Full-automatic descaling multi-effect evaporator

A multi-effect evaporator, fully automatic technology, applied in the direction of multi-effect evaporator, standpipe evaporator, evaporator accessories, etc., can solve the problems of reducing heat transfer efficiency, increasing energy consumption and industrial investment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

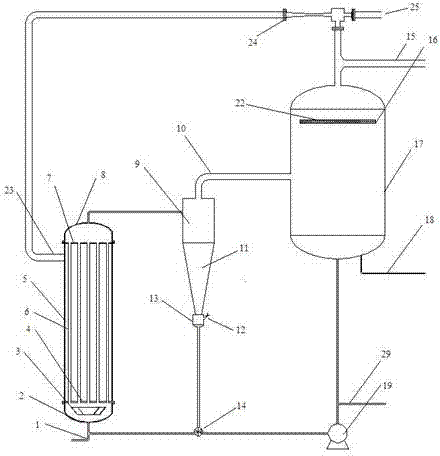

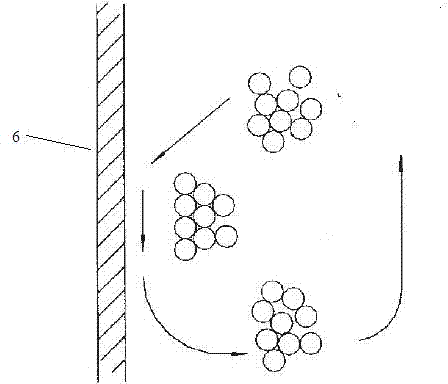

[0022] Such as figure 1 As shown, the liquid inlet 1 is installed at the bottom of the heater 5 and is connected with the lower tube box 2, and the particle distributor 3 is installed at about 100 mm above the lower tube box 2. This position is most beneficial for the particle-liquid mixture to have enough The distance between the particles enters the particle distributor, so that the particles are evenly distributed, and the fluid velocity is also reasonably divided, so that it enters the tube array 6 installed between the upper tube sheet 7 and the lower tube sheet 4 at a roughly uniform speed. After the fluid in the liquid inlet 1 passes through the particle distributor 3, the fluid with a faster flow rate in the middle is evenly dispersed into the surrounding tubes. The lower tube box 2 and the lower tube plate 4 are connected by flanges, and the lower tube plate 4 and the upper tube plate 7 Weld the tubes 6 in the middle, and it is better to polish the inside of the tubes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com