Double-emitting layer hemispherical shell-shaped organic electroluminescent device and its preparation method

A hemispherical shell, dual emission technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of annihilation and hinder the application of phosphorescent OLED devices, reduce the starting voltage, widen the collision recombination area, reduce the Annihilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

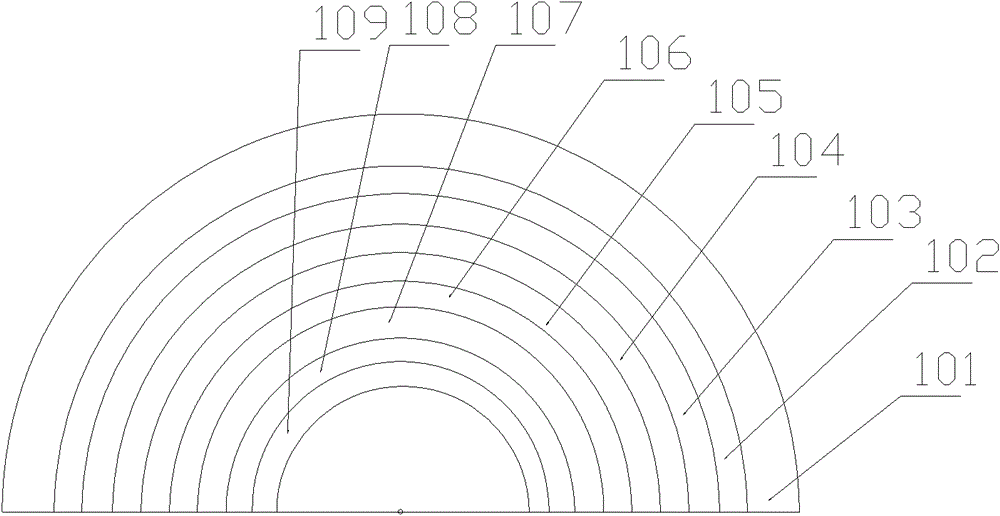

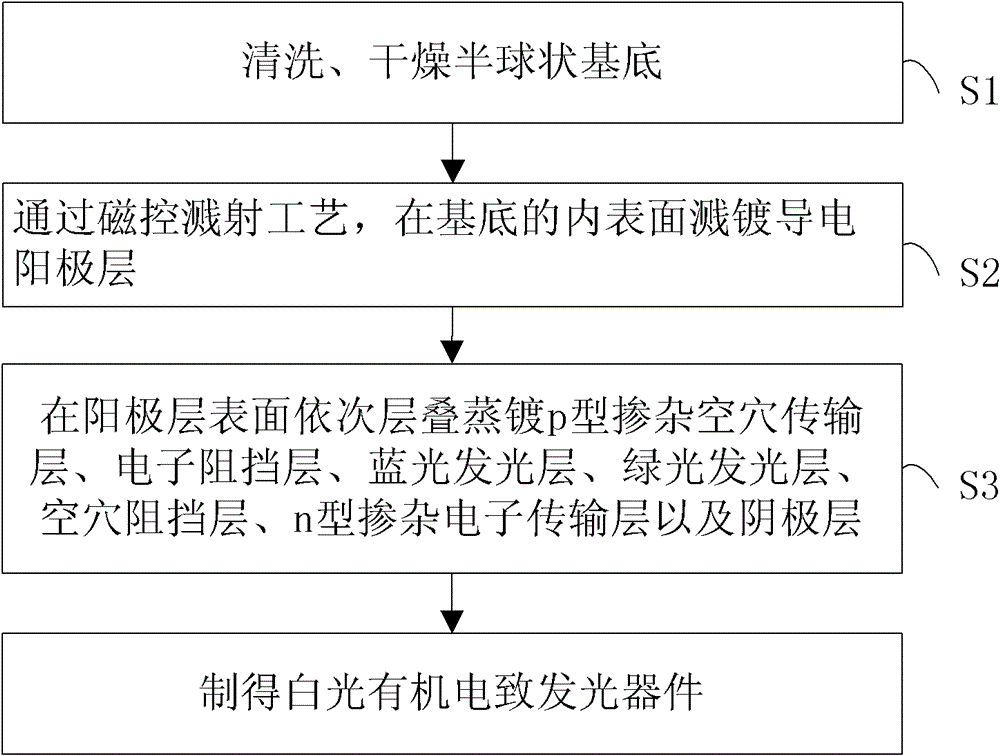

[0047] The preparation method of the above-mentioned double-emitting layer hemispherical shell-shaped organic electroluminescent device, such as figure 2 shown, including the following steps:

[0048] S1. The hemispherical substrate (eg, glass) is ultrasonically cleaned with purified water, acetone, ethanol, etc. for 15 minutes in sequence, and dried after cleaning;

[0049] S2. Using a magnetron sputtering process, the hemispherical shell-shaped substrate is placed in a vacuum chamber of a magnetron sputtering device, and an anode layer is sputtered on the inner surface of the hemispherical shell-shaped substrate; the hemispherical shell-shaped anode substrate is obtained, Subsequently, the anode layer was treated with oxygen plasma with a power of 10W for 15min;

[0050] S3. Put the hemispherical shell-shaped anode substrate into the organic vacuum chamber of the evaporation equipment, and sequentially evaporate the p-type doped hole transport layer, light-emitting layer, ...

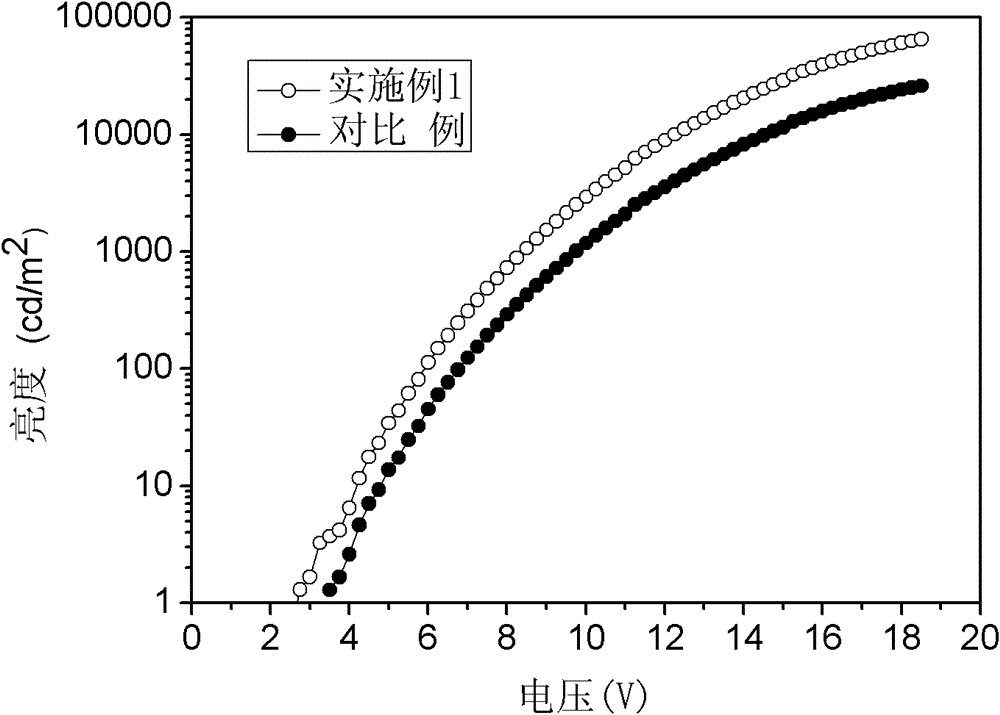

Embodiment 1

[0056] The structure of the hemispherical organic electroluminescence device of the present embodiment is: glass / ITO / m-MTDATA:F4-TCNQ / TAPC / (TCTA:TPBi):Firpic:Ir(MDQ) 2 (acac) / (TCTA:TPBi):Ir(ppy) 3 :Ir(MDQ) 2 (acac) / Bphen / Bphen:Cs 2 CO 3 / Mg:Ag.

[0057] The preparation steps of the hemispherical shell-shaped organic electroluminescent device with double emission layers in this embodiment are as follows:

[0058] 1. Clean the hemispherical glass substrate with an inner diameter of 5mm and a thickness of 2mm with pure water, acetone, ethanol, etc. for 15 minutes, and then dry it;

[0059] 2. Put the hemispherical glass substrate into the organic vacuum chamber of the magnetron sputtering equipment, sputter a layer of 150nm thick ITO anode layer; then spin-coat the glass coated with the ITO anode layer with photoresist, expose and develop , Aqua regia etching, etch into the required pattern and size, then clean the etched conductive glass, and then use pure water, acetone, e...

Embodiment 2

[0064] The structure of the hemispherical shell-shaped organic electroluminescent device with double emission layers of the present embodiment is:

[0065] Glass / FTO / TPD:TCNQ / TPD / (TCTA:TPBi):FIr6:Ir(MDQ) 2 (acac) / (TCTA:TPBi):Ir(ppy) 3 :Ir(MDQ) 2 (acac) / PBD / PBD:LiF / Ag.

[0066] The preparation steps of the hemispherical shell-shaped organic electroluminescent device with double emission layers in this embodiment are as follows:

[0067] 1. The hemispherical glass substrate with an inner diameter of 5 mm and a thickness of 4 mm was ultrasonically cleaned with purified water, acetone, ethanol, etc. for 15 minutes, cleaned and dried;

[0068] 2. Put the hemispherical glass substrate into the organic vacuum chamber of the magnetron sputtering equipment, sputter a layer of FTO anode layer with a thickness of 180nm; then spin-coat the glass coated with the FTO anode layer with photoresist, expose and develop , Aqua regia etching, etch into the required pattern and size, then clea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com