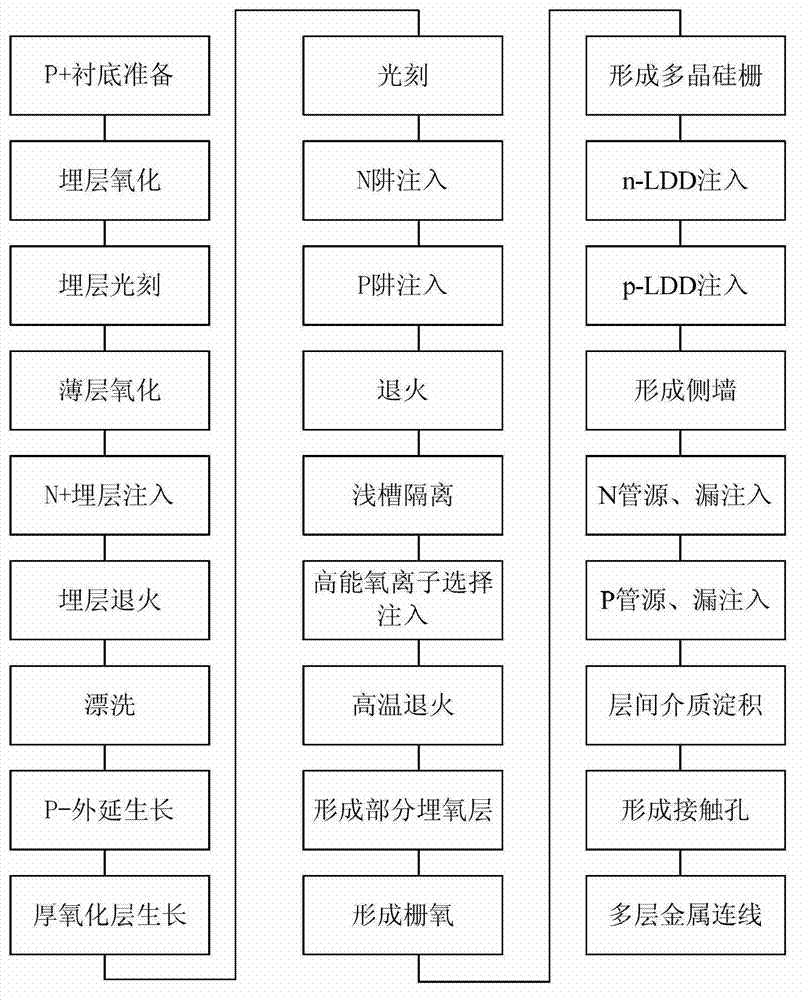

Anti-single-particle-radiation MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) apparatus and preparation method

An anti-single particle radiation and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of device threshold voltage drift, total dose of deterioration, warpage, etc., and achieve pulse time width narrowing and weakening Self-heating effect, weakening effect of floating body effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

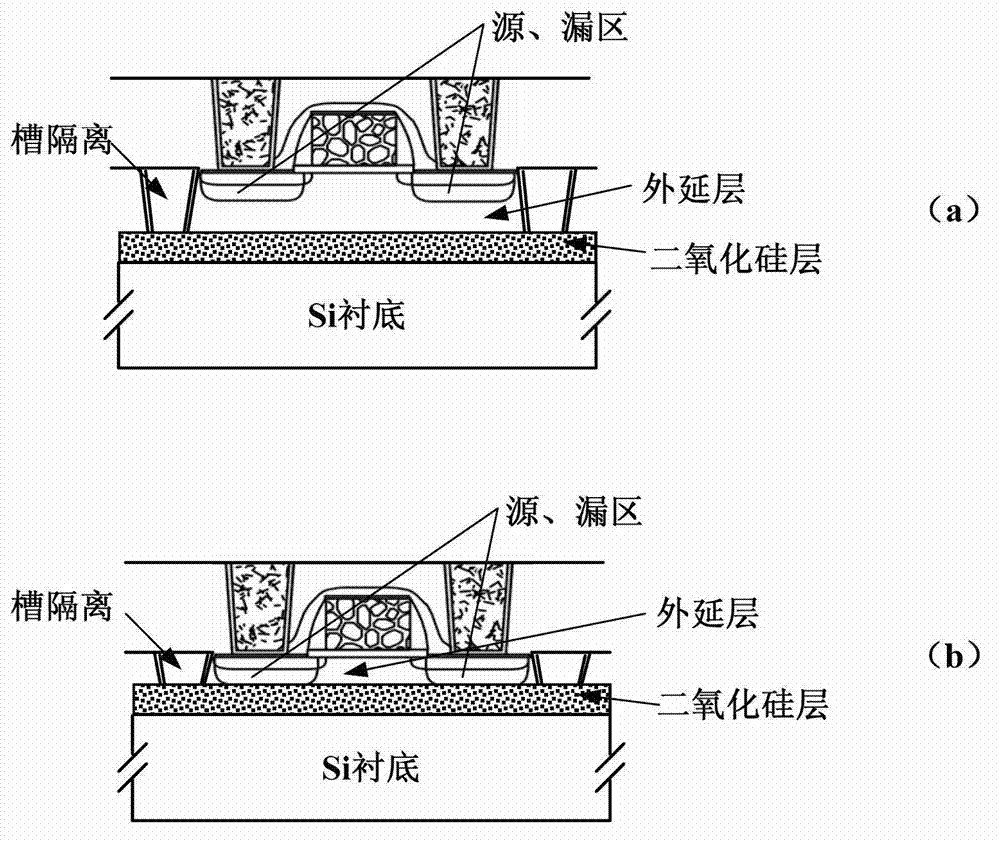

[0033] The substrate is a p+ type silicon wafer 101, doped with boron, with a concentration of 1e18cm -3 ; Doped with arsenic to form an n+ buried layer 105 with a thickness of 1 μm and a concentration of 6e18cm -3 ; An epitaxial layer 102 with a thickness of about 4.0 μm is epitaxially grown, boron-doped with a concentration of 1e16cm -3 ; Photolithography out of the N well region, the first dose is 5e13cm -2 , the energy is 2MeV phosphorus doping, and then the energy is 0.75MeV again, the dose is 5e12cm -2 Phosphorus doping; photoetching out the P well region, the first dose is 8e13cm -2 , boron doping with an energy of 1.5MeV, and then again with an energy of 0.3MeV and a dose of 6e12cm -2 Boron doping, followed by high-temperature annealing at 1100°C for 30 minutes to form a doped n-well 103 and a p-well 104 with a depth of 3 μm. The relationship between the concentration and depth of the p-well is as follows Figure 10 shown; complete deep trench isolation.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com