Gluconobacter oxydans engineering bacteria and preparation method and application thereof in preparing xylitol

A technology of Gluconobacter oxydans and a construction method, applied in the field of bioengineering, can solve the problems of low concentration and total amount of coenzyme NADH, low XDH activity, incomplete tricarboxylic acid cycle pathway, etc., achieving simple operation and solving transformation problems. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

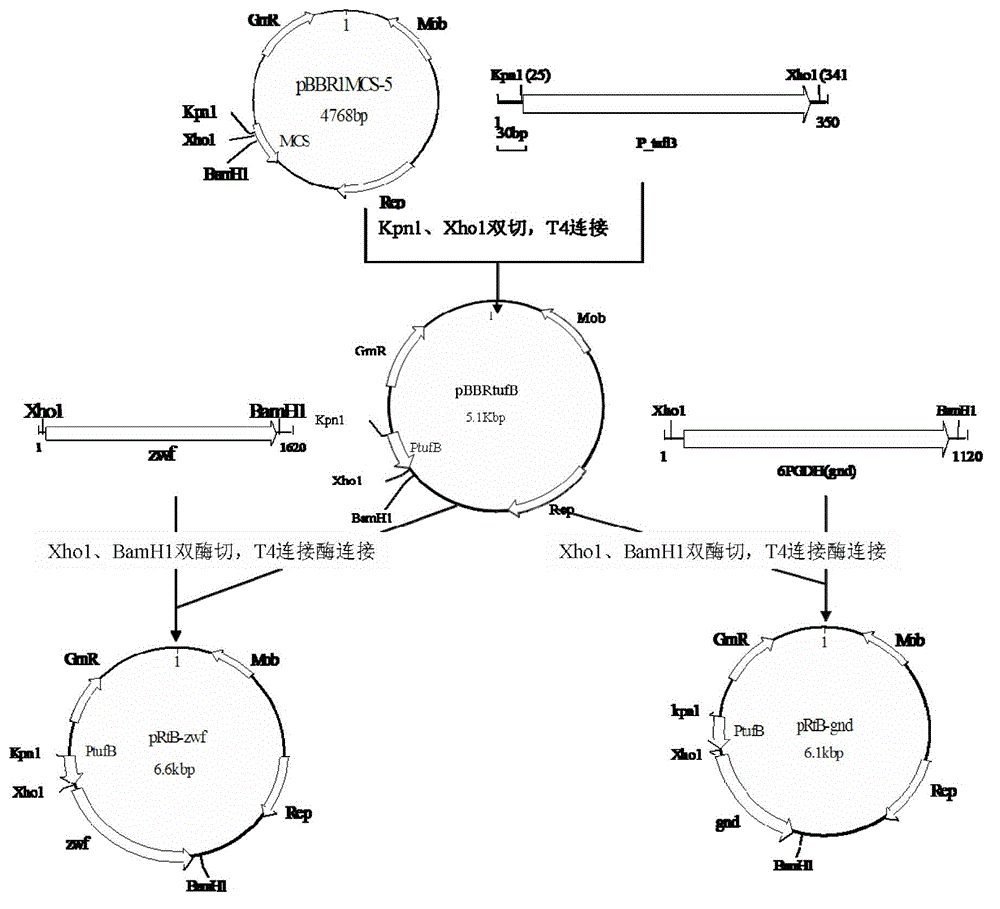

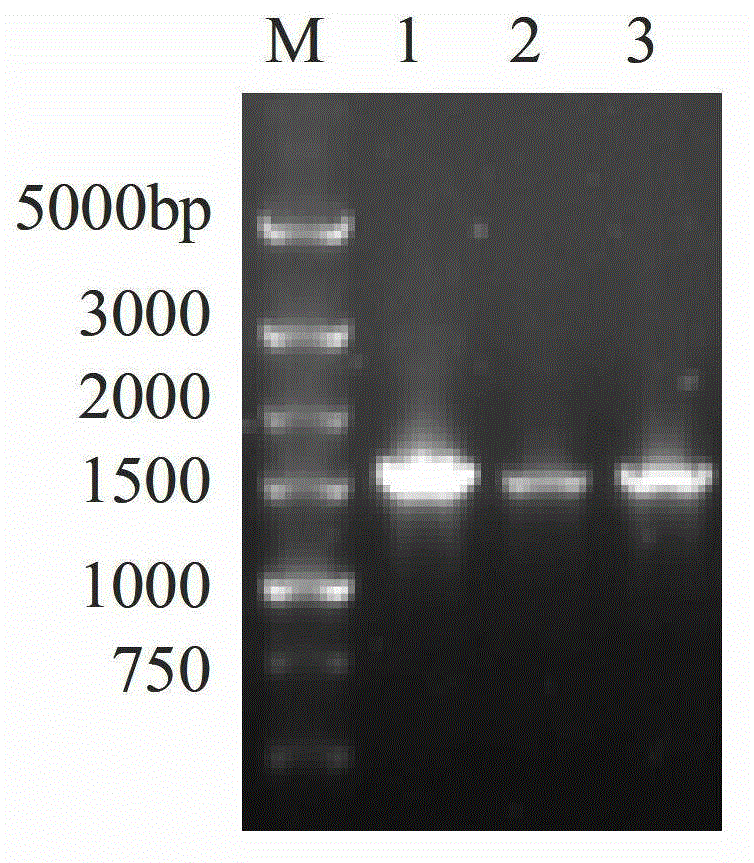

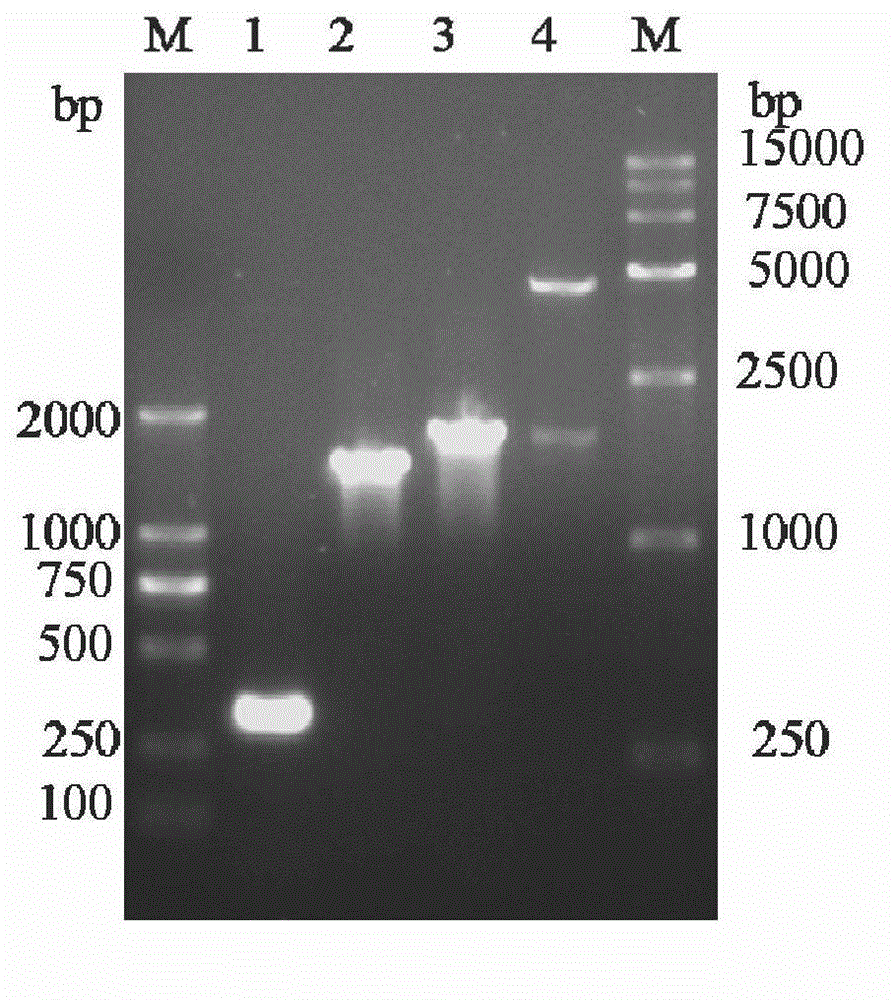

[0039] Example 1: Construction of expression vectors.

[0040] P tufB , gox0145 gene sequence design primers to clone each gene fragment, the primer sequences used are shown in Table 1;

[0041] Table 1

[0042]

[0043] The reaction system is as follows: 10×PCR buffer5μL, Mg 2+ 4 μL, dNTP 4 μL, upstream and downstream primers 2 μL each, exTaq DNA polymerase 0.5 μL, genome template 1 μL, add ddH 2 O to a total reaction volume of 50 μL.

[0044] The PCR reaction conditions are: 95°C for 2min; 94°C for 30s; 55°C for 30s; 72°C for 1min; cycle 30 times; 72°C for 10min;

[0045] The cloned gene fragments and the extracted plasmid pBBR1MCS-5 were purified and recovered. Digest plasmid pBBR1MCS-5 and promoter fragment P with restriction enzymes KpnⅠ and XhoⅠ tufB , After the gel was cut and recovered, it was incubated with T4ligase at a constant temperature for the ligation reaction, and the resulting ligation solution was transformed into competent cells E.coli JM109, and t...

Embodiment 2

[0046] Embodiment 2: Transformation of recombinant engineered bacteria.

[0047] The transfer of recombinant plasmids between Escherichia coli and Gluconobacter oxydans (G. oxydans) can achieve conjugative transfer through the help of the plasmid pRK2013. The transformation method is called three-parent conjugation. (1) Bacteria culture: inoculate the donor bacteria (E.coli BL21 with recombinant plasmid), helper bacteria HB101 / pRK2013 in LB with corresponding antibiotics and culture for 8 hours, and acceptor bacteria NH-10 in the culture medium After culturing for 18 hours, conjugation experiments were carried out. (2) Three-parent conjugation: Take 1.5mL of the above-mentioned recipient parent bacterial solution, centrifuge to collect the bacterial cells, wash with normal saline twice, pour off the liquid, add 0.5mL of helper bacteria, mix well, centrifuge, add 1.5mL of donor bacteria and centrifuge , wash once with liquid medium, mix well, take a part of the liquid and appl...

Embodiment 3

[0048] Example 3: Fermentation and harvest of recombinant engineered bacteria.

[0049] Seed medium and slant medium (g / L): glucose 20, yeast powder 5, peptone 3; the amount of agar added to the solid medium was 1.5%. YPG medium (g / L): Glucose 30, yeast powder 10, sorbitol 10, ammonium sulfate, potassium dihydrogen phosphate, magnesium sulfate heptahydrate trace (total 0.1~0.5). After adjusting the pH of the medium to 6.0-6.5, it was sterilized at 121°C; when the temperature of the medium used to cultivate recombinant bacteria dropped to 50-60°C, gentamicin and cephalosporin of corresponding concentrations were added.

[0050] Inoculate the activated strains G. oxydans NH-10 and G. oxydans pnadh-5 into the seed medium and incubate at a constant temperature for 18 hours until the middle and late logarithmic growth, and inoculate the fermentation medium at a ratio of 10% (v / v) Medium fermentation culture. Fermentation tank fermentation: YPG medium, on a 7.5L fermenter tank, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com