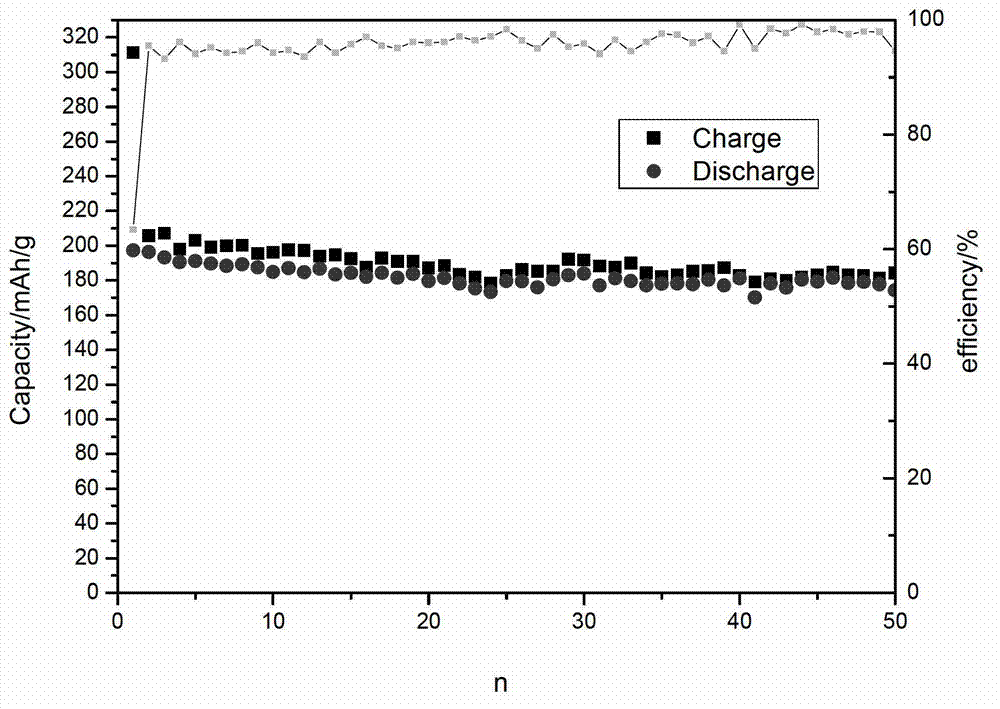

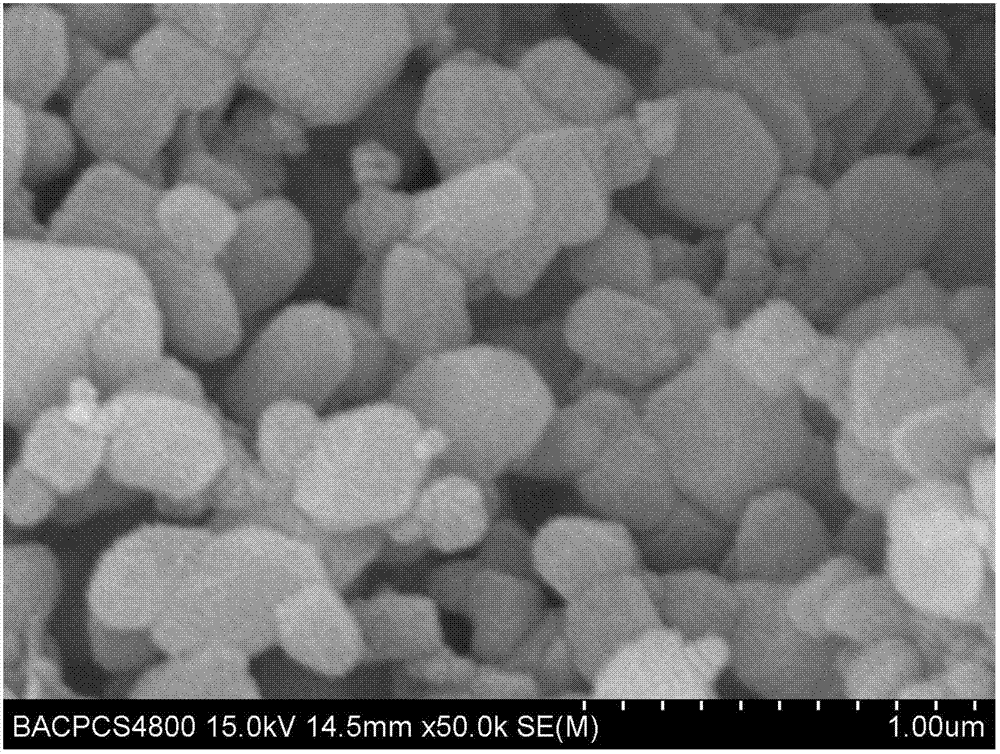

Method of preparing manganese-based multi-component oxide cathode materials of lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as difficulty in meeting the needs of high-capacity, high-energy-density electronic products, harsh synthesis conditions, and poor ionic conductivity. Good commercial application prospects, good morphology and structure, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A method for preparing a manganese-based multi-component oxide positive electrode material for a lithium ion battery, the specific preparation steps are as follows:

[0028] 1) 3.081g LiNO 3 and 3.99g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 7 mL of water;

[0029] 2) Add 3.9mL of 50wt% Mn(NO 3 ) 2 The solution is uniformly mixed with the solution prepared in step 1);

[0030] 3) Add 2.2mol citric acid into the solution prepared in step 2), stir evenly until the solution is completely dissolved, and let it stand for about 12 hours;

[0031] 4) Weigh 1g of carbon felt, measure 15mL of the solution prepared in step 3) and drop it evenly on the carbon felt, let it stand for 2 hours to make the carbon felt fully absorb the solution;

[0032] 5) Put the mixture prepared in step 4) into a drying oven at 80°C, take it out after 6 hours, and obtain the precursor;

[0033] 6) Put the precursor prepared in step 5) into a tube furnace, heat up to 300°C at a rate of 5°C / min and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com