Pulse backflush deashing device for filter

A technology of pulse backflushing and ash cleaning device, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc. Nozzle shaking and other problems, to overcome the eccentricity and vibration of the airflow, improve the airflow distribution, and overcome the effects of non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

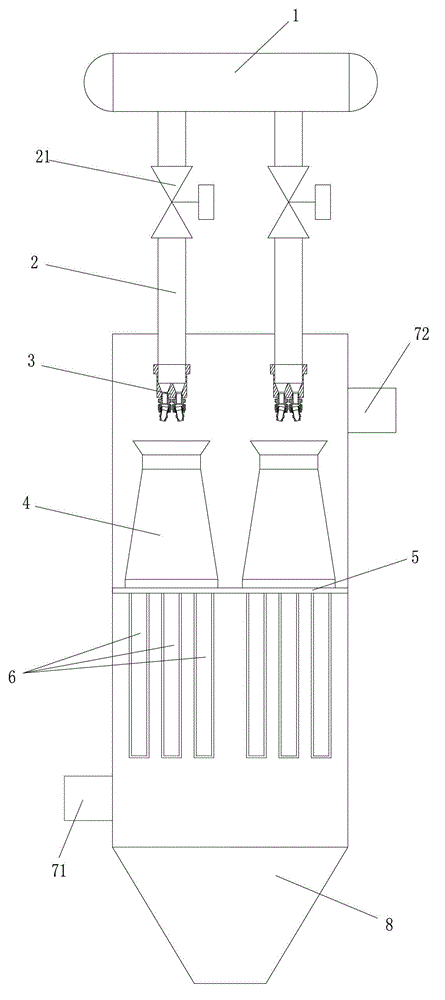

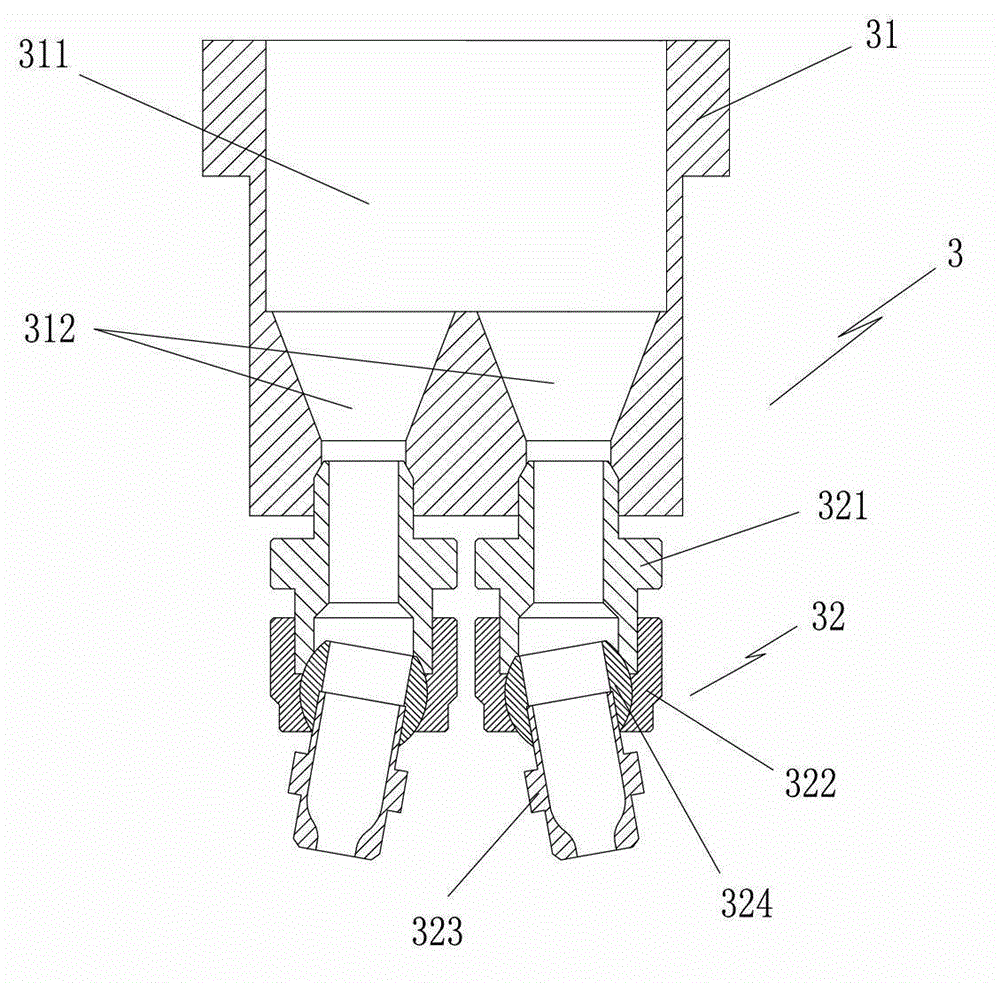

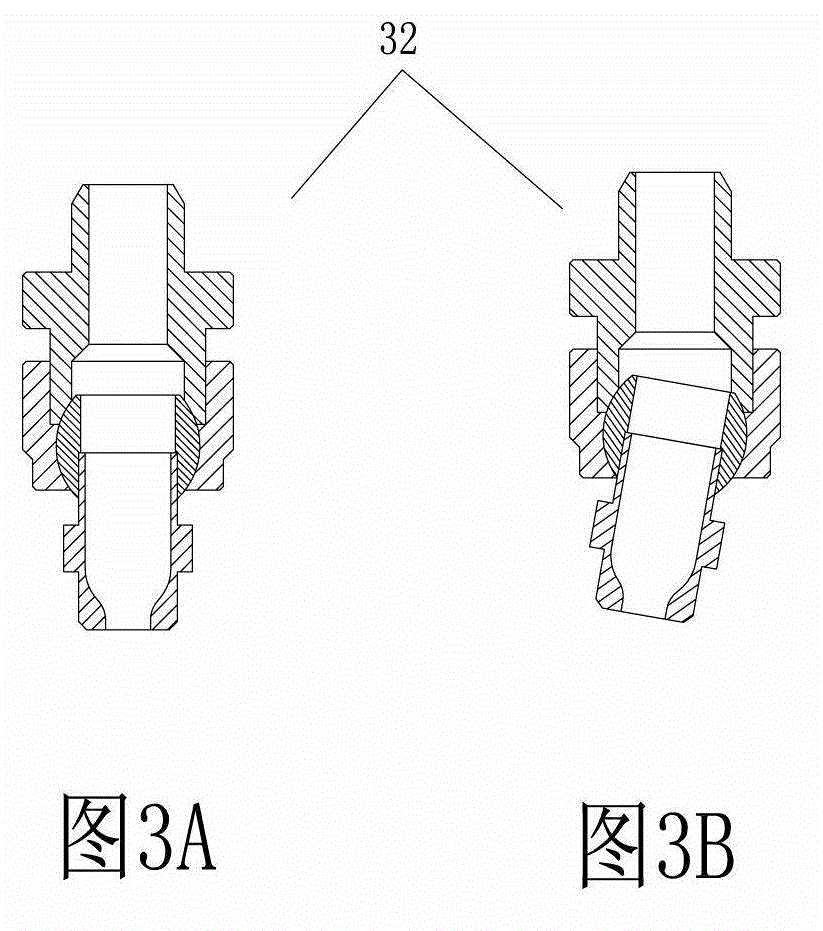

[0041] The present invention proposes a pulse back-blowing dust-cleaning device for a filter, such as figure 1 , figure 2 As shown, the tube plate 5 of the filter is provided with a filter unit. In this embodiment, the tube plate is provided with multiple sets of filter units, and each set of filter units is provided with a plurality of filter tubes 6; the filter The tube sheet 5 seals and divides the filter into an upper clean gas chamber and a lower dust-laden gas chamber, and the dust-laden gas enters the dust-laden gas chamber of the filter through the gas inlet 71 of the filter, and the particles in the air flow are intercepted On the outer surface of the filter tube 6, a powder cake layer is formed. After the gas is filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com