Method for decomposing stone coal vanadium ore by aging with sulfuric acid

A technology of stone coal vanadium and sulfuric acid, applied in the direction of improving process efficiency, can solve problems such as inability to carry out large-scale continuous production, difficult control of production process indicators, unstable product quality, etc., to save energy consumption and shorten leaching cycle. , the effect of pure leachate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

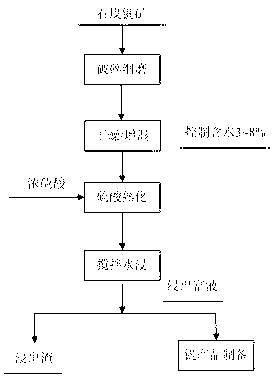

Image

Examples

Embodiment 1

[0033] See attached figure 1 , take 1000g of stone coal vanadium ore from a certain place in Guizhou, finely grind it to 65% below 0.074mm, control the water content to 7%, mix 50g of sodium sulfate, then add 126ml of 98% concentrated sulfuric acid and mix evenly, measure The temperature of the obtained material was raised to 161°C, and then the matured material was placed in a sealed box. After being stored for 24 hours, the matured material was taken out, crushed, and soaked in water at 95°C for 6 hours at a liquid-solid ratio of ml / g 2:1. According to the experiment, the leaching rate of vanadium was 84.37% (based on slag), the leaching rate of iron was 3.12% (based on slag), and the leaching solution contained 3.39g / L vanadium and 0.61g / L iron.

Embodiment 2

[0035] Take 1000g of stone coal vanadium ore from a certain place in Shaanxi, finely grind it to 70% below 0.074mm, control the water content to 5%, mix it with 60g of sodium sulfate, and then add 140ml of 98% concentrated sulfuric acid to mix and mature. The temperature of the obtained material was raised to 168°C, and then the matured material was placed in a sealed box and stored for 36 hours. After taking it out, the matured material was crushed and soaked in water at 90°C for 6 hours at a liquid-solid ratio of ml / g 1.8:1. According to the experiment, the leaching rate of vanadium is 80.06% (based on slag), and the leaching rate of iron is 3.88% (based on slag). The leach solution contains 4.23g / L vanadium and 0.44g / L iron.

Embodiment 3

[0037] Take 1000g of stone coal vanadium ore from a certain place in Shiyan, Hubei, finely grind it to 70% below 0.074mm, control the water content of the material to 5%, mix it with 60g of sodium sulfate, and then add 82ml of 98% concentrated sulfuric acid and mix evenly. It was measured that the temperature of the material was raised to 155°C, and then the material was placed in a sealed box. After aging for 48 hours, the cooked material was taken out, crushed, and soaked in water at 95°C for 6 hours at a liquid-solid ratio of ml / g 2:1. According to the experiment, the leaching rate of vanadium was 84.12% (based on slag), the leaching rate of iron was 2.57% (based on slag), and the leaching solution contained 3.12g / L vanadium and 0.65g / L iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com