High-strength high-toughness epoxy resin adhesive and preparation method thereof

A tough epoxy resin and epoxy resin technology, which is applied in the field of epoxy adhesive preparation, can solve the problem that the technical requirements of wind turbine blades cannot be met, the technical requirements of wind turbine blades cannot be met, and the material strength and modulus decrease, etc. problem, to achieve the effect of good toughness, high strength and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

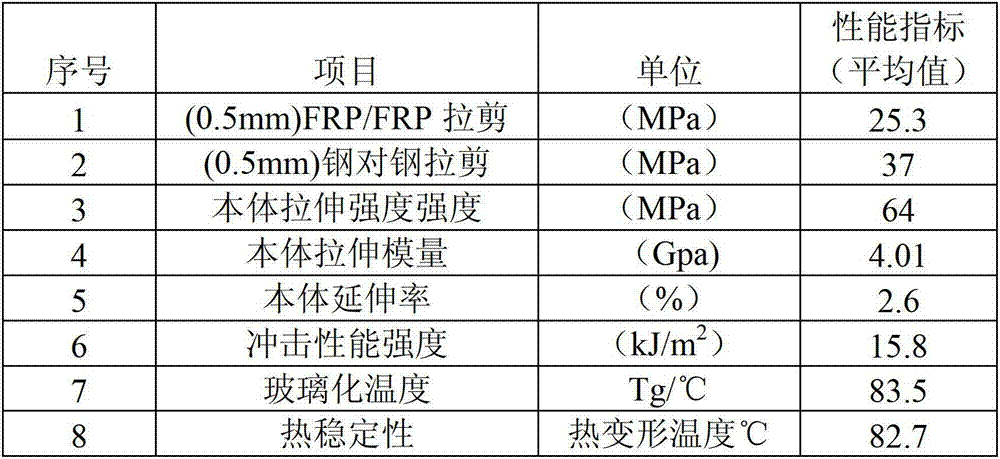

Examples

Embodiment 1

[0023] A high-strength and high-toughness epoxy resin adhesive, the adhesive is composed of two components A and B, wherein, in parts by weight,

[0024] Component A is composed of the following substances: bisphenol A epoxy resin: 90 parts; bisphenol F epoxy resin: 12 parts; ethylene glycol glycidyl ether: 10 parts; KH560: 2.5 parts; glass fiber: 9 parts; White carbon black: 12 parts; Nano zinc borate: 3 parts;

[0025] Component B is composed of the following materials: linear polyetheramine D230: 8 parts; linear polyetheramine D400: 2 parts; T-type polyetheramine T403: 25 parts; T-type polyetheramine T5000: 3 parts; DDS: 1 part; KH550: 2.3 parts; DMP-30: 2.5 parts; glass fiber: 8 parts; fumed silica: 5 parts; yellow pigment: 0.02 parts;

[0026] Mix the two components A and B according to the mass ratio of 100:40, apply it on the bonding part, cure at 80°C for 2 hours, and cure at 120°C for 2 hours.

Embodiment 2

[0028] A high-strength and high-toughness epoxy resin adhesive, the adhesive is composed of two components A and B, wherein, in parts by weight,

[0029] Component A is composed of the following materials: bisphenol A epoxy resin: 75 parts; bisphenol F epoxy resin 25 parts; polypropylene glycol glycidyl ether: 13 parts; KH560: 2 parts; glass fiber: 11 parts; fumed white carbon Black: 15 parts; Nano calcium carbonate 1 part; Green pigment: 0.01 part;

[0030] Component B is composed of the following materials: linear polyetheramine D230: 6 parts; linear polyetheramine D400: 2 parts; T-type polyetheramine T403: 21 parts; T-type polyetheramine T5000: 4 parts; IPDA: 7 parts; DDM: 1 part; KH550: 2.1 parts; DMP-30: 2 parts; glass fiber: 7 parts; fumed silica: 6 parts; blue pigment: 0.02 parts;

[0031] Mix the two components of A and B according to the mass ratio of 100:42, apply it on the bonding part, and cure it at 80°C for 2 hours, and at 120°C for 2 hours.

Embodiment 3

[0033] A high-strength and high-toughness epoxy resin adhesive, the adhesive is composed of two components A and B, wherein, in parts by weight,

[0034] Component A consists of the following substances: bisphenol A epoxy resin: 100 parts; hydrogenated bisphenol A epoxy resin: 3 parts; polypropylene glycol glycidyl ether: 8 parts; o-cresyl glycidyl ether: 5 parts; KH560: 3 parts; carbon fiber: 5 parts; fumed silica: 8 parts; silica fume: 2 parts; alumina: 1 part; red pigment: 0.03 parts;

[0035] Component B is composed of the following materials: linear polyetheramine D230: 6 parts; linear polyetheramine D400: 1 part; T-type polyetheramine T403: 20 parts; T-type polyetheramine T5000: 5 parts; IPDA: 5 parts; DDM: 1 part; KH550: 2 parts; 2-methylimidazole: 1.5 parts; carbon fiber: 3 parts; fumed silica: 3 parts; yellow pigment: 0.01 parts;

[0036] Mix the two components of A and B according to the mass ratio of 100:43, apply it on the bonding part, cure at 80°C for 2 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com