Colored resin composition

A resin composition, color filter technology, applied in cameras, instruments, electrical components, etc., can solve the problems of inability to form blue pixels, not yet practical, and achieve excellent heat resistance and contrast, high reliability, and high reliability. high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0144] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. It should be noted that, in the following examples, unless otherwise specified, parts represent parts by mass, and % represents mass %. In addition, the maximum absorption wavelength was measured using the ultraviolet spectrophotometer UV-2450 (made by Shimadzu Corporation).

Synthetic example 1

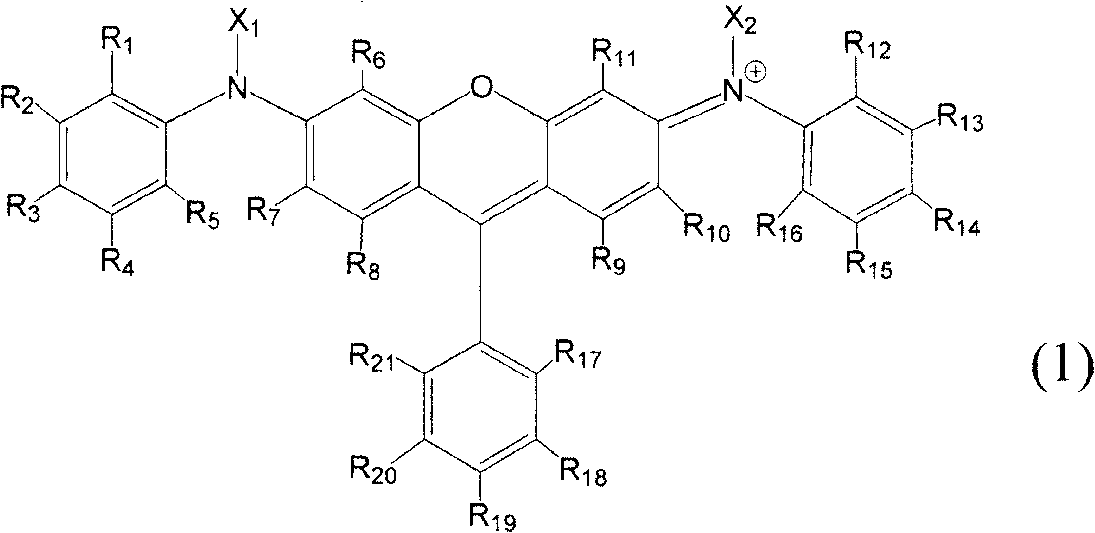

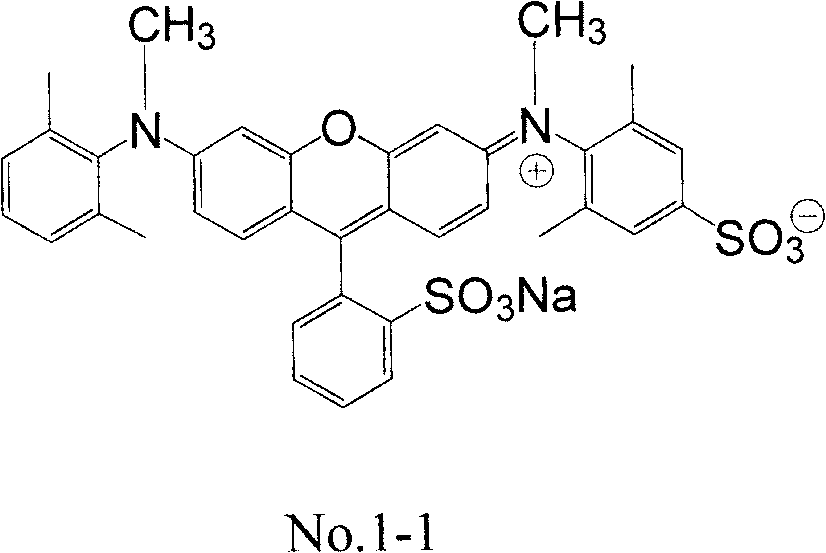

[0145] Synthesis example 1 (synthesis of a pigment mainly composed of compound No.1-1: dye of formula (1))

[0146] 5.8 parts of Acid Red 289 (manufactured by Tokyo Chemical Industry Co., Ltd.) and 82.5 parts of dry dimethyl sulfoxide were put into a 300 ml four-necked flask, and stirred at normal temperature. 1.7 parts of oily sodium hydride (manufactured by Wako Pure Chemical Industries, Ltd.) was added thereto, stirred at room temperature for 1.5 hours, then, the reaction solution was cooled in an ice bath, and 75 parts of methyl iodide (manufactured by Tokyo Chemical Industry Co., Ltd.) were added dropwise. ), stirred at room temperature for 20 hours. After pouring the obtained reaction liquid into the mixed aqueous solution of 750 parts of water and 50 parts of 35% hydrochloric acid, 35% hydrochloric acid was added so that pH may become 0.3. The volume after addition of hydrochloric acid was 1000 ml. 200 parts of sodium chloride was added thereto, and the precipitated c...

Synthetic example 2

[0149] Synthesis example 2 (synthesis of a pigment mainly composed of compound No.1-2: dye of formula (1))

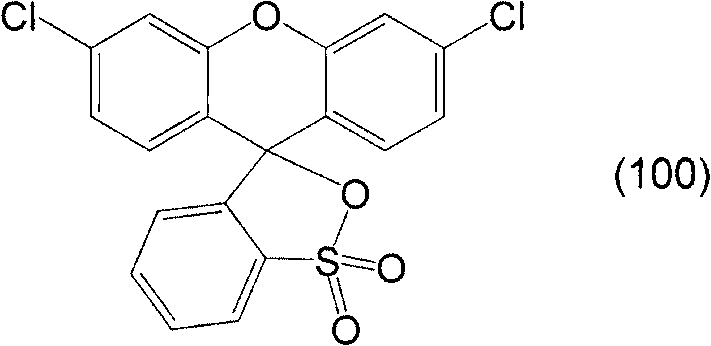

[0150] 4.1 parts of a sulfolane compound of the following formula (100), 312 parts of methanol, and 10.7 parts of N-methylaniline were charged into a 500 ml four-necked flask, and refluxed for 30 hours. The reaction solution was filtered at 60°C to remove insoluble components, and then the solvent was removed under reduced pressure until the reaction solution reached about 70 ml, and poured into 200 parts of 6% hydrochloric acid. Then, 600 parts of water were added, and after stirring at room temperature for 30 minutes, the wet cake was filtered off. This wet cake was suspended in 100 parts of water, stirred at 60°C for 2 hours, filtered again, washed with hot water at 60°C, and dried to obtain 2.5 parts of the following compound No.1 - 2 is the pigment for color filters of the present invention whose main component is. The maximum absorption wavelength of this dye is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com