Calcium sulfate crystal whisker modified chlorosulfonated polyethylene rubber cable material

A technology of chlorosulfonated polyethylene and calcium sulfate whiskers, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor mechanical strength of cable materials, and achieve improved tensile stress, excellent flame retardancy and Effect of non-flammability, improvement of flame retardancy and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

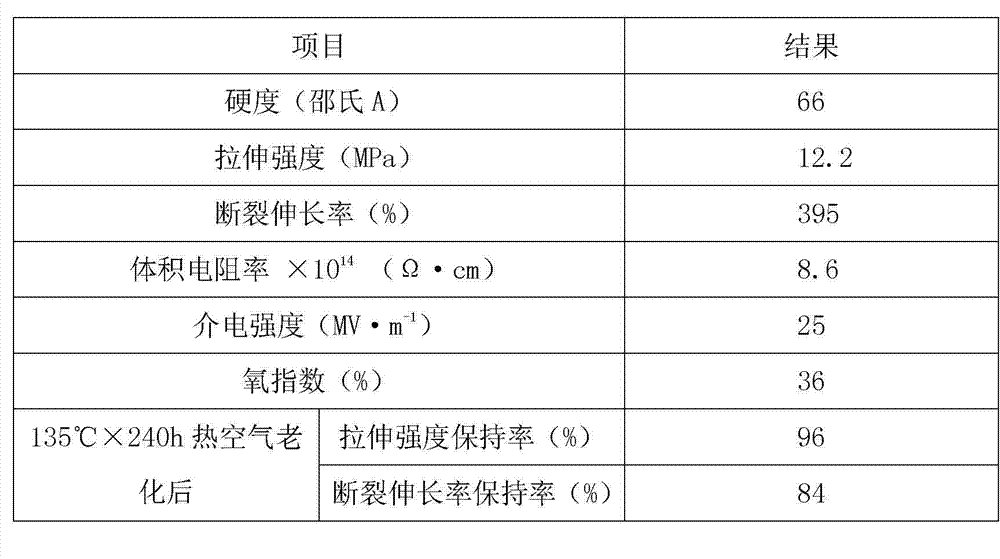

Examples

Embodiment

[0013] A calcium sulfate whisker modified chlorosulfonated polyethylene rubber cable material, made of the following raw materials in parts by weight: 108 parts of chlorosulfonated polyethylene rubber CSM2305, 24 parts of German Lanxess 9650 EPDM rubber, bromine 15 parts of butyl rubber 2244, 10 parts of n-octyl n-decyl adipate, 6 parts of tris(2-chloroethyl) phosphate, 12 parts of dibutyl maleate, 1.5 parts of sulfur, di-tert-butyl peroxide 6 parts of base, 3 parts of calcium oxide, 3 parts of zinc oxide, 2 parts of zinc stearate, 2 parts of dibasic lead stearate, 1.6 parts of 3-aminopropyltrimethoxysilane, titanate coupling agent 0.8 parts of TMC-TTS, 12 parts of antimony trioxide, 45 parts of calcium sulfate whiskers, 25 parts of talcum powder, 16 parts of nano wollastonite powder, 12 parts of carbon black N220, 1.5 parts of antioxidant 168, 1.5 parts of anti-aging agent DNP , 1.8 parts of anti-aging agent OD, 2.5 parts of accelerator M, 1.5 parts of accelerator ZDC, and 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com