Hardware modularization and software configurable industrial control instrument device and method

A hardware module and software technology, applied in the direction of comprehensive factory control, comprehensive factory control, sustainable manufacturing/processing, etc., can solve problems such as unfavorable unified management of industrial production, inconvenient factory replacement, etc., to facilitate unified management and replacement, The effect of good flexibility and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

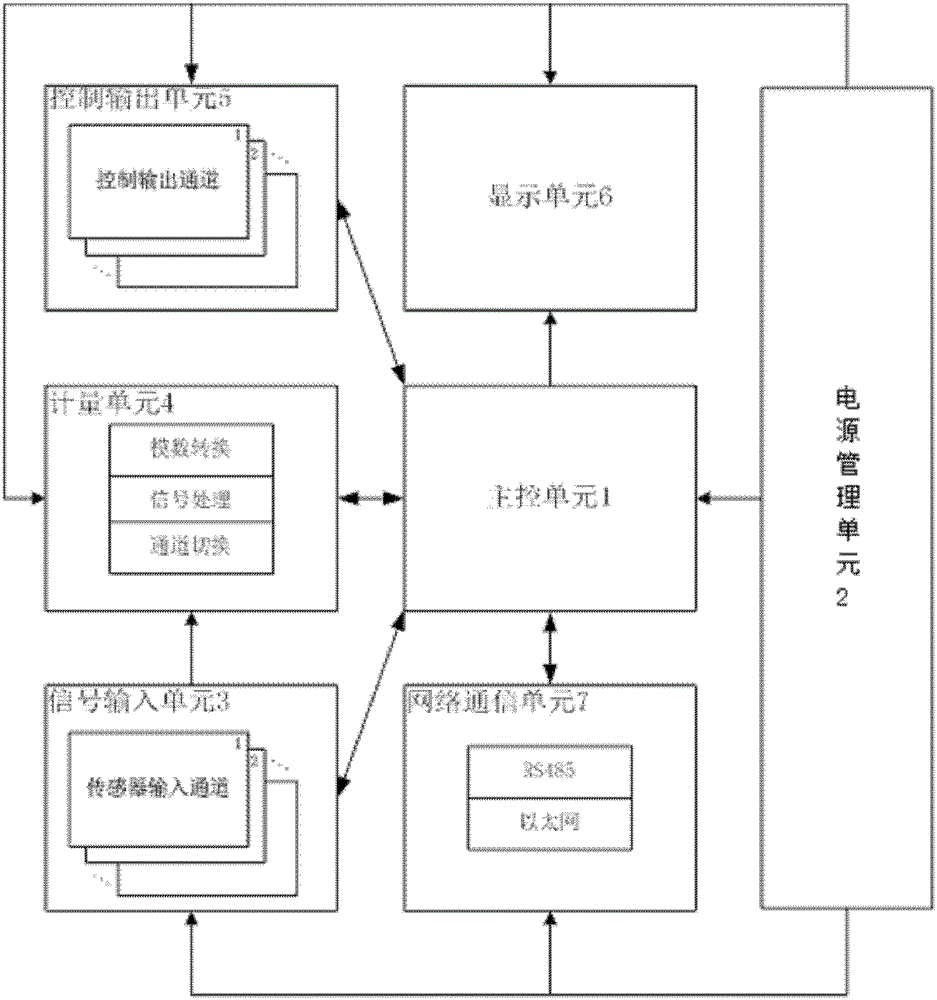

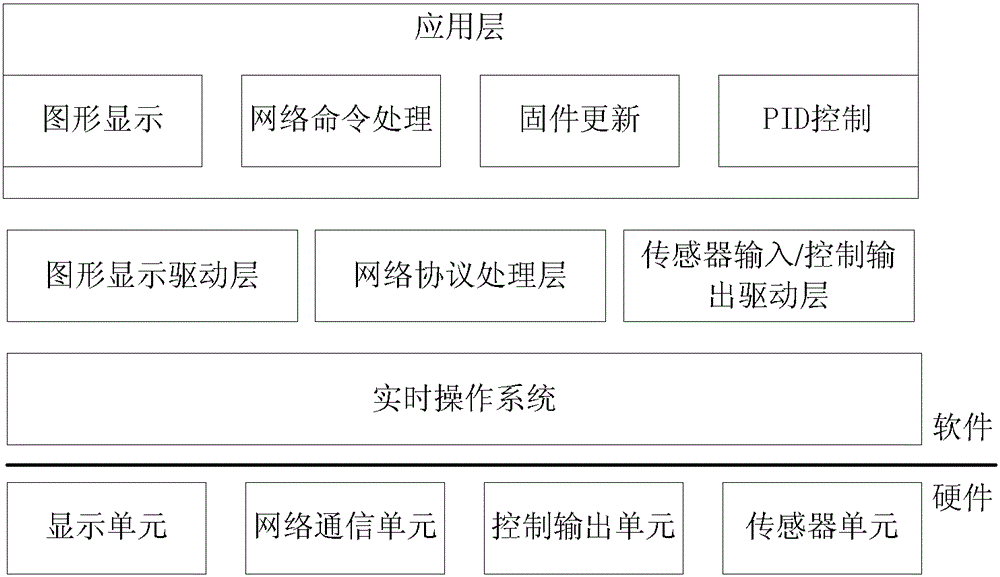

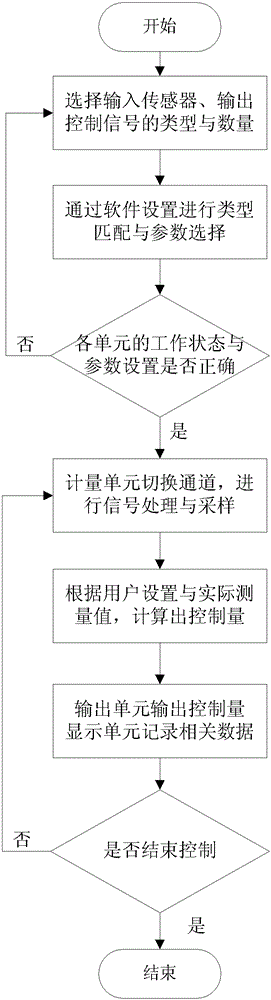

[0031] Such as figure 1 As shown, the device includes: a main control unit 1, a power management unit 2, a signal input unit 3, a metering unit 4, a signal output unit 5, a display unit 6 and a network communication unit 7, wherein: the main control unit 1 is the control unit of the whole device The control core is responsible for the control and deployment of other units. The power management unit 2 rectifies, filters, and transforms the externally provided commercial power to provide a stabilized voltage output for each unit circuit of the device. The signal input unit 3 receives multi-channel sensor input signals from the outside, and outputs them to the metering unit 4 after channel switching, and the metering unit 4 transmits the measured value to the main control unit 1 after processing the signals such as filtering, amplification, and sampling. The control unit 1 calculates the control result according to the measured value and the parameters set by the user, and outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com