Method for recycling acidic copper-etching waste solution

A technology for the recovery of acidic etching waste liquid and waste liquid, which is applied in the field of the preparation of ferric chloride water purifier and the recovery, treatment and reuse of acidic copper etching waste liquid. It can solve the problems of complex production process and many types of raw materials, and achieve The effect of short production process, environmental protection and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] The production method of the present invention is aimed at PCB acidic etching waste liquid, is oxidative copper-containing mixed liquid, and main ion component is: Cu 2+ 、Cu + , CuCl n 2-n (n is a natural number), H + , Cl - , ClO - , ClO 3 - 、H 2 o 2 , where ionic copper (Cu 2+ 、Cu + or copper complex ions) with a mass concentration of 8-10%, solution H + The concentration is 0.01-10.0mol / L.

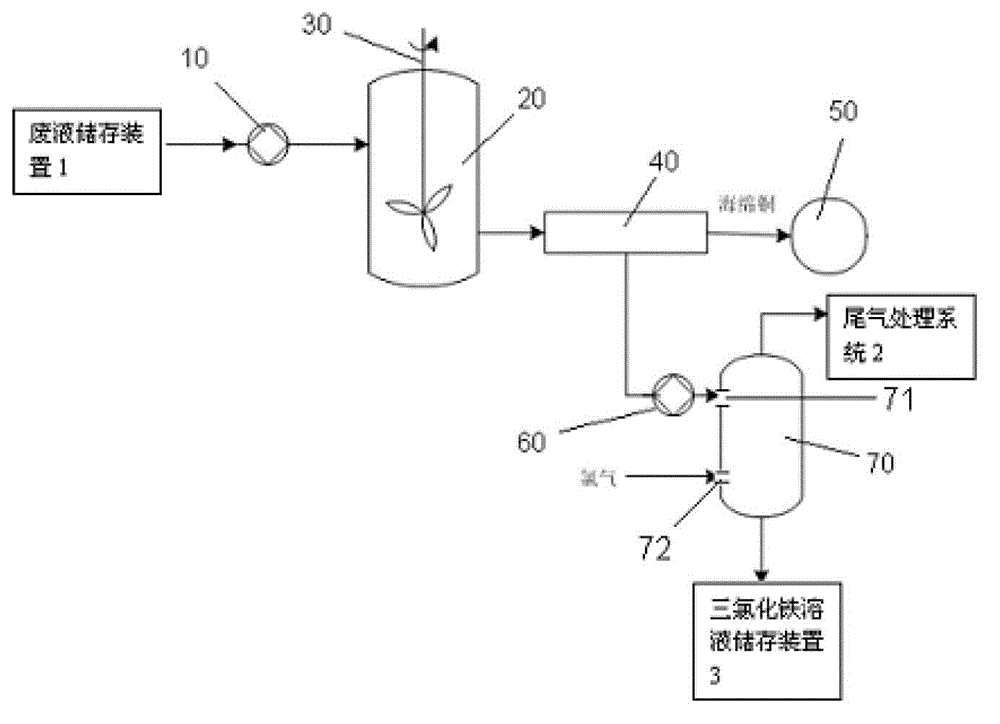

[0040] Such as figure 1 Shown is a schematic diagram of the process equipment system used in this embodiment. First use the first corrosion-resistant pump 10 to pump 10-20m 3 PCB acidic etching waste liquid is pumped into the reaction kettle 20 from the waste liquid storage device 1, at room temperature, under the stirring condition of the agitator 30, reduced iron is added to the reaction kettle 20, and the dosage of reduced iron is the theoretical requirement 110%, the iron replacement reaction time is 3-4 hours, during the reaction, the pH value of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com