Nano doping structure and preparation method thereof

A nanostructure and nanotechnology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as inability to dope nanomaterials, difficulty in doping measurement, and shape change of nanomaterials, to achieve Wide range of applications, precise control of doping metering, and precise control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

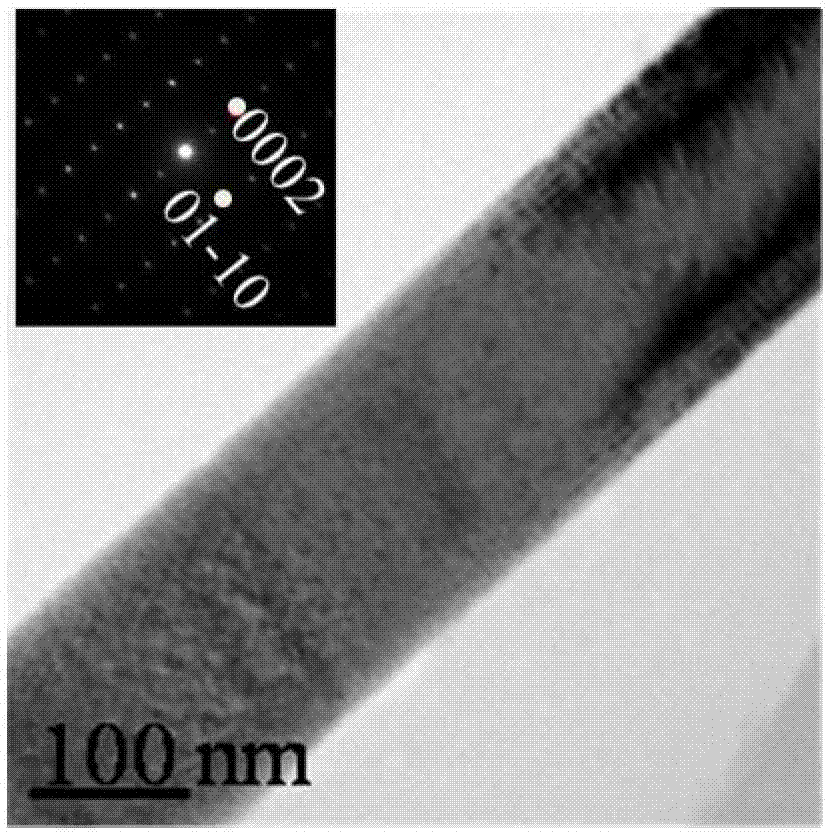

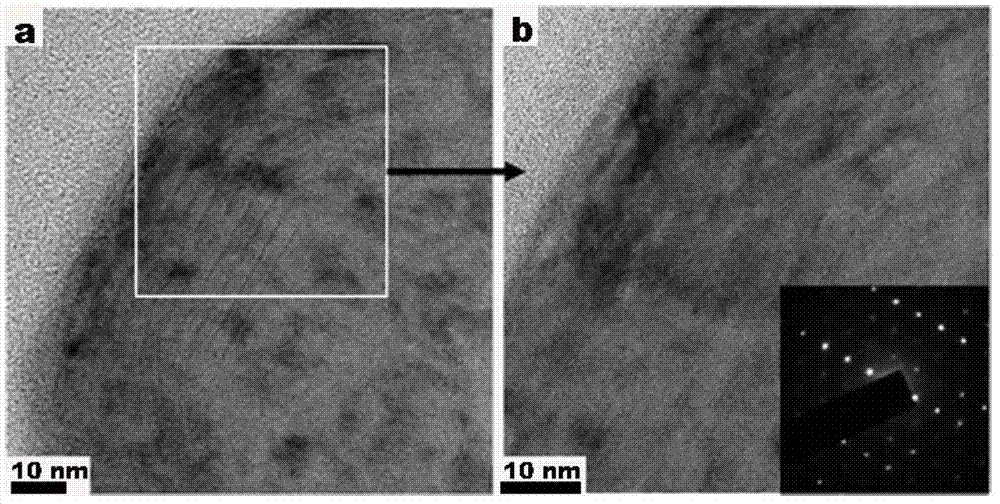

[0028] The invention provides a method for doping nanometer materials by atomic layer deposition technology. The atomic layer deposition system consists of a reaction chamber, a vacuum system, a heating system and a precursor control system. Taking Al-doped ZnO nanowires as an example to illustrate the specific implementation method.

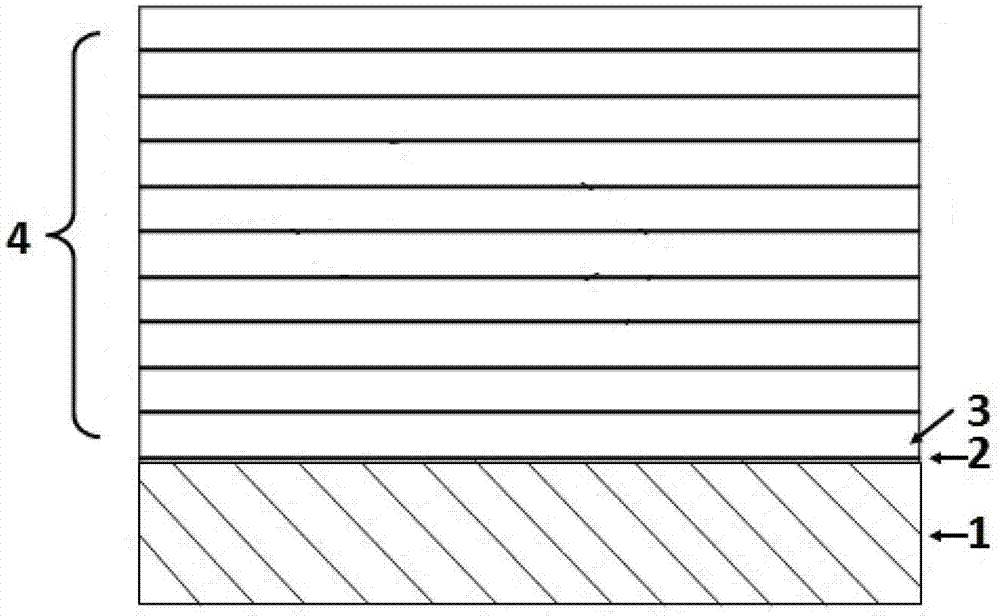

[0029] see figure 1 , the specific process is:

[0030] 1) Put the pre-grown ZnO nanowires (substrate) into the reaction chamber of the atomic layer deposition system, evacuate to the ultimate vacuum, and then pass the flushing inert gas N 2 , keep the background air pressure at 260-300 mTorr, and the reaction chamber temperature at 150°C;

[0031] 2) First deposit a cycle of Al on the nanowire substrate 2 o 3 , In the reaction chamber of the atomic layer deposition system, high-purity nitrogen is used as the carrier gas and flushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com