Porous inorganic coating/polyolefin microporous membrane compound diaphragm and preparation method thereof

A technology of polyolefin microporous membrane and inorganic coating, which is applied in the direction of coating, structural parts, battery pack components, etc. It can solve the problems of poor bonding force of the base film, affect the performance of lithium batteries, and easy to drop powder, etc., and achieve the appearance Dimensional stability, improved battery safety, and improved thermal stability at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] A polyethylene diaphragm with a thickness of 18 μm, a width of 300 mm, and a porosity of 45% produced by thermally induced phase separation technology (wet process) is selected as the base film; the coating with a water-based adhesive formula is used for coating; when coating, 200 Purpose For gravure roller printing, the ratio of coating speed to gravure roller (speed ratio) is 1:1; after the coating is coated, the diaphragm is cured in a drying oven with a total length of 12 meters, and the curing temperature is controlled at 60°C;

[0064] The processing speed of the atmospheric pressure glow discharge low temperature plasma surface treatment device is synchronized with the paint coating speed, which is 2m / min. Plasma surface treatment power 50W;

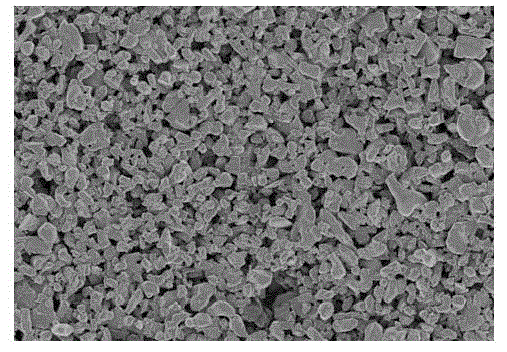

[0065] The surface SEM morphology of the obtained porous inorganic coating / polyolefin microporous membrane composite membrane is shown in Figures 2(a) and 2(b), and the cross-sectional SEM morphology is shown in Figure 2(a)...

Embodiment 2

[0067] A polyethylene diaphragm with a thickness of 18 μm, a width of 300 mm, and a porosity of 45% is used as the base film; a coating with a water-based adhesive formula is selected for coating; when coating, a 200-mesh gravure roll is used, and the coating speed is the same as that of the gravure roll. The speed ratio (speed ratio) is 1:1; after the coating is coated, the diaphragm is cured in a drying oven with a total length of 12 meters, and the curing temperature is controlled at 60°C;

[0068] The processing speed of the atmospheric pressure glow discharge low temperature plasma surface treatment device is synchronized with the paint coating speed, which is 2m / min. Plasma surface treatment power 100W. The properties of the obtained composite separator of porous inorganic coating / polyolefin microporous separator are listed in Table 1.

Embodiment 3

[0070] A polyethylene diaphragm with a thickness of 18 μm, a width of 300 mm, and a porosity of 45% is used as the base film; a coating with a water-based adhesive formula is selected for coating; when coating, a 200-mesh gravure roll is used, and the coating speed is the same as that of the gravure roll. The speed ratio (speed ratio) is 1:1; after the coating is coated, the diaphragm is cured in a drying oven with a total length of 12 meters, and the curing temperature is controlled at 60°C;

[0071] The processing speed of the atmospheric pressure glow discharge low temperature plasma surface treatment device is synchronized with the paint coating speed, which is 2m / min. Plasma surface treatment power 200W. The properties of the obtained composite separator of porous inorganic coating / polyolefin microporous separator are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com