Separation and purification device and separation and purification method for butanol and acetone

A technology for purifying butanol and acetone is applied in the biological field to achieve the effects of increasing equipment investment, saving purification energy consumption, and improving production, separation and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

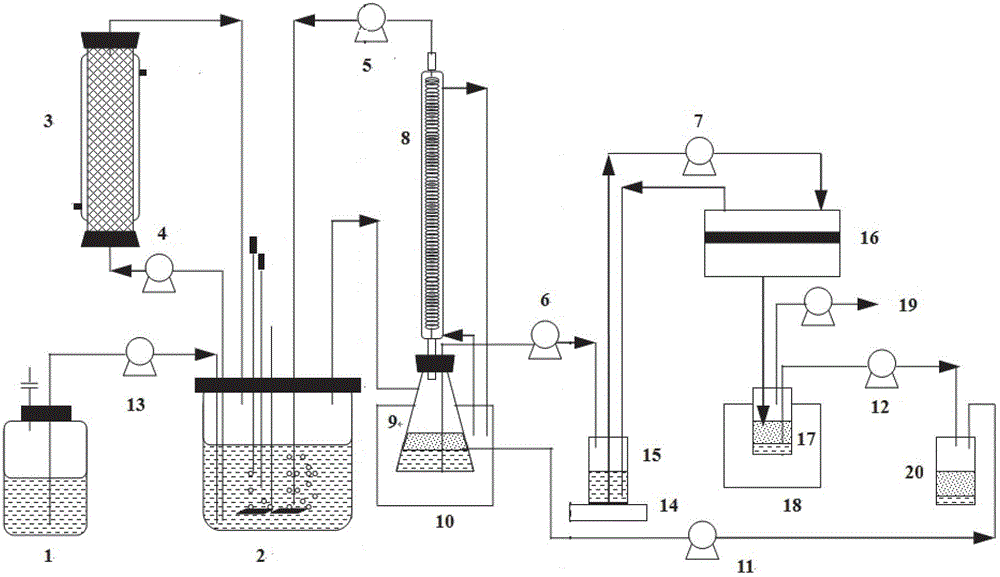

Method used

Image

Examples

preparation example Construction

[0051] Preparation of pervaporation membrane: Polydimethylsiloxane (PDMS) was purchased from Dow Corning, USA. Zeolite nanomaterials (ZSM-5) were purchased from Zeolyst International, USA. ZSM-5 was first dried at 80°C for 24 hours. The gel-forming agent base liquid and curing agent in polydimethylsiloxane (PDMS) are mixed at a ratio of 10:1. For the preparation of a single PDMS polymer membrane, centrifuge directly at 8,000 rpm for 5 min for subsequent operations. For the PDMS mixed membrane with ZSM-5 material added, the ZSM-5 of the specified weight ratio (20% and 80% were selected respectively in Examples 2 and 3 of the present invention) was mixed with the PDMS membrane after the mass ratio of 10:1 The solution was mixed and centrifuged at 8000 rpm for 5 minutes for subsequent operations. The follow-up operation is to ultrasonically treat the film-forming solution for 15 minutes or vacuumize to remove the air bubbles in the film-forming solution, then use a scraper to ...

Embodiment 1

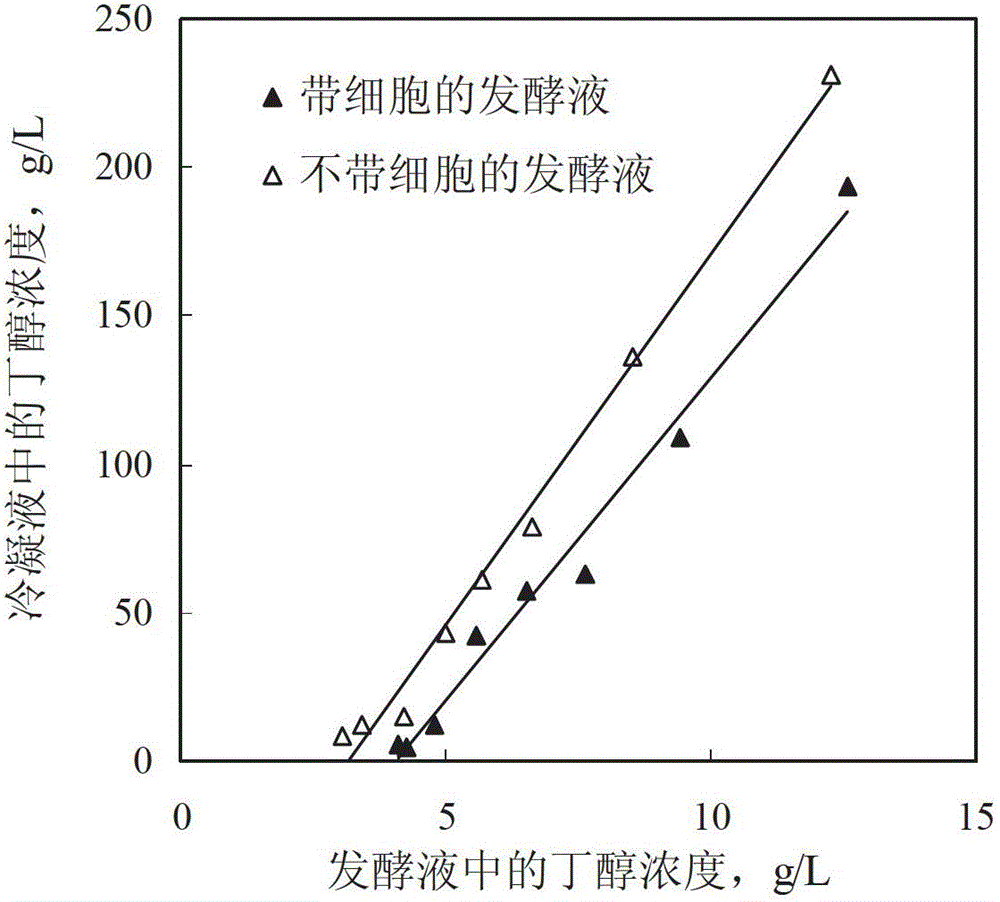

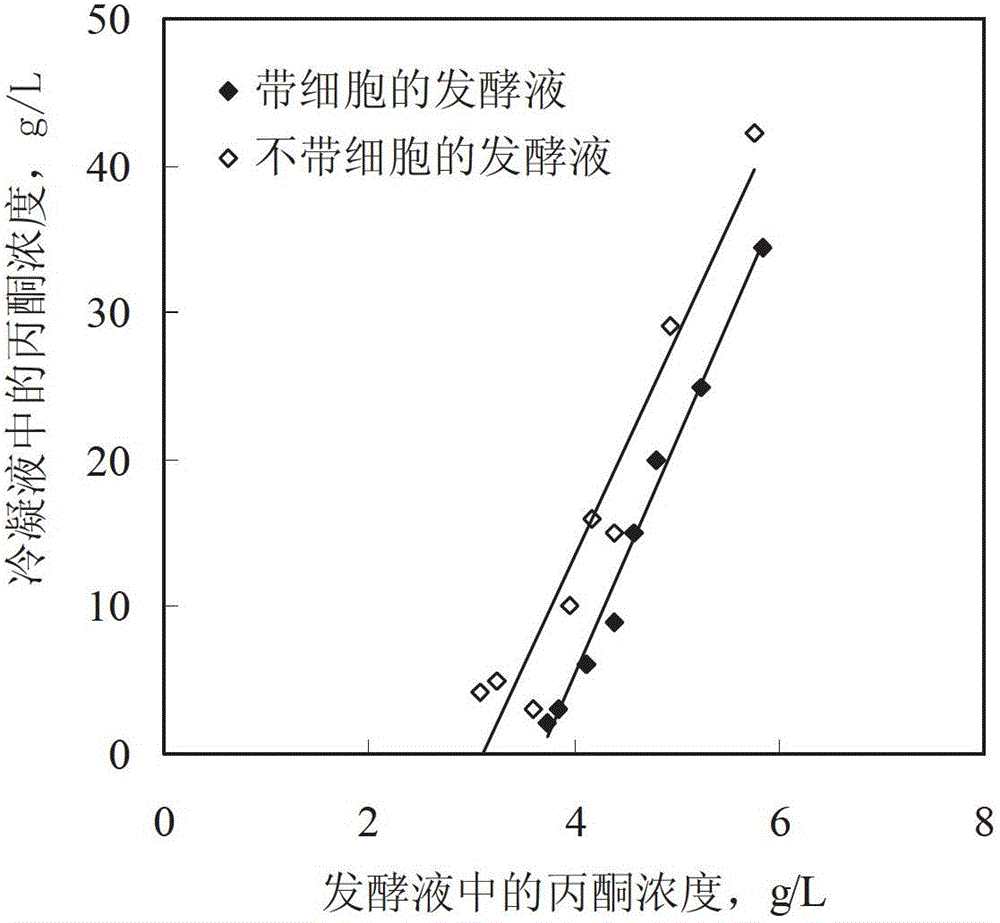

[0062] Example 1: Separation and purification using gas stripping-pervaporation coupling purification method of PDMS polymer membrane

[0063] The cultivation and fermentation of the acetone-butanol-producing bacteria were carried out as described above. When fermentation starts in the stirred bioreactor 2, start the pump 4 to start the cell immobilization system until the end of the fermentation, and at the same time start the low-temperature cooling constant temperature tank 10 to provide the low-temperature condensate for the stripping condenser pipe 8. The self-produced gas produced by the production bacteria during the fermentation process forms bubbles through the fermentation system and enters the stirred bioreactor 2 as stripping gas. The butanol and acetone vapors that are stripped out are condensed after passing through the condenser pipe 8, and the condensate containing butanol and acetone is left to stratify in the condensate storage tank 9, and the upper layer is ...

Embodiment 2

[0069] Example 2: Separation and purification using PDMS / 20%ZSM-5 mixed membrane gas stripping-pervaporation coupled purification method

[0070] Carry out the cultivation and fermentation of acetone butanol producing bacteria by the method among the example 1. For the separation and purification process of air stripping-pervaporation coupling purification method, the pervaporation membrane used is a mixed matrix membrane, which is composed of 20% ZSM-5 nano-zeolite material and polydimethylsiloxane mixed and then cross-linked to form membrane. Nano zeolite is hydrophobic, which can increase the selectivity of the membrane to butanol and increase the concentration of butanol in the membrane permeate. The scanning electron micrograph of the mixed film of PDMS / 20%ZSM-5 is as follows Figure 5 .

[0071] Other than that, other methods are the same as in Example 1, and the parameters of the gas stripping-pervaporation coupling purification device are also the same as in Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com