Method for improving hardenability of 40MnBH steel for hardenability maintenance structure

A technology for hardenability and structure, which is applied in the field of improving the hardenability of 40MnBH steel for hardenability-retaining structures. It can solve the problems of not considering and specifying the influence of chemical composition and performance, hardenability is difficult to meet market demand, etc., to achieve The heat treatment method is simple, the cost is low, and the effect of comprehensive performance is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

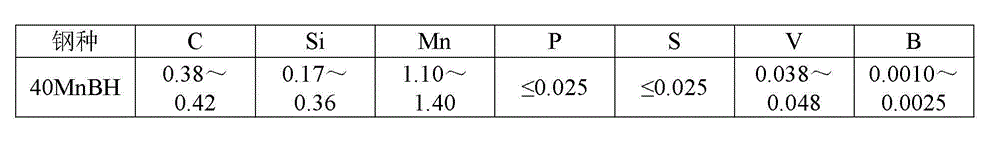

[0009] After special research by scientific and technical personnel and experiments in a 25kg vacuum induction furnace, the composition range of molten steel for industrial production is designed, summarized and optimized as shown in Table 1, and the name of the steel grade is 40MnBH.

[0010] Table 1 Composition requirements of hardenability structural steel 40MnBH, w%

[0011]

[0012] The process flow is: 80t converter smelting→LF furnace refining→VD furnace vacuum degassing→continuous casting (the billet size is 240mm×240mm).

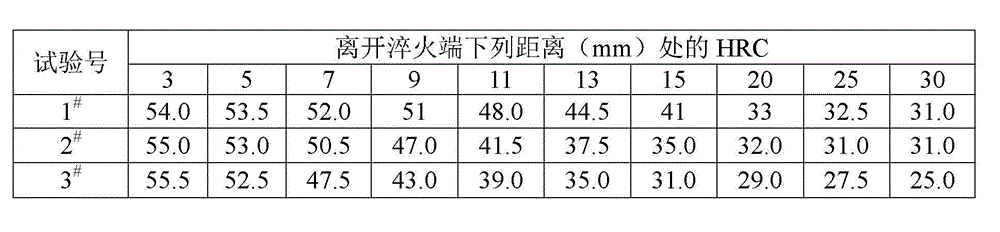

[0013] 3 heats of steel were produced for industrial trial production, and the specific process parameters were controlled as follows:

[0014] 1) Converter production

[0015] The carbon content, phosphorus content and tapping temperature of the molten steel at the end of the converter are shown in Table 2.

[0016] Table 2 The temperature and composition of 40MnBH tapping

[0017] Test No. Tapping temperature, ℃ Tapping carbon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com