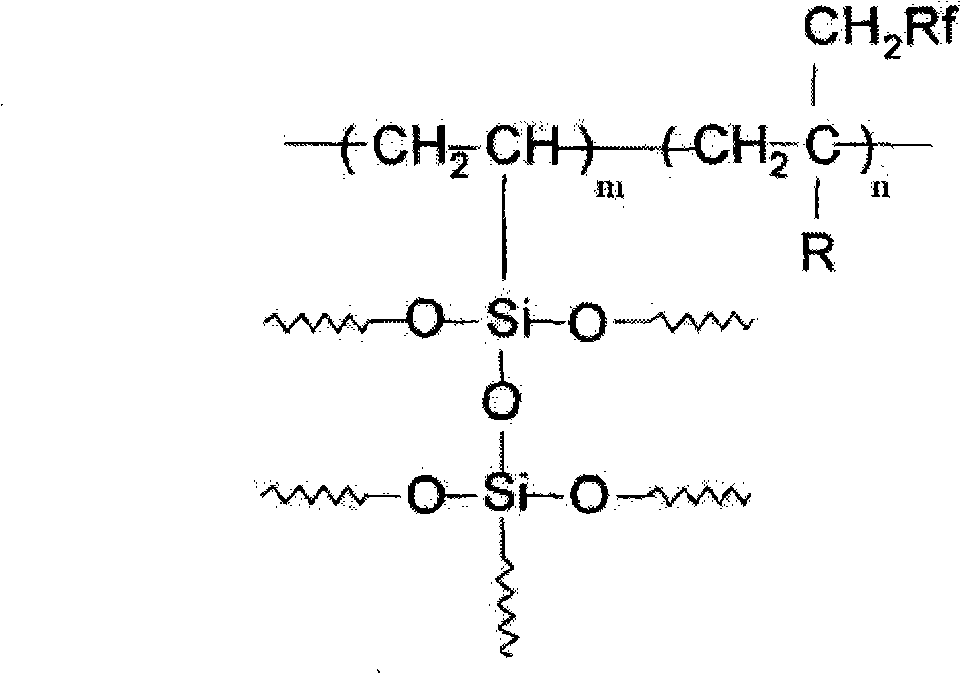

Anti-fouling wear-resisting transparent fluorine-silicone polymer material and preparation method thereof

A polymer material, transparent technology, applied in antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve problems such as corrosion, low product performance, pollution of equipment, etc., to avoid environmental pollution and improve product quality. performance, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of anti-fouling and wear-resistant transparent fluorosilicone polymer material

[0034] Add 10 grams of 1-iodoperfluorooctane, 20 grams of vinyl triisopropoxy silane, 100 grams of methanol, 0.05 grams of initiator ammonium persulfate, and fungicide tetradecyl dimethyl into the high pressure reactor. Benzyl ammonium chloride 0.001 grams, additives nano titanium dioxide powder 0.005 grams. Seal the autoclave and fill it with nitrogen until the pressure reaches 2 atmospheres. Start heating. When heated to 90°C, constant-temperature polymerization starts at a stirring speed of 500 revolutions per minute. After 12 hours, the polymerization reaction is stopped and quickly cooled to room temperature. The target product can be obtained by removing the solvent from the product.

Embodiment 2

[0035] Example 2 Preparation of anti-fouling and wear-resistant transparent fluorosilicone polymer material

[0036] Add 20 grams of perfluorooctyl ethylene, 30 grams of vinyl tri-tert-butoxy silane, 100 grams of ethanol, 0.4 grams of initiator potassium persulfate, and 0.02 grams of bactericide pentachloronitrobenzene into the autoclave. 0.1 g of nanometer titanium dioxide powder. Seal the autoclave and fill it with nitrogen until the pressure reaches 5 atmospheres. Start heating. When heated to 120°C, constant temperature polymerization starts at a stirring speed of 900 revolutions per minute. After 12 hours, the polymerization reaction is stopped and quickly cooled to room temperature. The target product can be obtained by removing the solvent from the product.

Embodiment 3

[0037] Example 3 Preparation of anti-fouling and wear-resistant transparent fluorosilicone polymer material

[0038] Add 15 grams of allyl perfluoroether, 25 grams of vinyl trimethoxysilane, 100 grams of propanol, 0.2 grams of initiator sodium persulfate, and 0.01 grams of bactericide tetrachloroisophthalonitrile into the autoclave. Additives: 0.05 grams of nano titanium dioxide powder. Seal the autoclave and fill it with nitrogen until the pressure reaches 3 atmospheres. Start heating. When heated to 100°C, constant-temperature polymerization starts at 700 revolutions per minute. The polymerization reaction is stopped after 12 hours and quickly cooled to room temperature. The target product can be obtained by removing the solvent from the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com