Method for improving cavitation erosion resistance of TC4 titanium alloy based on ion implantation surface modification

A technology of ion implantation and surface modification, which is used in ion implantation plating, vacuum evaporation plating, metal material coating process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

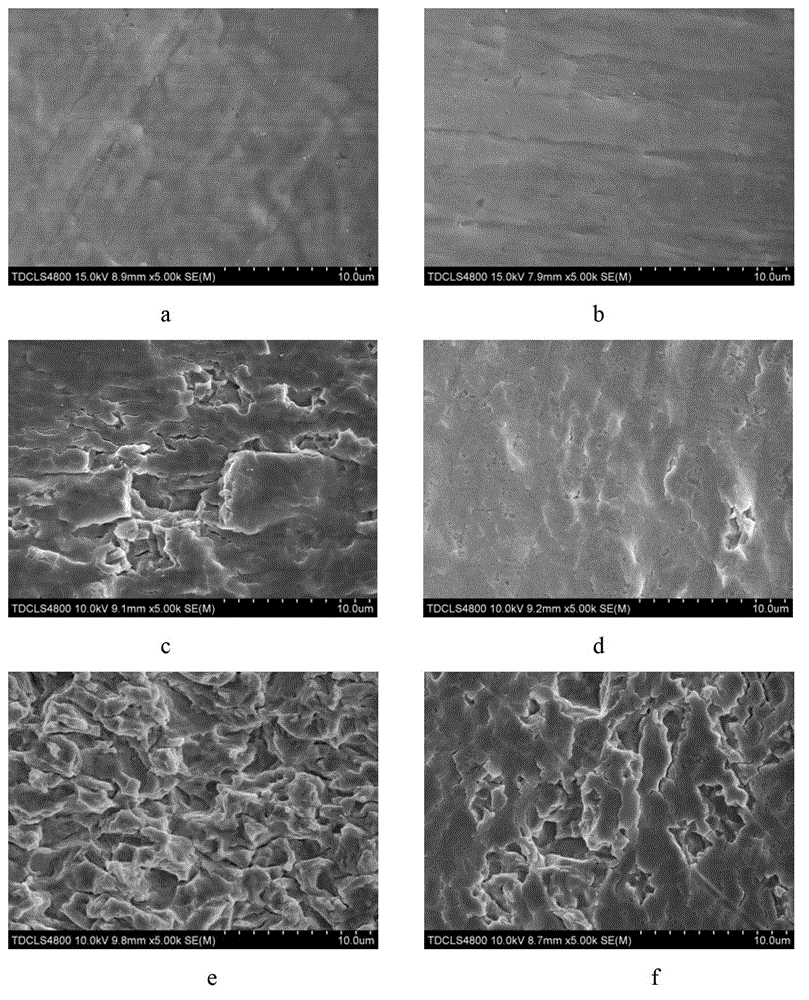

Image

Examples

Embodiment 1

[0014] Embodiment 1: A method for improving the cavitation corrosion resistance of TC4 titanium alloy, using ion implantation method to implant Nb element on the surface of TC4 titanium alloy.

[0015] The ion implantation of Nb element is carried out on the MEVVA source ion implanter, using high-purity niobium rod as the ion implantation source, and the implanted matrix is TC4 titanium alloy.

[0016] The process parameters used in the ion implantation process are:

[0017] The accelerating voltage during injection is: 70kv

[0018] Beam density: 4.8uA / cm 2

[0019] The air pressure in the target chamber is about: 1×10 -3 Pa

[0020] The dose of implanted Nb ions is: 5×10 16 ions / cm 2

[0021] The test of the cavitation performance is carried out according to the American ASTM standard. The experimental equipment is the ultrasonic vibration cavitation test machine produced by Ningbo Xinzhi Biotechnology Co., Ltd., and the sample to be tested is fixed on the variable ...

Embodiment 2

[0035] Embodiment 2: A method for improving the cavitation corrosion resistance of TC4 titanium alloy, using ion implantation method to implant Nb element on the surface of TC4 titanium alloy.

[0036] The ion implantation of Nb element is carried out on the MEVVA source ion implanter, using high-purity niobium rod as the ion implantation source, and the implanted matrix is TC4 titanium alloy.

[0037] The process parameters used in the ion implantation process are:

[0038] The accelerating voltage during injection is: 70kv

[0039] Beam density: 4.8uA / cm 2

[0040] The air pressure in the target chamber is about: 1×10- 3P a

[0041] The dose of implanted Nb ions is: 1×10 17 ions / cm 2

[0042] The test of the cavitation performance is carried out according to the American ASTM standard. The experimental equipment is the ultrasonic vibration cavitation test machine produced by Ningbo Xinzhi Biotechnology Co., Ltd., and the sample to be tested is fixed on the horn of t...

Embodiment 3

[0056] Embodiment 3: A method for improving the cavitation corrosion resistance of TC4 titanium alloy, using ion implantation method to implant Nb element on the surface of TC4 titanium alloy.

[0057] The ion implantation of Nb element is carried out on the MEVVA source ion implanter, using high-purity niobium rod as the ion implantation source, and the implanted matrix is TC4 titanium alloy.

[0058] The process parameters used in the ion implantation process are:

[0059] The accelerating voltage during injection is: 70kv

[0060] Beam density: 4.8uA / cm 2

[0061] The air pressure in the target chamber is about: 1×10 -3 Pa

[0062] The dose of implanted Nb ions is: 4×10 17 ions / cm 2

[0063] The test of the cavitation performance is carried out according to the American ASTM standard. The experimental equipment is the ultrasonic vibration cavitation test machine produced by Ningbo Xinzhi Biotechnology Co., Ltd., and the sample to be tested is fixed on the horn of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com