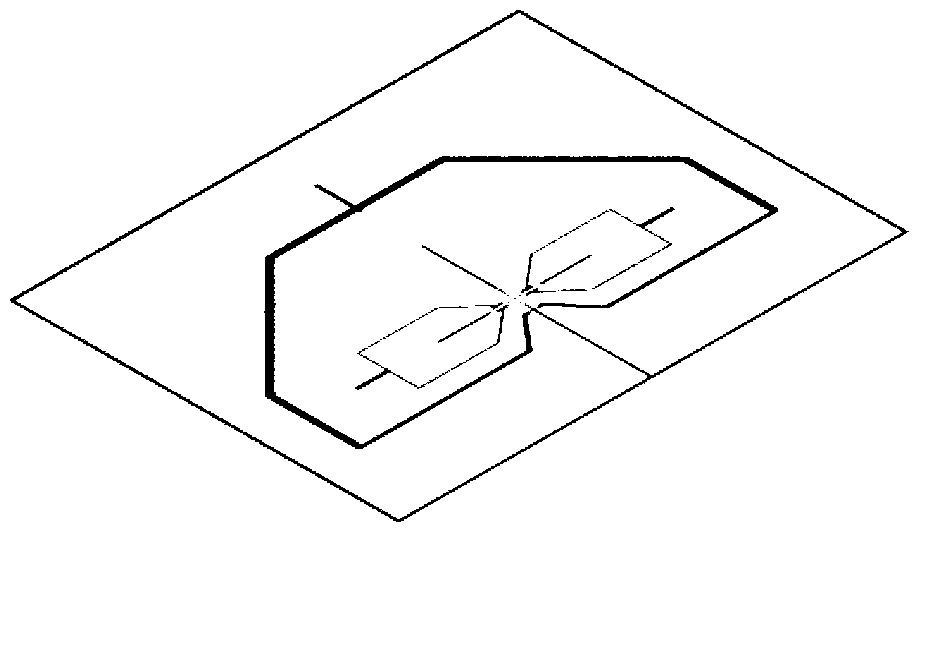

Method and dedicated chip for preparation of micron calcium alginate filament based on microfluidic chip

A technology of microfluidic chips and calcium alginate, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

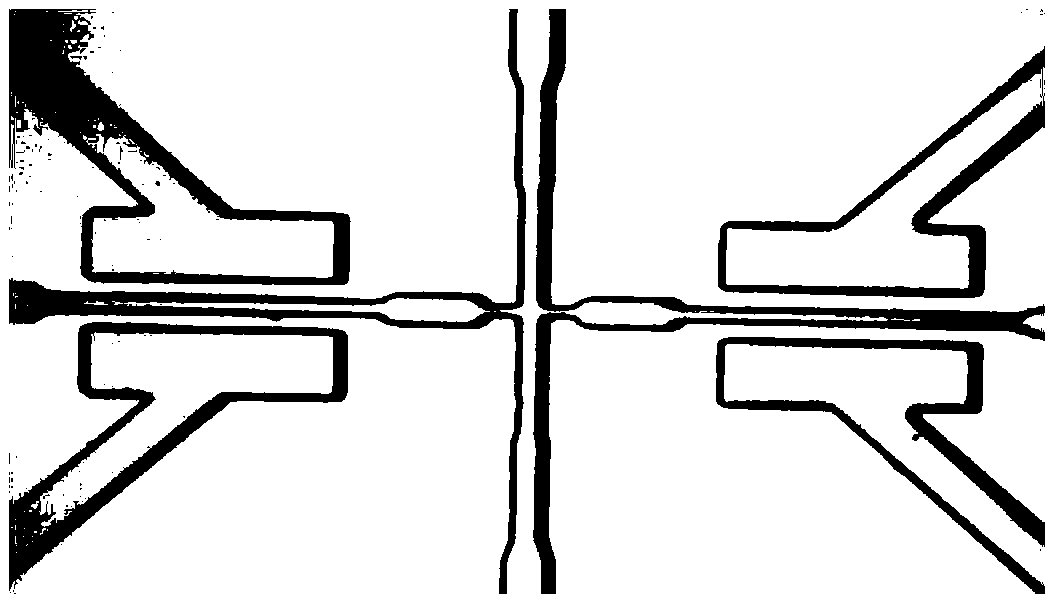

Method used

Image

Examples

Embodiment 1

[0027] Mineral oil droplets of two different colors are arranged alternately within calcium alginate microfilaments.

[0028] Stained by adding Sudan orange and Sudan black respectively to mineral oil. Two mineral oils of different colors were passed into inlet 1 and inlet 2 of the chip droplet dispersion phase respectively. Program the air pump valve controller, the two air pump valve control units squeeze the dispersed phase channel once every 400ms, and the extrusion time interval between the two units is 200ms, and set the flow rate of the three continuous phases of sodium alginate solution to 1ul / min , the flow rate of the continuous phase of the sodium alginate solution in the cross-shaped droplet spacing adjustment unit is 1ul / min. The concentration of sodium alginate solution used is 2% (w / w). The chip is placed flat, and the outlet is immersed in a calcium chloride solution with a concentration of 4% (w / w). The width and height of the outlet are both 200um. Calcium ...

Embodiment 2

[0030] Droplets of two different compositions are arranged alternately within calcium alginate microfilaments.

[0031] Pass NOA63 photoresist liquid and FC-40 fluorocarbon oil into inlet 1 and inlet 2 of the chip droplet dispersion phase respectively. Program the air pump valve controller, the two air pump valve control units squeeze the dispersed phase channel once every 400ms, and the extrusion time interval between the two units is 200ms, and set the flow rate of the three continuous phases of sodium alginate solution to 1ul / min , the flow rate of the continuous phase of the sodium alginate solution in the cross-shaped droplet spacing adjustment unit is 1ul / min. The concentration of sodium alginate solution used is 2% (w / w). The chip is placed flat, and the outlet is immersed in a calcium chloride solution with a concentration of 4% (w / w). The width and height of the outlet are both 200um. Calcium alginate microfilaments containing interphase droplets of NOA63 and FC-40 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com