5 kilowatts for curing. The curing time is 10 seconds, and the coating thickness is 20 microns;

[0059] Use 400-mesh screen-printed conductive silver paste on the re-release layer, dry it at 100°C to form an RFID antenna, and bond the RFID chip with a thermosetting conductive adhesive, and then heat-press and cure at a temperature of 160°C , the hot pressing time is 8 seconds;

[0060] Use the RFID reader that matches the chip to enter...

Embodiment 2

[0063] Using PET film as the support layer material, add each component of the release layer to the solvent butyl acetate, mix, and use a coating machine to coat on the support layer;

[0064] The release layer material weight percentage is composed of:

[0065]

[0066] The total solid content of each component of the release layer is 35%;

[0067] The light-curing polyurethane is DY6200 of Dongyang Chemical;

[0068] It is dried in an infrared drying tunnel, dried at 100°C for 3 minutes, and then cured with a UV curing equipment with a power of 10 kilowatts. The curing time is 5 seconds, and the coating thickness is 20 microns;

[0069] Then compound the 16-micron thick aluminum foil with the above-mentioned release layer through an adhesive, and then print the antenna pattern on the aluminum foil by gravure printing, and form an etched antenna after acid or alkali etching and deinking treatment; then the RFID chip Bonding with thermosetting conductive adhesive, and cur...

Embodiment 3

[0073] Using PET film as the support layer material, add the components of the release layer into the solvent xylene, mix them, and use a coating machine to coat them on the support layer;

[0074] The release layer material weight percentage is composed of:

[0075]

[0076] The total solid content of each component of the release layer is 30%;

[0077] The light-curing acrylic resin is UV1201 of Yantai Ruihua Chemical;

[0078] Dry in an infrared oven, dry at 90°C for 5 minutes, and then use a UV curing equipment with a power of 10 kilowatts for curing. The curing time is 15 seconds, and the coating thickness is 30 microns;

[0079] Then use 500-mesh screen printing conductive silver paste as the seed layer on the release layer, dry it at 100°C, and then deposit copper on the seed layer by chemical deposition to form an electroless copper-plated antenna; then pass the RFID chip through The thermosetting conductive adhesive is bonded and cured by hot pressing. The hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com