A fluorescent resin component and its manufacturing method

A technology of fluorescent resin and manufacturing method, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., which can solve the problems of fluorescent powder emission wavelength shift, poor scattering of blue light chips, and affecting the light efficiency of devices, so as to keep the light effect from degrading , Avoid the effect of device light efficiency drop and low ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

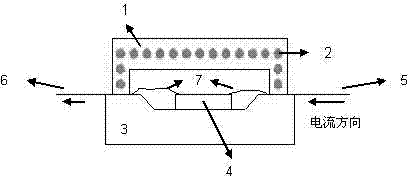

[0034] Example 1: by figure 1 A method for producing a phosphor-containing resin will be described in detail. The resin material is optical grade acrylic (PMMA VH001) with a particle size of 5 microns. The phosphor is YAG yellow phosphor with a particle size of 5 microns. The ultraviolet absorber is UV-327, and the antioxidant is antioxidant 1010.

[0035] The volume ratio of acrylic to phosphor is 100:15%; the mass ratio of acrylic to ultraviolet absorber UV-327 is 100:0.25; the mass ratio of acrylic to antioxidant 1010 is 100:0.25.

[0036] After fully mixing phosphor powder and acrylic powder, at 160 o C is molded into a plate with a thickness of 0.4 mm, and cooled to room temperature to obtain a fluorescent resin. The obtained fluorescent resin has a smooth surface without burrs.

[0037] Afterwards, the obtained fluorescent resin was again heated at 130 o The C-molded overmolding is a hollow cube with a wall thickness of 0.4 mm.

[0038] Using a blue light chip...

Embodiment 2

[0039] Embodiment 2: the temperature of first injection molding is at 190 o C, secondary molding temperature at 150 o c.

Embodiment 3

[0040] Example 3: The resin material is not limited, such as optical grade polycarbonate PC. Granulate before injection molding, different resins can adopt different injection molding process conditions.

[0041] Using a blue light chip grown on a 1W SiC substrate, the blue light emitted by the blue light chip irradiates the above-mentioned fluorescent resin inside to obtain bright white light (118-135 lm / W).

[0042] In the embodiment, the resin can be acrylic (PMMA), PMMA alloy resin, polycarbonate, PC alloy resin, epoxy, styrene-butadiene, phenylsulfone resin, CR-39, MS, NAS, polyurethane optical resin, nylon or PC Good results can be obtained with reinforced PMMA or MS resins.

[0043] According to different requirements, the volume ratio of resin to phosphor is generally not limited, such as 100:1~100:150, generally 100:20~100:50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com