Optical wavelength conversion component, its preparation method and white light emitting device

A technology of wavelength conversion and components, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve the problems of reduced light efficiency of devices, deterioration of phosphor luminescence characteristics, etc., and achieves enhanced heat dissipation effect, ease of heat dissipation problems, and low ambient temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

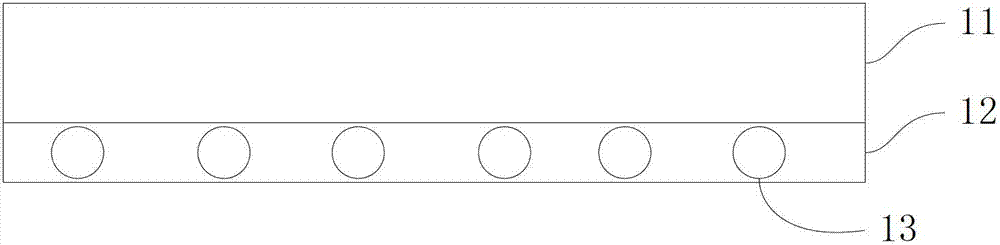

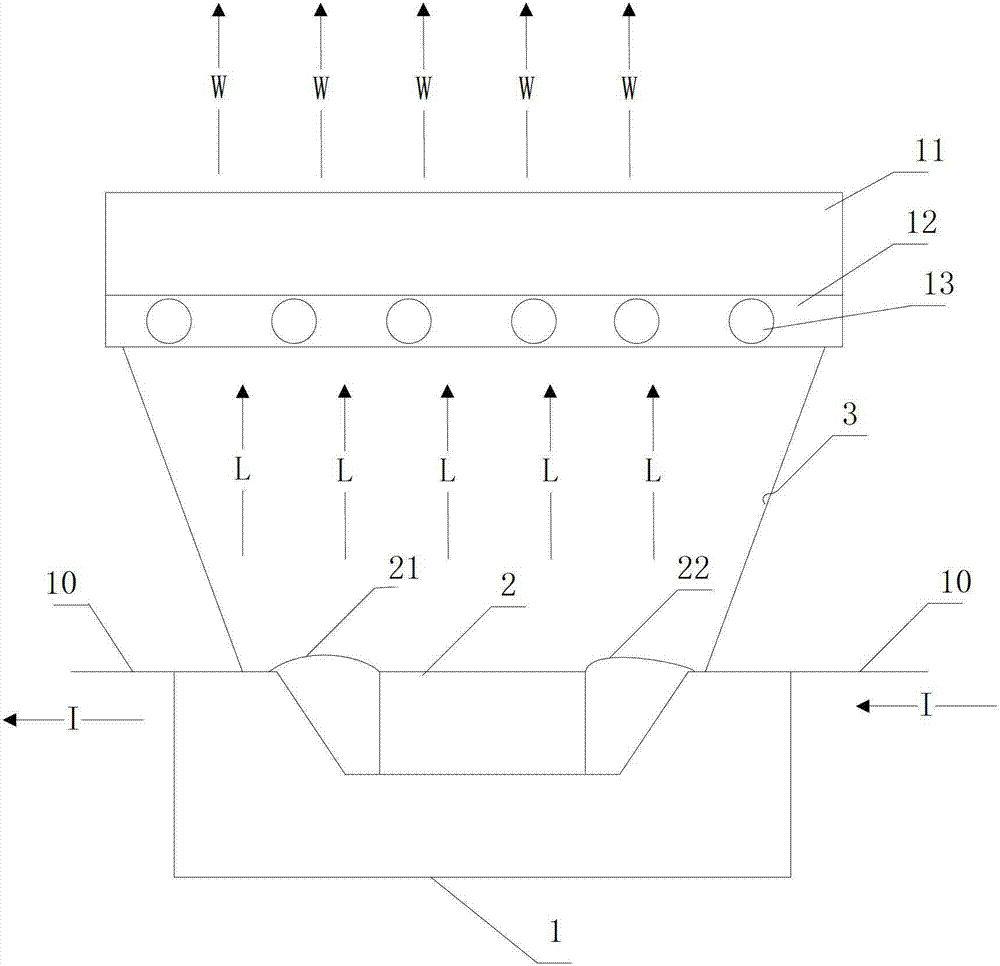

[0023] figure 1 It is a schematic structural diagram of an optical wavelength conversion component according to an embodiment of the present invention. The optical wavelength conversion component includes a resin substrate 11 and a mixed coating 12 containing resin and phosphor powder 13 on the surface of the resin substrate.

[0024] The material of the resin substrate 11 is PMMA, PMMA alloy resin, polycarbonate, PC alloy resin, epoxy, styrene-butadiene, phenylsulfone resin, CR-39, MS, NAS, polyurethane optical resin, nylon or PC reinforced PMMA or MS resin; resin powder material is PMMA, PMMA alloy resin, polycarbonate, PC alloy resin, styrene-butadiene, phenylsulfone resin, CR-39, MS, NAS, nylon or PC reinforced PMMA or MS resin; resin The substrate and the resin powder may be of the same kind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com