Determination method for trace impurity elements such as sodium, magnesium, calcium, iron and lead in high-purity boric acid

A technology of high-purity boric acid and determination method, which is applied in the preparation of test samples, measurement of color/spectral properties, thermal excitation analysis, etc. The effect of eliminating matrix differences and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

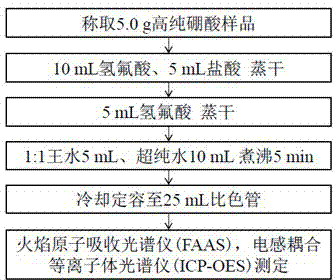

[0040] Such as figure 1 Shown, the assay method of trace impurity element sodium, magnesium, calcium, iron, lead in the high-purity boric acid provided by the invention, its steps are as follows:

[0041] Accurately weigh 5.000 g of the high-purity boric acid sample to be tested, pour it into a polytetrafluoroethylene (PTFE) crucible, add 10 mL of hydrofluoric acid (HF) and 5 mL of hydrochloric acid (HCl), and steam on a temperature-controlled electric heating plate at 200 °C. Dry;

[0042] Add 5 mL HF and evaporate to dryness again to remove the boric acid matrix as much as possible;

[0043] Add 5 mL of 1:1 (v / v) newly prepared aqua regia and 10 mL of ultrapure water into a polytetrafluoroethylene (PTFE) crucible, heat to boiling on an electric heating plate, take it off after 5 min, and let it cool naturally Dilute to a 25 mL stoppered colorimetric tube with ultrapure water, shake well to be tested;

[0044] The working conditions of the selected instruments are as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com