Ceramic wall tile prepared by using industrial waste residue of aluminum profiles and preparation method thereof

A technology of industrial waste residue and aluminum profiles is applied in the field of ceramic wall tiles, which can solve the problem of low strength and achieve the effects of improving flexural strength, reducing cost and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing ceramic wall tiles by utilizing industrial waste slag of aluminum profiles comprises the following steps:

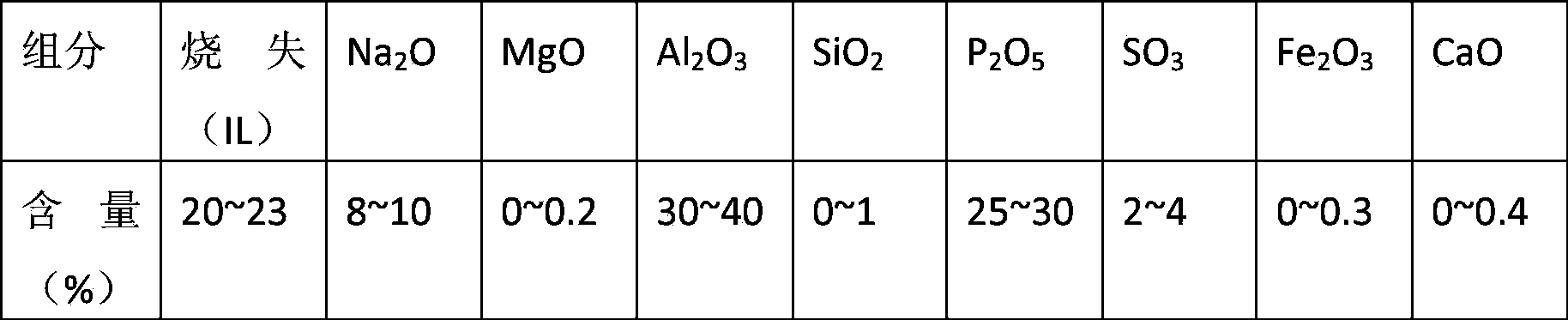

[0028] (1) Take 20kg of industrial waste residue from an aluminum profile factory in South China and dry it at 150°C, then calcinate it in a high-temperature furnace at 1000°C (hold for 1 hour, the heating rate during calcination is 500°C per hour, directly from room temperature to calcination temperature), after natural cooling, the aluminum profile industrial waste slag clinker is obtained; then the clinker is ball milled, the ball milling time is 60min, the pulp is passed through a 80 mesh sieve, and after drying, it is granulated through a 20 mesh sieve to obtain the aluminum waste slag clinker , to be batched; the chemical composition of aluminum waste slag in the present embodiment is shown in Table 1.

[0029] Table 1 Composition of industrial waste residues from an aluminum profile factory in South China

[0030]

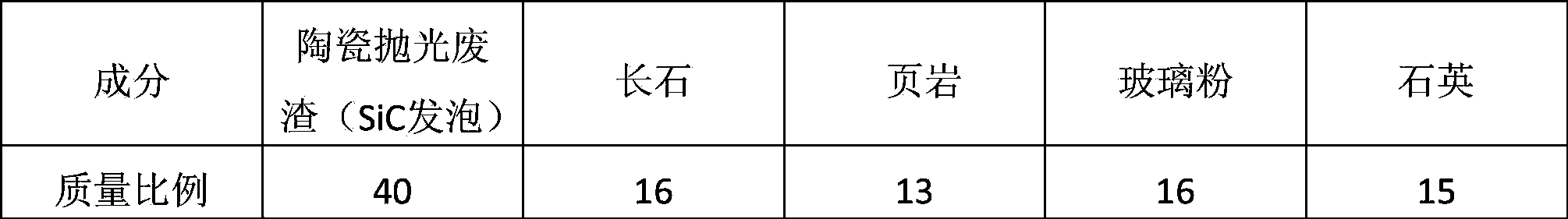

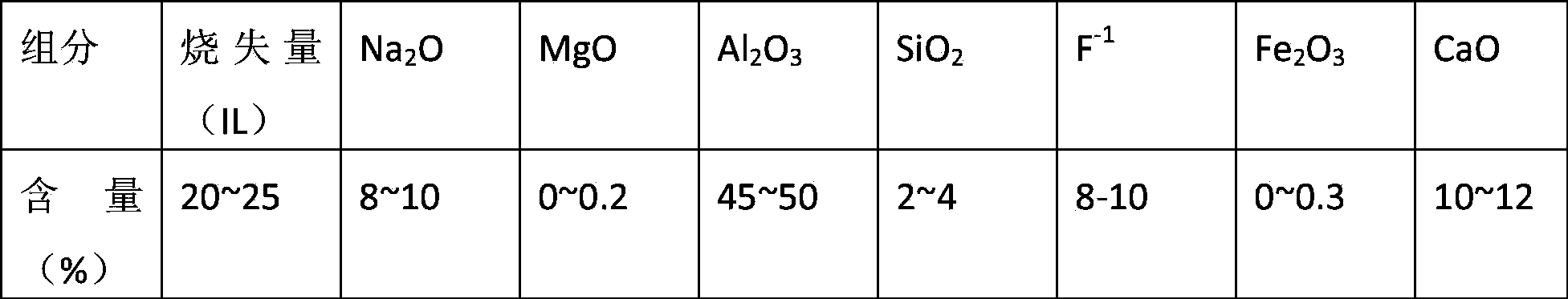

[0031] (2) P...

Embodiment 2

[0040] The difference between this embodiment and Example 1 is that aluminum profile industrial waste clinker: light white material: carboxymethyl cellulose (CMC): sodium tripolyphosphate (STPP) = 20: 80: 0.1: 0.3; firing The time heating system is as follows:

[0041]From room temperature to 500°C within 15 minutes, from 500°C to 800°C within 15 minutes; from 800°C to 1000°C within 20 minutes; from 1000°C to 1100°C within 25 minutes; from 1100°C within 5 minutes To 1140°C; keep at 1140°C for 25 minutes.

[0042] The lightweight material obtained in this embodiment has good surface effect and a specific gravity of 1.39g / cm 3 , the flexural strength (modulus of rupture) is 21.4MPa, the thermal conductivity is 0.5236 (W / mK), and the water absorption rate is 0.29%. (10-11MPa), the strengthening effect of aluminum waste slag is obvious.

Embodiment 3

[0044] The difference between this embodiment and Example 1 is that aluminum profile industrial waste clinker: light white material: carboxymethyl cellulose (CMC): sodium tripolyphosphate (STPP)=25: 75: 0.1: 0.3; The time heating system is as follows:

[0045] From room temperature to 500°C within 15 minutes, from 500°C to 800°C within 15 minutes; from 800°C to 1000°C within 20 minutes; from 1000°C to 1100°C within 30 minutes; from 1100°C within 5 minutes To 1140°C; keep warm at 1140°C for 30min.

[0046] The lightweight material obtained in this embodiment has good surface effect and a specific gravity of 1.41g / cm 3 , the flexural strength (modulus of rupture) is 20.3MPa, the thermal conductivity is 0.7246 (W / mK), and the water absorption rate is 0.36%. (10-11MPa), the strengthening effect of aluminum waste slag is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com