High temperature resistance bonding coating used for surface of nickel base alloy fastener and preparation method thereof

A nickel-based alloy and bonding coating technology, which is applied in metal material coating process, coating, ion implantation plating, etc., can solve the uncertainty of coating thickness uniformity and anti-seizing effect, and increase installation and fastening Problems such as eliminating the parts process and reducing the efficiency of assembly work, to achieve the effect of increasing convenience and reliability, small thickness, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The above-mentioned preparation method for the high-temperature-resistant bonding coating on the surface of nickel-based alloy fasteners comprises the following steps:

[0023] The first step: cleaning the substrate: first degrease, remove dust and remove the insulating layer from the nickel-based fastener substrate, then place the nickel-based fastener substrate in a vacuum chamber to generate plasma, induce ion generation and bombard nickel The surface of the base fastener substrate, the bombardment time is 5-20 minutes.

[0024] The second step: Deposit the intermediate coating: use the vapor deposition method to deposit the intermediate coating on the surface of the nickel-based fastener substrate cleaned in the first step. When the intermediate coating is a Cr layer, pure Cr is used as the target or evaporation source A Cr layer is deposited on the surface of the nickel-based fastener substrate by magnetron sputtering or ion plating, and the thickness of the middle...

Embodiment 1

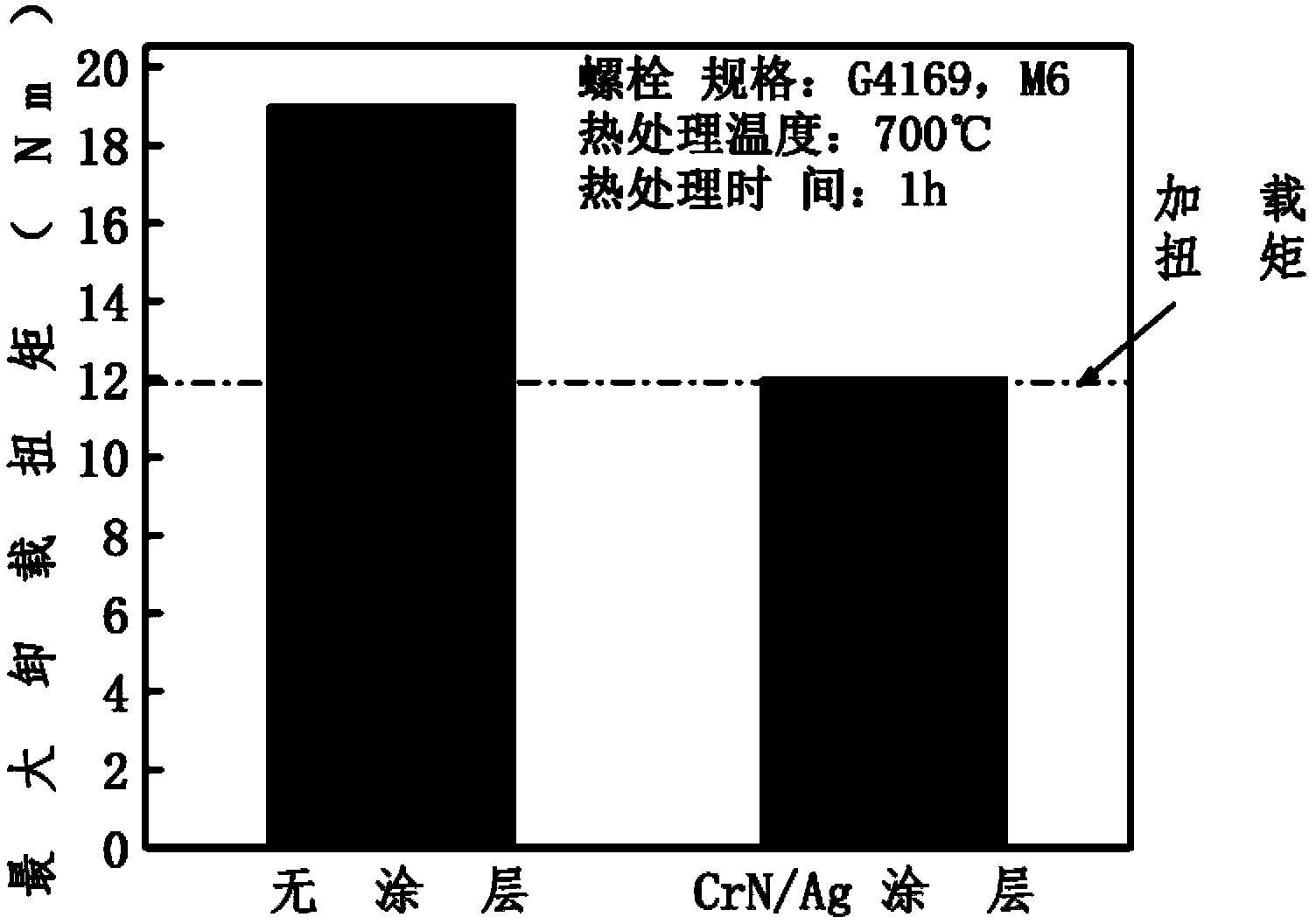

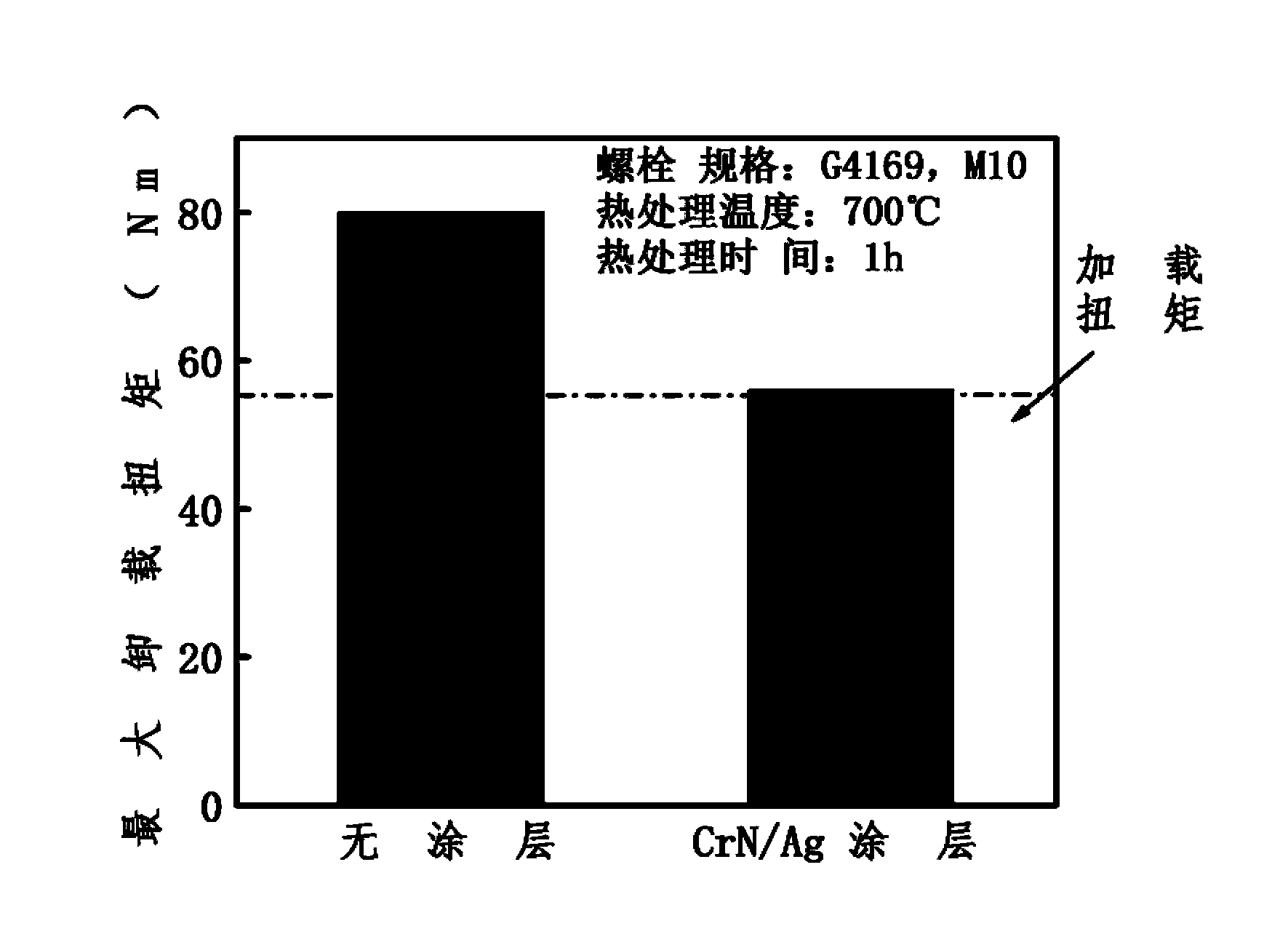

[0031] The base of the nickel-based fastener is an M6 bolt / nut whose material grade is G4169 (bolt / nut means a bolt and a nut). Deposition of high temperature bond resistant coatings on bolt / nut surfaces. The intermediate coating is a Cr layer with a thickness of 0.2um. The surface coating is composed of CrN phase and Ag phase, and the atomic percentage of Ag atoms in the surface coating is 3%.

[0032] Preparation process: first, surface cleaning treatment is performed on the M6 bolt / nut whose material grade is G4169. The cleaning treatment includes conventional degreasing, dust removal and insulation removal. Then the bolt / nut is placed in a vacuum chamber, and Ar gas with a pressure of 1Pa is introduced to make the bolt / nut in a negative bias state of 1000V. The negative bias voltage triggers plasma generation, and the ion bombards the surface of the bolt / nut. The bombardment time is 5-20 minutes; deposit a Cr layer on the surface of the bolt / nut by magnetron sputtering...

Embodiment 2

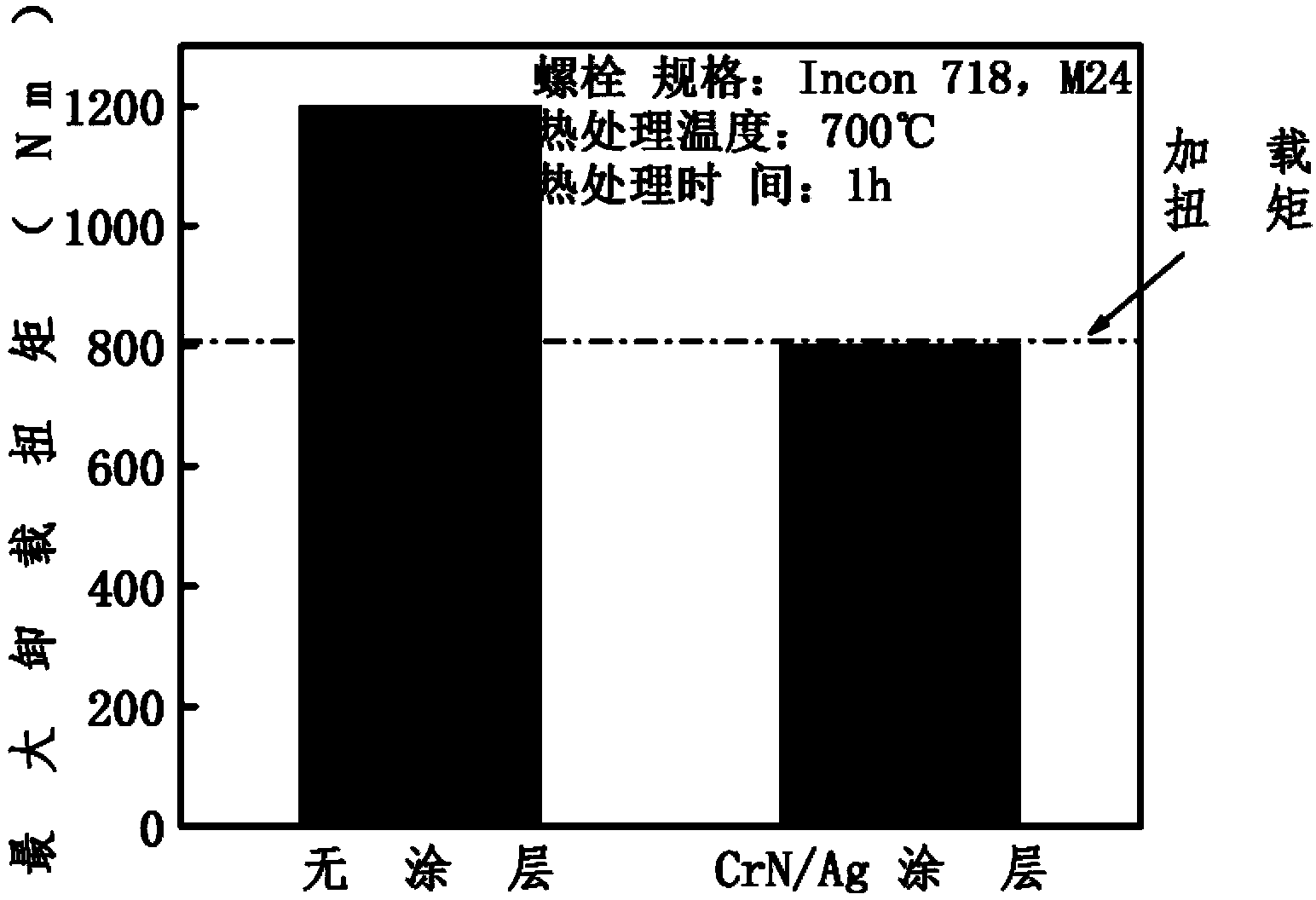

[0034] The base of nickel-based fasteners is M24 bolt / nut whose material grade is Incon718. Deposition of high temperature bond resistant coatings on bolt / nut surfaces. Intermediate coating is Ni 1-x Cr x Concentration gradient layer with a thickness of 0.5um. The surface coating is composed of CrN phase and Ag phase, and the atomic percentage of Ag atoms in the surface coating is 6%.

[0035] Preparation process: First, the surface cleaning treatment is performed on the M24 bolt / nut whose material grade is Incon718. The cleaning treatment includes conventional degreasing, dust removal and insulation removal. Then the bolt / nut is placed in a vacuum chamber, and Ar gas with a pressure of 1Pa is introduced to make the bolt / nut in a negative bias state of 1000V. The negative bias voltage triggers plasma generation, and the ion bombards the surface of the bolt / nut. The bombardment time is 5-20 minutes. Ni was then deposited by double-target sputtering co-deposition 1-x Cr x...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com