Printed circuit board having single reflective structure and led packaging manufacturing method utilizing the same

A technology for printed circuit boards and light-emitting diodes, applied in printed circuit manufacturing, printed circuit secondary processing, printed circuits, etc., to achieve the effects of preventing reabsorption, increasing optical power, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, preferred embodiments of the printed circuit board with a single reflective structure and the method for manufacturing an LED package using the printed circuit board according to the present invention will be described in detail.

[0053] The characteristics and advantages of the printed circuit board with a single reflective structure and the method for manufacturing a light emitting diode using the printed circuit board according to the present invention will be more clearly understood through the detailed description of the following embodiments.

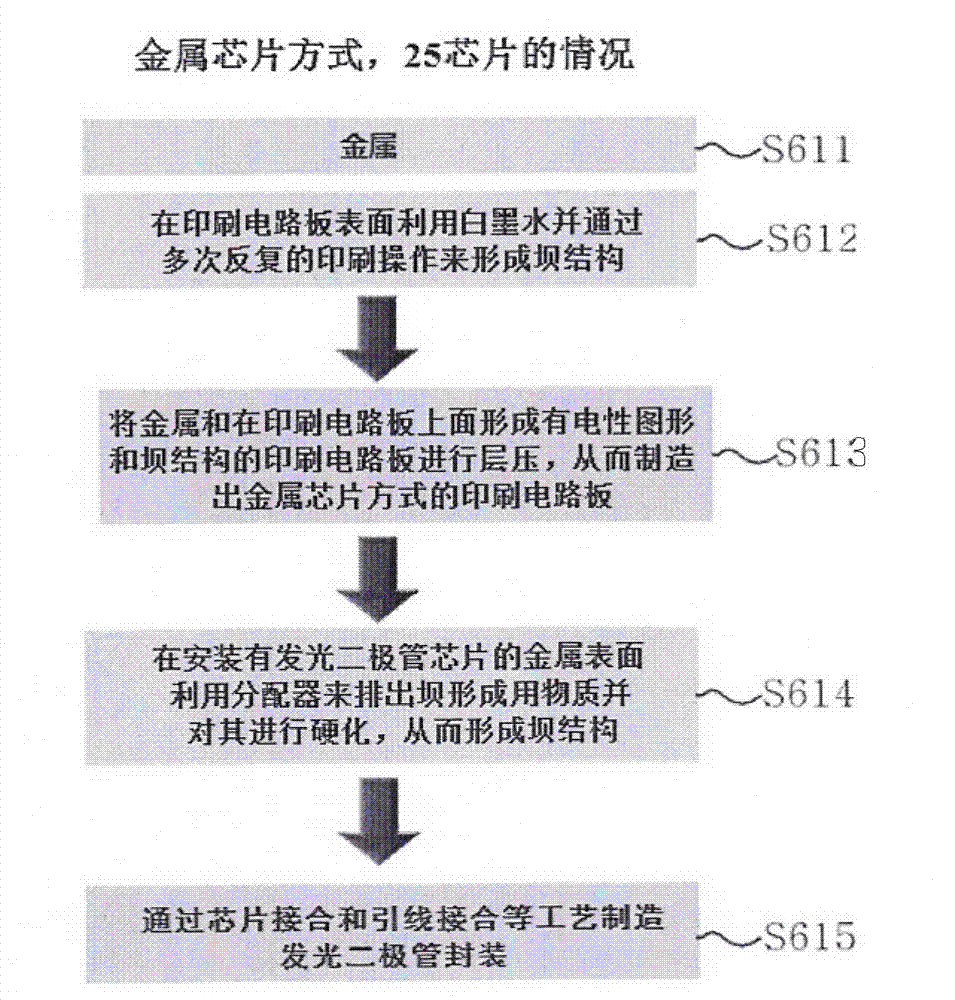

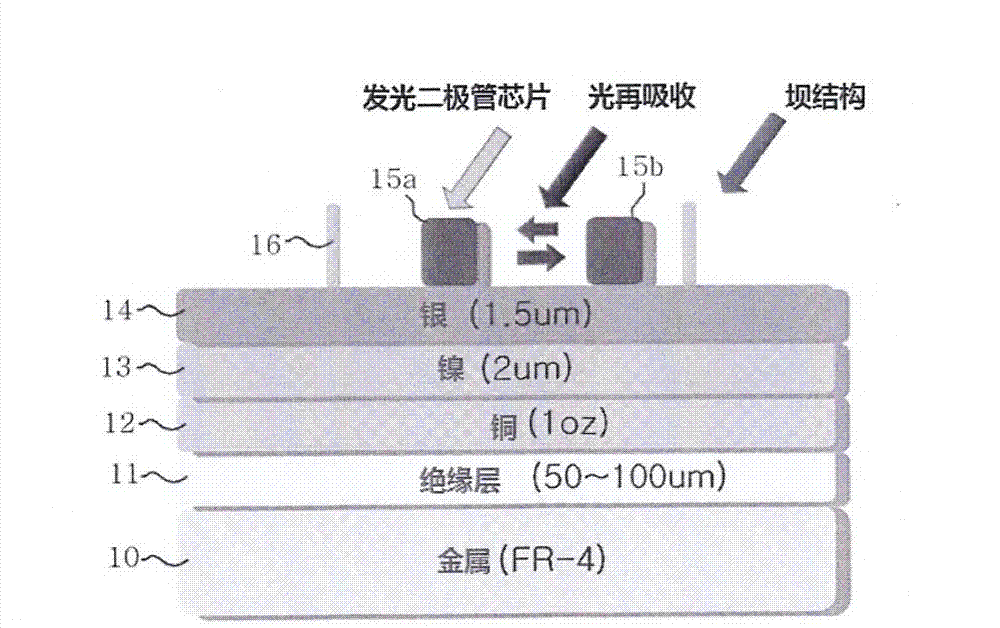

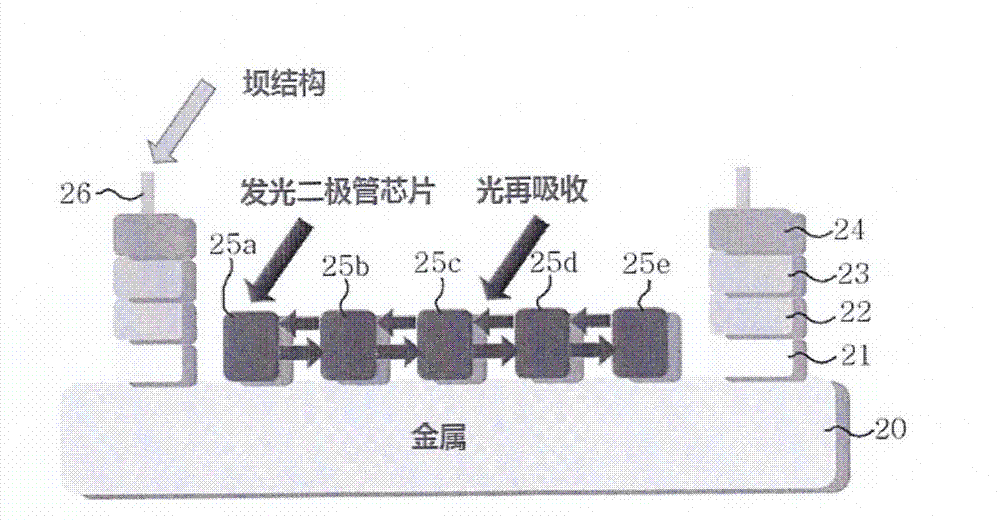

[0054] image 3 It is a composition diagram of a chip on board (Chip On Board) and a heat sink chip (Chip On Heat-sink) light emitting diode package according to an embodiment of the present invention, Figure 4 It is a configuration diagram of a chip-on-metal (Chip On Metal) light emitting diode package according to another embodiment of the present invention.

[0055] In the case of using more than one chip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com