Phosphor glass coating for optical wavelength conversion and white light emitting device

A fluorescent glass and wavelength conversion technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of fluorescent wavelength drift, device operating temperature increase, affecting device light efficiency, etc., to avoid the deterioration of silica gel or resin. Yellow and reflective, good conversion efficiency, the effect of alleviating heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the present invention: (1) Mix the powder of glass B with the powder of phosphor C, organic solvent and binder at a mass ratio of 100:1-100:150 to form a uniform paste; liquid alcohol , ethers, ketones, esters, and hydrocarbons. Binders are solvent-soluble polymers (such as water-soluble polyvinyl alcohol, carboxycellulose), acrylic resins, styrene resins, butyral resins, ethyl cellulose, and the like.

[0047] (2) Apply the paste evenly on the glass substrate A, and dry the glass substrate A coated with the paste to completely evaporate the organic solvent;

[0048] (3) Sintering the dried glass substrate A coated with the paste, and obtaining a glass B coating layer containing phosphors on the surface of the glass substrate A.

[0049] In step (1), the mass ratio of the organic solvent to the binder is 10:1-1:1, and the organic solvent is one of phthalate and terpineol or a mixture of two of them in any proportion; The binder is one of acry...

Embodiment 1

[0053] The present invention will be described in detail below with reference to the accompanying drawings.

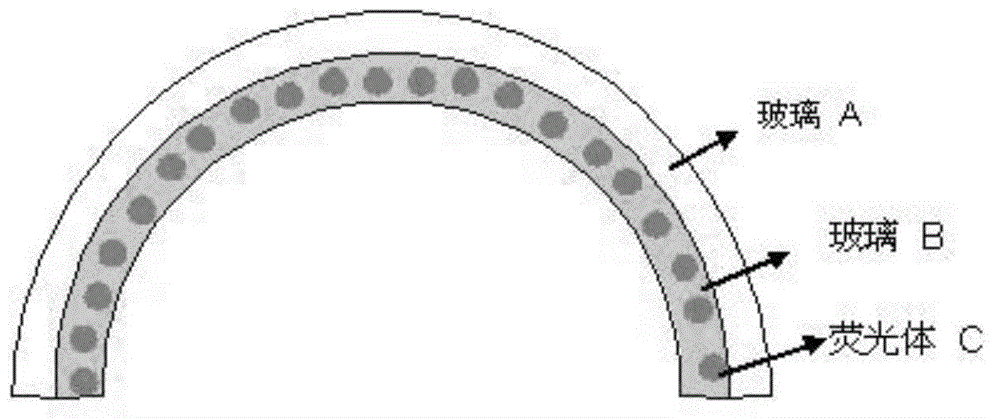

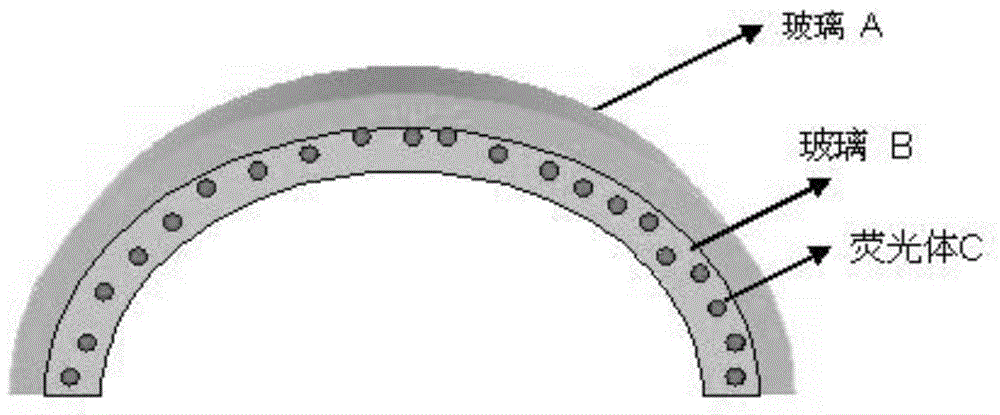

[0054] to attach figure 1 A method of manufacturing a phosphor-containing glass-coated glass substrate will now be described in detail.

[0055] As one of the specific examples, figure 1 The medium glass substrate A is ordinary soda lime glass, the surface is a part of a spherical surface, the thickness is 1 mm, and the glass transition temperature is 570 o C, softening temperature 620 o c.

[0056] As one of the specific examples, figure 1 Medium glass B is a low-melting phosphate glass, and its components include P 2 o 5 : 41%, ZnO: 34%, B 2 o 3 : 19%, (Li 2 O 3% + Na 2 O 1.5% + K 2 O 1.5%): 6%. Glass transition temperature 480 o C, the softening temperature is 526 o C;

[0057] Phosphor C is YAG yellow phosphor, and its particle size distribution is d 50 to 10 microns.

[0058] The particle size distribution of glass B powder is d 50 =15 micron...

Embodiment 2

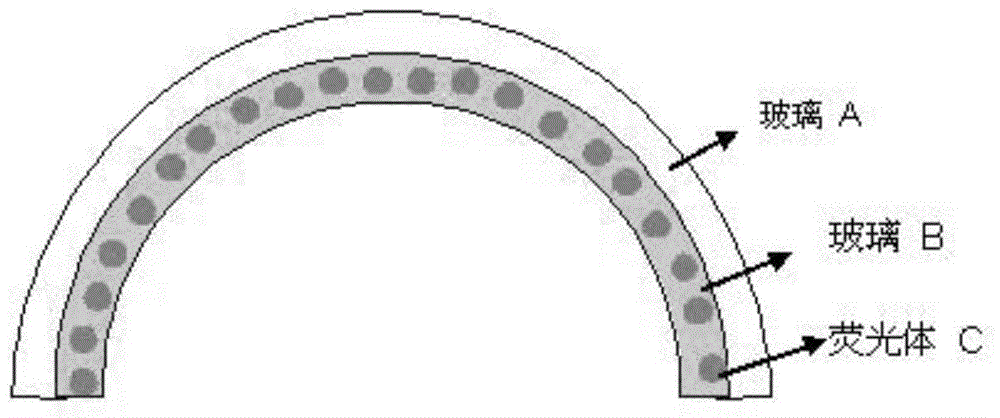

[0067] The difference between this embodiment and embodiment 1 lies in the use of image 3 The double-layer phosphor-containing glass coating structure shown, wherein:

[0068] 1 is containing (Sr,Ca)S:Eu 2+ Glass coating of red phosphor, 2 is glass coating containing YAG yellow phosphor. The composition of Glass B for the two coats is the same as in Example 1. The particle size distribution of the two phosphor particles is d 50 =15 microns.

[0069] The two-layer glass coating containing the phosphor in this example is transparent after sintering, with a smooth surface and no warped edges.

[0070] Using a blue light chip grown on a 1W SiC substrate, the blue light emitted by the blue light chip irradiates the glass A substrate with the glass B coating containing phosphors, and a bright white light (84 lm / W) is obtained.

[0071] In this embodiment, the glass substrate A can also be cylindrical, as shown in the schematic diagram Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com