Constant-current light emitting diode (LED) power supply with temperature compensation function

A LED power supply and temperature compensation technology, which is applied in the direction of electric light source, light source, lamp circuit layout, etc., can solve the problems of absence, damage, and low LED life, and achieve the effects of reducing heat generation, prolonging service life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

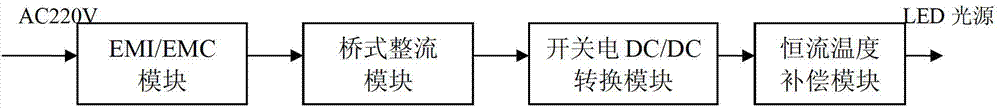

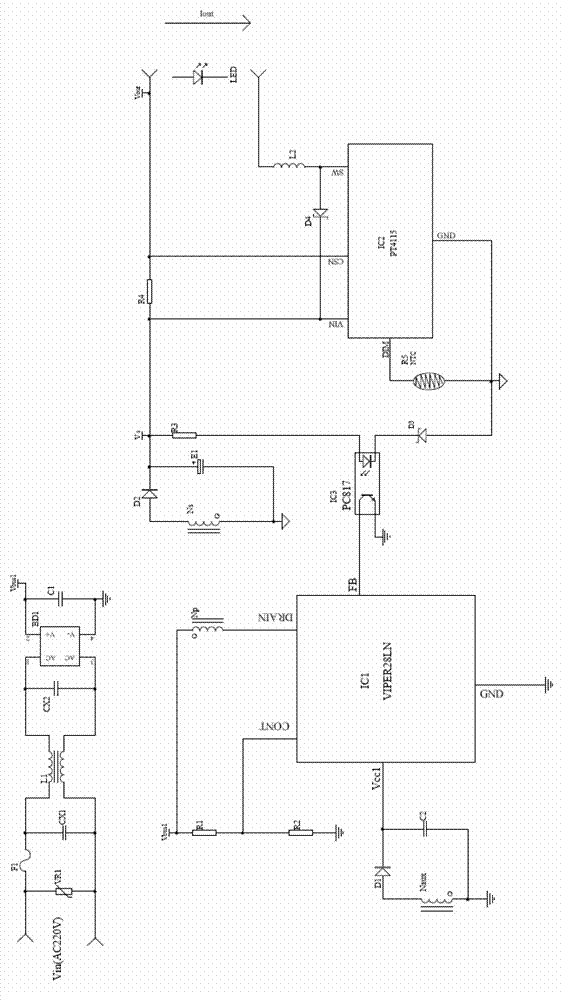

[0018] The present invention will be further described below in conjunction with drawings and embodiments. The invention is used for AC 220V input, LED lighting with temperature compensation and constant current output, including the following parts:

[0019] 1. EMI / EMC circuit. Prevent electromagnetic interference between the outside world and the controller.

[0020] 2. Bridge rectification. Used to convert AC input to DC Vbus1.

[0021] 3. Switching power converter IC1, the model can be VIPER28 and peripheral circuits.

[0022] 4. Transformer. It is used to change the high voltage DC Vbus1 into a low voltage DC Vs.

[0023] 5. Voltage limiting control circuit. Used to limit the DC voltage Vs within a certain range.

[0024] 6. Constant current chip IC2, the model can be PT4115. Make the output constant current with temperature compensation at the same time.

[0025] Such as figure 1 Shown: According to the division of functional modules, the present invention incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com