Reticle and forming method of semiconductor device

A technology of reticles and semiconductors, which is applied in the direction of equipment, photographic process of patterned surface, and originals used for photomechanical processing, etc. It can solve the problems of overlay accuracy deviation and reduce the ability of imaging system to form accurate patterns, etc., to achieve Improved accuracy, reduced self-heating effect, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

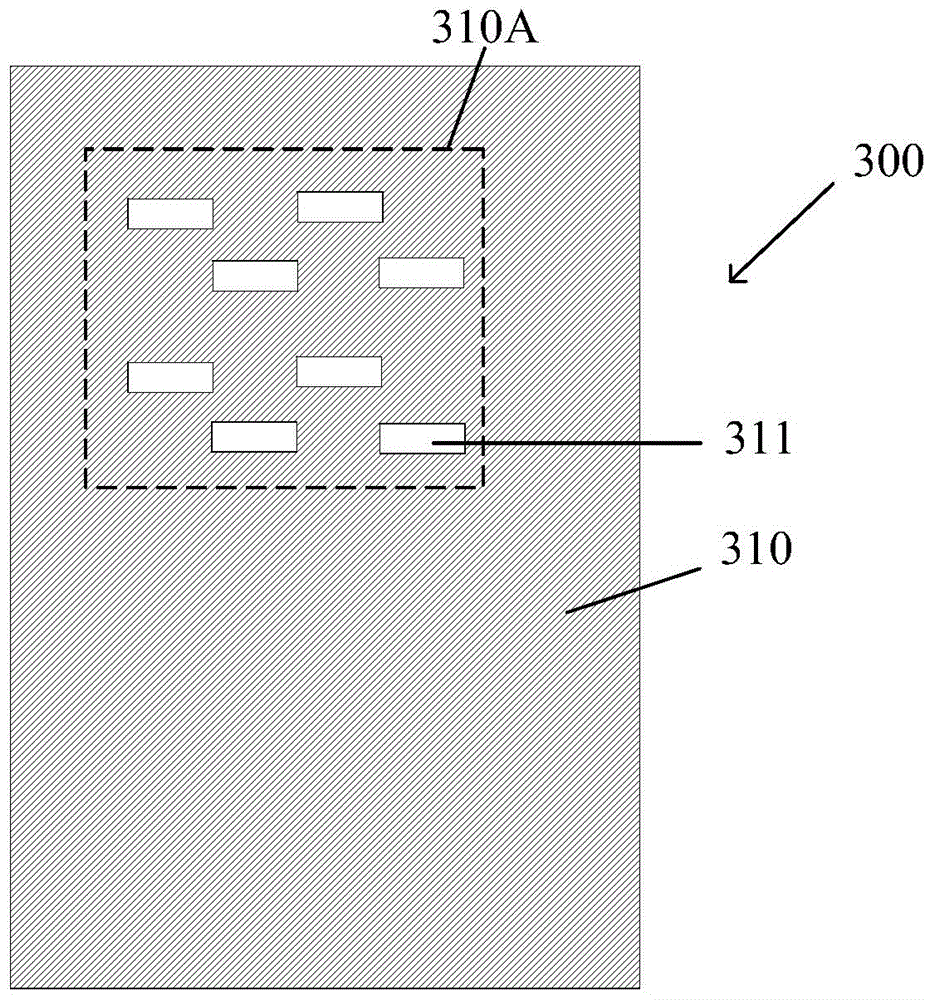

[0043] As mentioned in the background technology, some internal reasons of the existing reticle structure, as well as the influence of factors such as the temperature difference of the reticle at different exposure times, reduce the ability of the imaging system to form accurate patterns, resulting in large overlay accuracy errors .

[0044] A reticle generally includes a substrate and a light-shielding layer on the substrate. The shading layer includes a graphic area (the graphic area can also be called a window area or an opening area) and a non-graphic area (the non-graphic area can also be called a non-window area or a non-opening area).

[0045] After analysis, the overlay accuracy error is usually caused by the self-heating effect of the mask. The reason for the self-heating effect of the reticle is as follows: when the reticle is subjected to short-wavelength light such as deep ultraviolet (DUV) light or extreme ultraviolet (EUV) light, the non-patterned area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com