Novel bulk molding compound and preparation method thereof

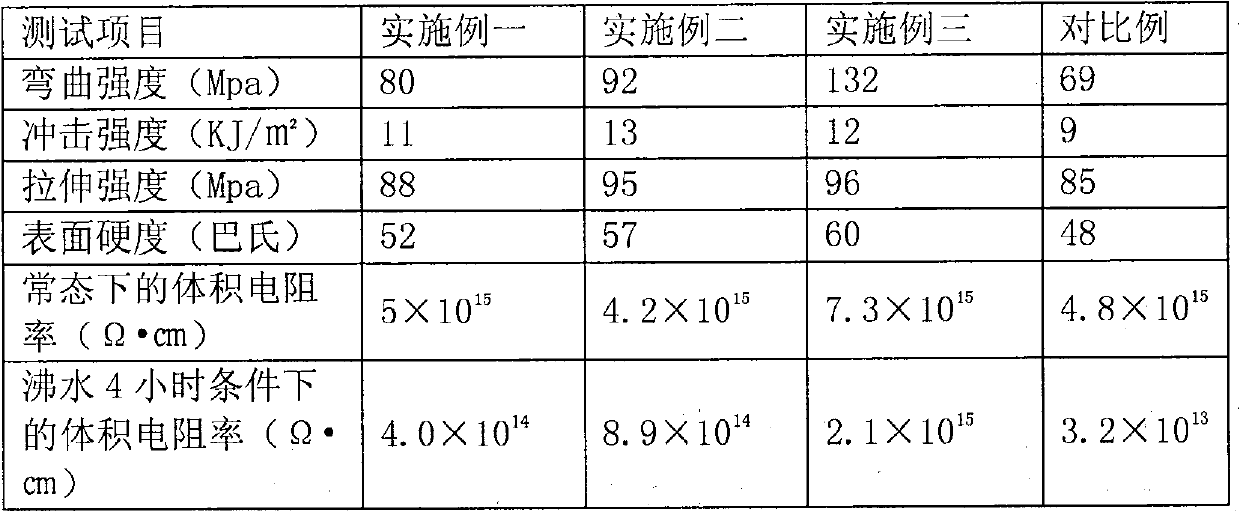

A slug molding compound and a new type of technology are applied in the field of new slug molding compound and its preparation, which can solve the problems of poor electrical properties, poor surface hardness and poor wear resistance of molded products, and achieve high surface hardness and excellent electrical properties. , the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

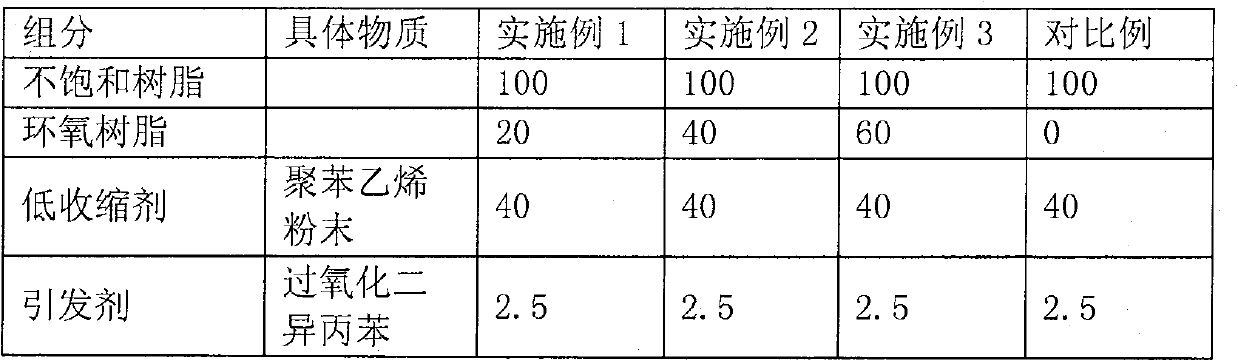

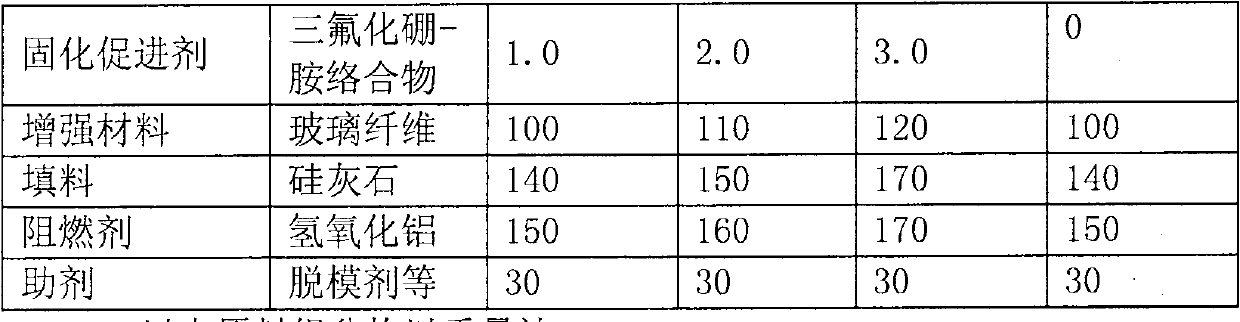

Embodiment 1

[0027] A preparation method for preparing a novel bulk molding compound, the novel bulk molding compound is produced through the following steps:

[0028] (1) Mixing: 100 parts of unsaturated polyester resin, 20 parts of epoxy resin, 40 parts of polystyrene powder, 2.5 parts of dicumyl peroxide, and 1.0 parts of boron trifluoride-amine complex , after measuring 30 parts of additives, mix at high speed for 10-20 minutes;

[0029] (2) Kneading and mixing: The liquid components mixed at high speed are added to a biaxial kneading device, and 140 parts of wollastonite, 150 parts of aluminum hydroxide, and 100 parts of glass fiber are added in sequence, kneading and mixing, and the mixing time is 10 to 20 minutes. ≤50℃;

[0030] (3) Extrusion preforming: using an extruder to make strips and wrapping them individually with plastic film;

[0031] (4) Packing: packed in special barrier bags after measurement.

[0032] The above raw material components are all measured by weight.

Embodiment 2

[0034] A preparation method for preparing a novel bulk molding compound, the novel bulk molding compound is produced through the following steps:

[0035] (1) Mixing: 100 parts of unsaturated polyester resin, 40 parts of epoxy resin, 40 parts of polystyrene powder, 2.5 parts of dicumyl peroxide, and 2.0 parts of boron trifluoride-amine complex , after measuring 30 parts of additives, mix at high speed for 10-20 minutes;

[0036] (2) Kneading and mixing: the high-speed mixed liquid components are added to a biaxial kneading device, and 150 parts of wollastonite, 160 parts of aluminum hydroxide, and 110 parts of glass fiber are added in sequence, kneading and mixing, and the mixing time is 10 to 20 minutes. ≤50℃;

[0037] (3) Extrusion preforming: using an extruder to make strips and wrapping them individually with plastic film;

[0038] (4) Packing: packed in special barrier bags after measurement.

[0039] The above raw material components are all measured by weight.

Embodiment 3

[0041] A preparation method for preparing a novel bulk molding compound, the novel bulk molding compound is produced through the following steps:

[0042] (1) Mixing: 100 parts of unsaturated polyester resin, 60 parts of epoxy resin, 40 parts of polystyrene powder, 2.5 parts of dicumyl peroxide, 3.0 parts of boron trifluoride-amine complex , after measuring 30 parts of additives, mix at high speed for 10-20 minutes;

[0043] (2) Kneading and mixing: The liquid components mixed at a high speed are added to a biaxial kneading device, and 170 parts of wollastonite, 170 parts of aluminum hydroxide, and 120 parts of glass fiber are added in sequence, kneading and mixing, and the mixing time is 10 to 20 minutes. ≤50℃;

[0044] (3) Extrusion preforming: using an extruder to make strips and wrapping them individually with plastic film;

[0045] (4) Packing: packed in special barrier bags after measurement.

[0046] The above raw material components are all measured by weight.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com