Amorphous alloy transformer core with cylindrical structure and vibration monitoring method thereof

A technology of amorphous alloy and transformer, which is applied in the field of cylindrical structure amorphous alloy transformer core and its vibration monitoring. It can solve the problems of high-capacity amorphous alloy transformer cost increase, affecting mechanical properties, and low filling rate, so as to improve material utilization. High efficiency, reduced processing difficulty, and strong short-circuit resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

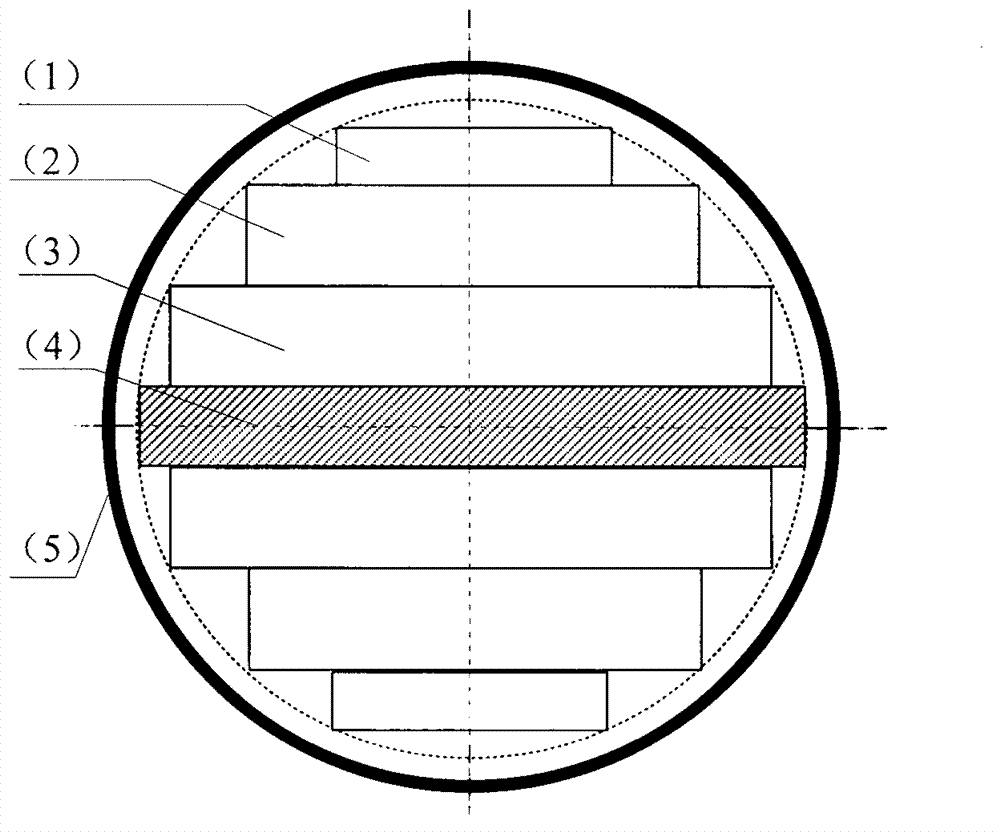

[0024] like figure 1 As shown, the transformer core has a stepped cylindrical structure, which is composed of high magnetic permeability pull plates and amorphous alloy strips with widths of 213mm, 170mm, and 142mm, respectively. The main stage of the circular core adopts high magnetic permeability material as the pull plate, and a virtual core is added. The amorphous alloy strips on both sides of the main stage of the circular iron core are symmetrically distributed, and they are amorphous alloy strips with widths of 213mm, 170mm, and 142mm. And the high magnetic permeability pull plate and three kinds of amorphous alloy strips are combined into a stepped circle according to a certain ratio.

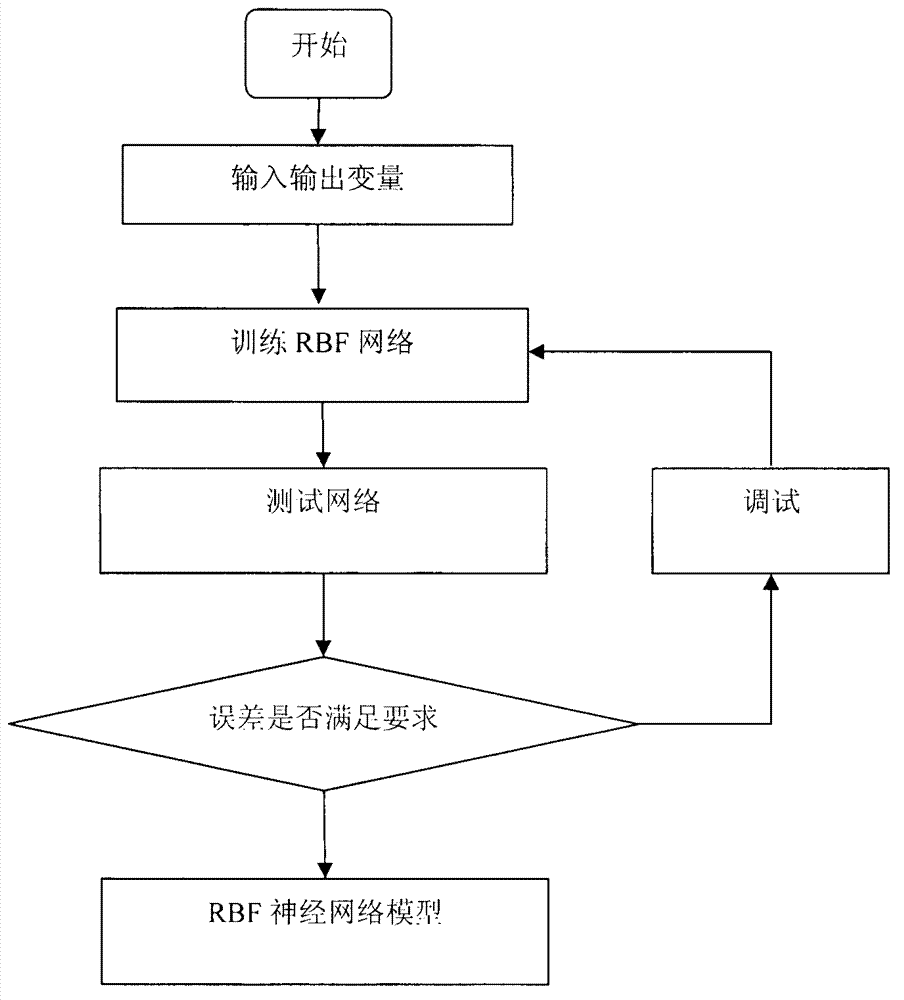

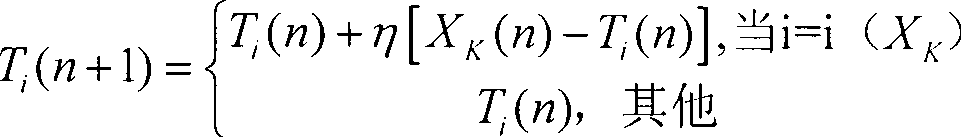

[0025] For online detection of vibration information, according to figure 2 As shown, the K-means clustering algorithm is first used to obtain the learning center of the basis function; the weight value is obtained by the LMS algorithm. Among them, the specific steps of the K-means ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stacking factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com