Preparation method and application of compound electrode slice

A composite electrode and solution technology, applied in battery electrodes, capacitor electrodes, circuits, etc., can solve the problems of easy agglomeration and lamination, and achieve the effect of eliminating the coating process, simplifying the process, and reducing the equivalent series resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

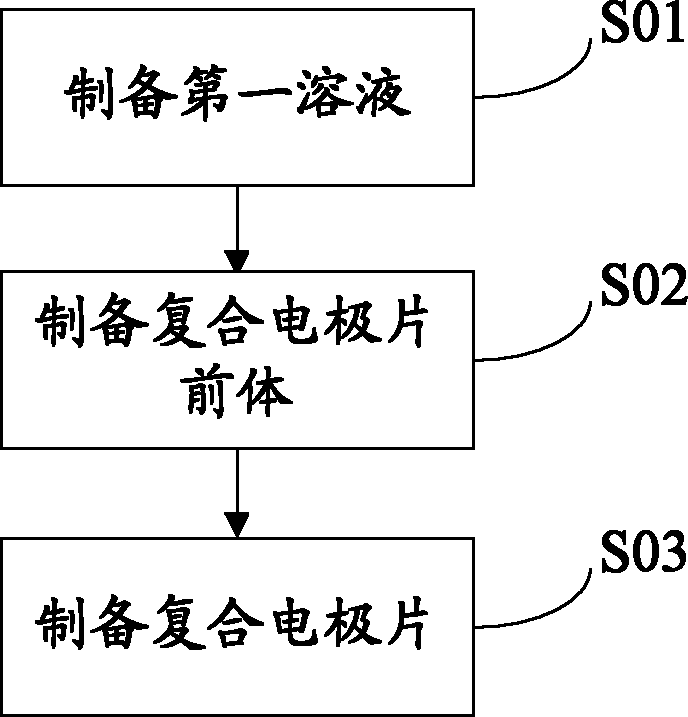

[0014] see figure 1 , figure 1 Show the flow chart of the preparation method of the composite electrode sheet according to the embodiment of the present invention, including the following steps:

[0015] Step S01, preparing the first solution

[0016] adding graphene oxide and carbon nanotubes with a weight ratio of 1 to 2:1 into an alcohol solvent, ultrasonically treating, and stirring to obtain a first solution;

[0017] Step S02, preparing a composite electrode sheet precursor

[0018] Adding a metal salt solution to the first solution, ultrasonically treating it to obtain a second solution, using the second solution as an electrolyte, and using a metal foil as an electrode, performing electrophoresis treatment to obtain a composite electrode sheet precursor;

[0019] Step S03, preparing a composite electrode sheet

[0020] The electrode sheet precursor is dried, put into a reducing solution, and reacted for 1 hour to 36 hours at a temperature of 80°C to 100°C, and the ...

Embodiment 1

[0036] The preparation method of the composite electrode sheet according to the embodiment of the present invention comprises the following steps:

[0037] Graphite oxide was prepared by the modified Hummers method:

[0038]Add 20g of 50 mesh graphite powder, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6h, wash until neutral, and dry. Add the dried sample to 460mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL of deionized water . After 15 minutes, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow. Suction filtration while hot, and then wash with 5L of 10% hydrochloric acid, suction filtration, Graphite oxide was obtained by vacuum drying at 50°C for 48 hours...

Embodiment 2

[0049] The preparation method of the composite electrode sheet according to the embodiment of the present invention comprises the following steps:

[0050] Graphite oxide was prepared by the modified Hummers method:

[0051] Add 20g of 50 mesh graphite powder, 10g of potassium persulfate and 10g of phosphorus pentoxide into concentrated sulfuric acid at 80°C, stir evenly, cool for more than 6h, wash until neutral, and dry. Add the dried sample to 460mL of concentrated sulfuric acid at 0°C, then add 60g of potassium permanganate, keep the temperature of the mixture below 20°C, then keep it in an oil bath at 35°C for 2 hours, then slowly add 920mL of deionized water . After 15 minutes, add 2.8L of deionized water (which contains 50mL of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow. Suction filtration while hot, and then wash with 5L of 10% hydrochloric acid, suction filtration, Graphite oxide was obtained by vacuum drying at 50°C for 48 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com