Processing method for high-efficiency polyester nonwoven thermal insulation material

A technology of polyester non-woven fabrics and thermal insulation materials, applied in the field of non-woven deep processing, can solve problems such as difficulties in large-scale production and application, difficulty in construction, mechanical defects, etc., achieve breakthroughs in technology and equipment bottlenecks, increase the ability of spontaneous drainage, The effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 120g / m 2 , thick 1mm polyester staple fiber needle-punched nonwovens

[0034] (1) Preparation of tetraethyl orthosilicate sol working solution

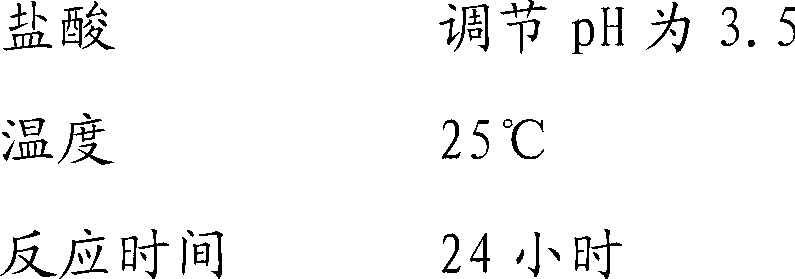

[0035]

[0036]

[0037] Then, add 5% (volume fraction) of CF 3 CH 2 CH 2 OH, fully stirred evenly to obtain a sol treatment working solution.

[0038] (2) Aminolytic modification of polyester nonwoven fabric

[0039]

[0040] After dehydration, the liquid carrying rate is controlled to 75%; specifically, in this embodiment, the catalyst is sodium carbonate.

[0041] (3) Impregnated sol treatment working solution

[0042] The temperature of the working fluid is 30°C, and the liquid carrying rate is 200%. The scraper spacing is 1mm.

[0043] (4) Ladder drying conditions

[0044] 50℃×60min, 80℃×20min, 110℃×20min, 160℃×2min.

[0045] The performance of the thermal insulation material prepared by the above process is:

[0046] The average diameter of micropores in the airgel is 60nm; the thermal conductivity at ...

Embodiment 2

[0048] 180g / m 2 , 1.5mm thick polyester needle-punched nonwovens

[0049] (1) Preparation of tetraethyl orthosilicate sol working solution

[0050]

[0051] Then, add 7% (volume fraction) of CF 3 CH 2 CH 2 OH, fully stirred evenly to obtain a sol treatment working solution.

[0052] (2) Aminolytic modification of polyester nonwoven fabric

[0053]

[0054] After dehydration, the liquid carrying rate is controlled to 70%; in this embodiment, the catalyst used is sodium carbonate.

[0055] (3) Impregnated sol treatment working solution

[0056] The temperature of the working fluid is 35°C, and the liquid carrying rate is 180%. The scraper spacing is 1.5mm.

[0057] (4) Ladder drying conditions

[0058] 50℃×90min, 80℃×20min, 110℃×20min, 160℃×3min.

[0059] The performance of the thermal insulation material prepared by the above process is:

[0060] The average diameter of the micropores in the airgel is about 80nm; the thermal conductivity at normal temperature a...

Embodiment 3

[0062] 75g / m 2 , 0.75mm thick polyester melt-blown nonwovens

[0063] (1) Preparation of tetraethyl orthosilicate sol working solution

[0064]

[0065] Then, 5% (volume fraction) of CF3CH2CH2OH was added and stirred evenly to obtain a working solution for sol treatment.

[0066] (2) Aminolytic modification of polyester nonwoven fabric

[0067]

[0068] After dehydration, the liquid carrying rate is controlled at 70%.

[0069] (3) Impregnated sol treatment working solution

[0070] The temperature of the working fluid is 35°C, and the liquid carrying rate is 150%. The scraper spacing is 0.75mm.

[0071] (4) Ladder drying conditions

[0072] 50℃×45min, 80℃×15min, 110℃×15min, 160℃×2min.

[0073] The performance of the thermal insulation material prepared by the above process is:

[0074] The average diameter of the airgel is about 60nm; the thermal conductivity at normal temperature and pressure is lower than 0.038w / m k; the longitudinal breaking strength is 160N / 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com