Welding method and glue piece for welding and application of glue piece

A film and adhesive layer technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of inconvenient welding, etc., achieve good welding effect, prevent welding position deviation, and achieve good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

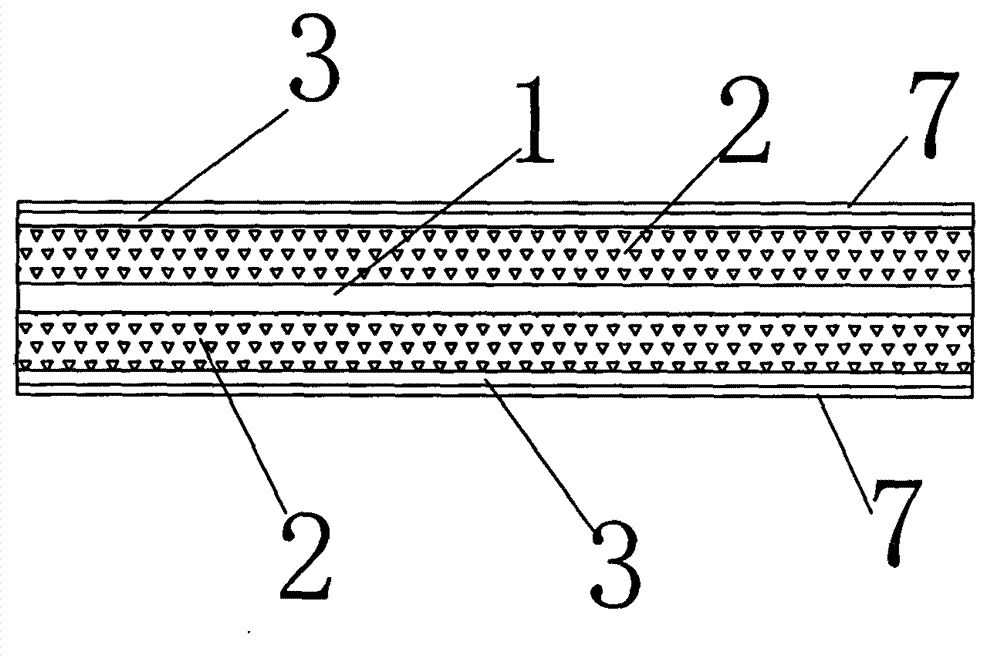

[0035] refer to figure 1 and Figure 4 Shown: a film for welding, including a metal layer 1, a solder layer 2, and a viscous adhesive layer 3, the outer surface of the metal layer 1 is covered with a solder layer 2, and the outer surface of the solder layer 2 is glued with welding activity sticky glue layer3.

[0036] The welding film 5 is a strip-shaped rubber strip, the length is not limited, and the upper and lower sides of the welding film 5 are sticky.

[0037] The metal layer 1 is made of metal copper.

[0038] The welding film 5 is wound on a fixing base 6 .

Embodiment 2

[0040] refer to figure 1 and image 3 Shown: A welding method comprising the following steps:

[0041] S1. Making the welding film 5: using a cutting device to cut the metal layer 1 of the required size; coating or plating the surface of the metal layer 1 with a solder layer 2; then coating or plating the surface of the solder layer 2 with soldering properties The active adhesive adhesive layer 3 is finally pasted with a release paper 7 on the outer surface of the adhesive adhesive layer 3; the welding film 5 is a laminar film.

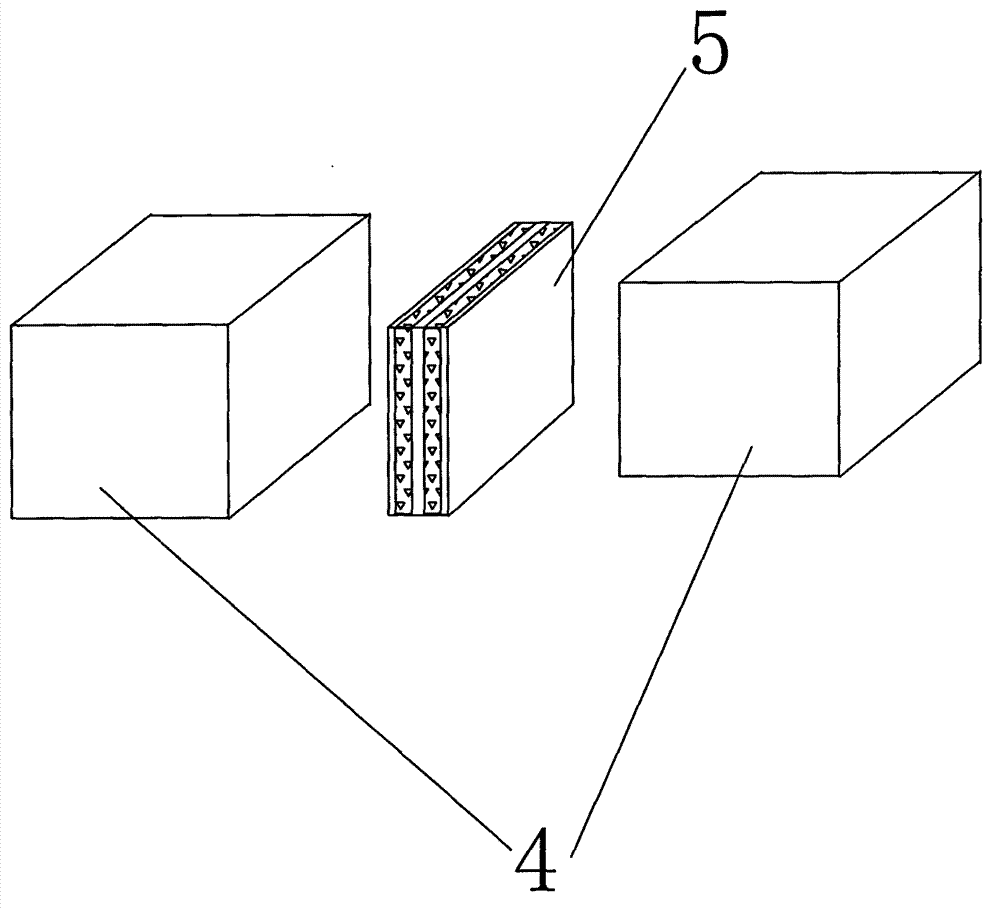

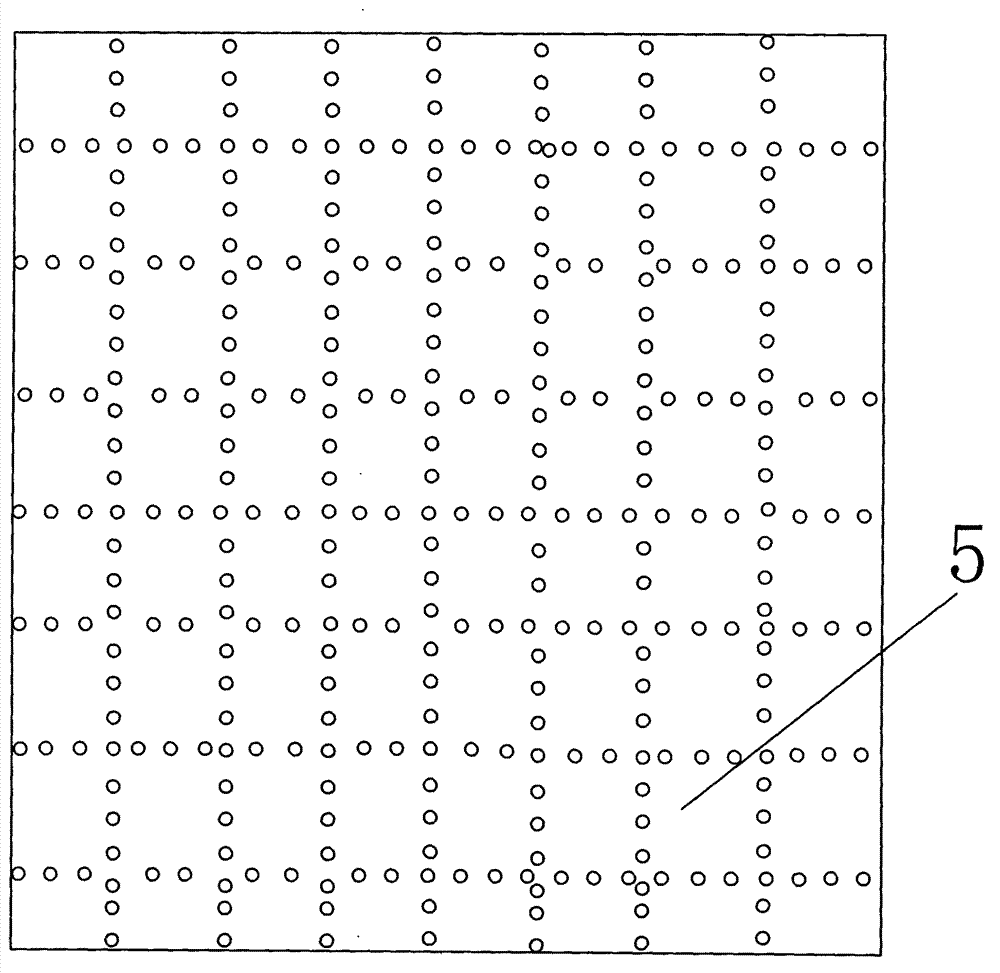

[0042] S2. Punch the welding film 5 into a row of holes in units of 1cm*1cm. The film can be broken or divided into small pieces according to the size of the weldment. The upper and lower sides of the welding film 5 are sticky, and it is sandwiched between two welding metal 4 in the space between, bonded and fixed;

[0043] S3. Melt the welding film 5 at 115°C-1250°C until it is fixed by welding.

Embodiment 3

[0045] Refer to Figure l and figure 2 Shown: the application of the welding film 5 in the fan welding process in the main computer case:

[0046] The welding film includes a metal layer 1 , a solder layer 2 , and a viscous adhesive layer 3 , the metal layer 1 is attached with the solder layer 2 , and the solder layer 2 is adhered with the viscous adhesive layer 3 . The welding film 5 is a strip-shaped rubber strip, the length is not limited, and the upper and lower sides of the welding film 5 are sticky. The metal layer 1 is made of metal copper. The welding film 5 has a width of 5 cm and a thickness of 15 mm. The welding film 5 is wound on a fixing base 6 .

[0047] The operation of welding the fan and the computer case with the welding film of the above structure:

[0048] First, use a cutting device to cut off the required length of welding film 5 from the fixed seat, and its size is similar to the size of the fan welding surface; then, clamp the welding film 5 in the ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com