Preparation method of TiO2 loaded nitric acid modified viscose-based activated carbon fiber cloth photocatalytic material

A technology of activated carbon fiber cloth and activated carbon fiber, which is applied in the field of photocatalytic materials, can solve the problems of poor catalytic effect, uneven loading of TiO2, and weak combination, so as to improve surface hydrophilicity, increase reaction conversion rate, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take a viscose-based activated carbon fiber with a size of 10cm*10cm, place it in a nitric acid solution with a concentration of 67% by mass, treat it in a constant temperature water bath at 80°C for 6 hours, wash it with water until the pH is neutral, and dry it in an oven. A viscose-based activated carbon fiber cloth modified with nitric acid was obtained.

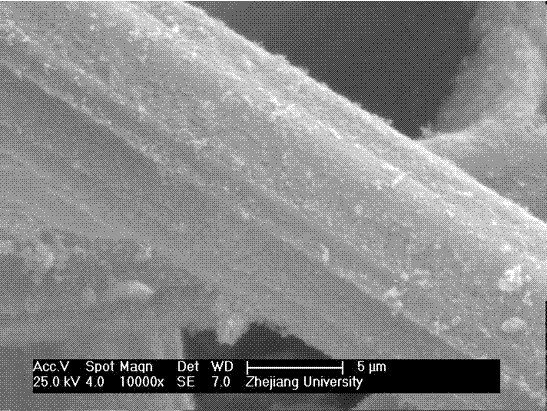

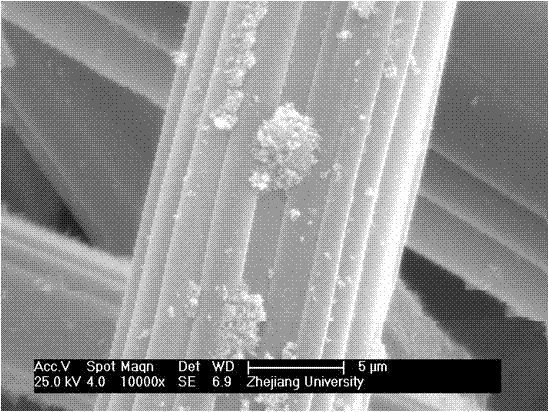

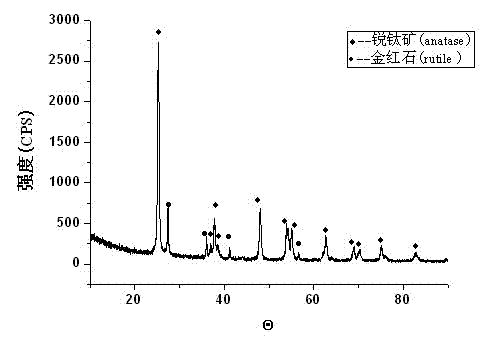

[0018] The viscose-based activated carbon fibers modified with nitric acid were placed in 4% TiO 2 (P25, Degussa Company) suspension, impregnated with supernatant, and dried in an oven to make a catalyst. XRD analysis ( figure 1 ) shows that TiO 2 Micro-anatase and rutile type maintained, SEM ( Figure 2(a) ) shows that TiO 2 Disperses well on activated carbon fibers. The catalyst photodegraded toluene for 6 hours, and the degradation rate was 52.6%.

Embodiment 2

[0020] Take a viscose-based activated carbon fiber with a size of 10cm*10cm, put it in a nitric acid solution with a mass percentage concentration of 9.2%, treat it in a constant temperature water bath at 80°C for 0.5h, wash it with water until the pH is neutral, and dry it in an oven Dry to obtain viscose-based activated carbon fiber cloth modified by nitric acid.

[0021] The viscose-based activated carbon fibers modified by nitric acid were placed in 0.5% TiO 2 (P25, Degussa Company) suspension, impregnated with supernatant, and dried in an oven to make a catalyst. The catalyst photodegraded toluene for 6 hours, and the degradation rate was 20.5%.

Embodiment 3

[0023] Take a viscose-based activated carbon fiber with a size of 10cm*10cm, place it in a nitric acid solution with a mass percentage concentration of 30%, treat it in a constant temperature water bath at 80°C for 3 hours, wash it with water until the pH is neutral, and dry it in an oven , to obtain viscose-based activated carbon fiber cloth modified by nitric acid.

[0024] Nitric acid-modified viscose-based activated carbon fibers were placed in TiO with a mass percent concentration of 1%. 2 (P25, Degussa Company) suspension, impregnated with supernatant, and dried in an oven to make a catalyst. The catalyst photodegraded toluene for 6 hours, and the degradation rate was 34.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com