Electroplated diamond wire saw sand-applying device

A technology for electroplating diamond and equipment, applied in electrolytic coatings, coatings, etc., can solve the problems of slow plating solution circulation, low current density, large space occupation, etc., to eliminate core wire asynchrony, high current density, and improve holding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

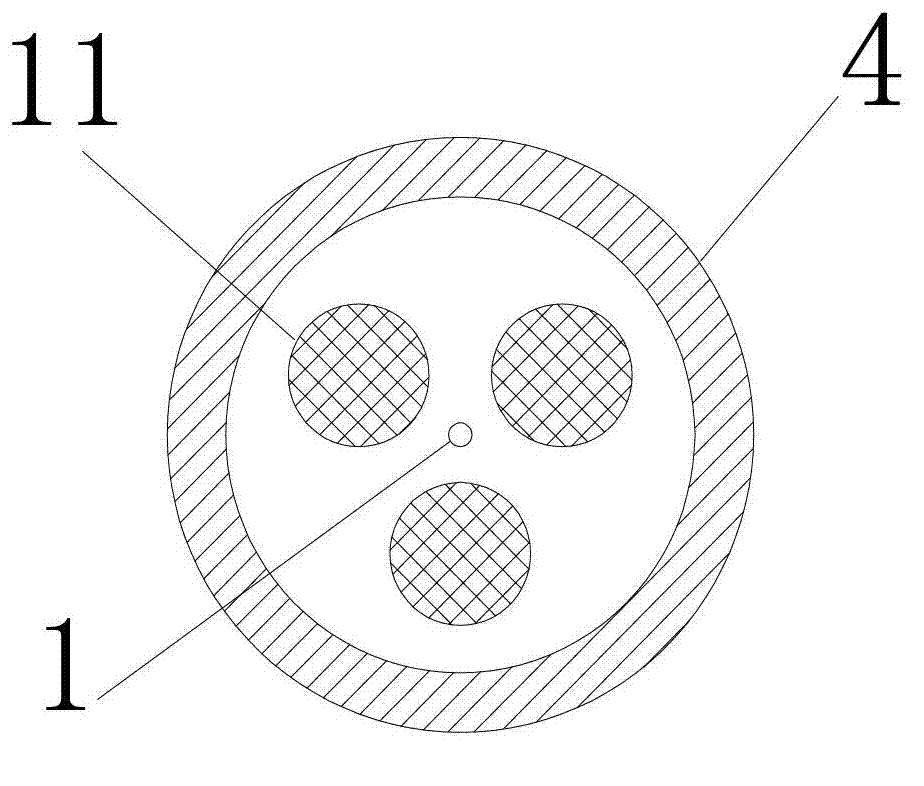

[0050] Such as figure 1 As shown, the present invention is an electroplating diamond wire saw sanding equipment, which is characterized in that the equipment is provided with a vertical tube type upper sand tank 4, a liquid return box 7, a plating solution mother tank 9, and a liquid return box 7 from top to bottom. The guide wheel 3 is fixed inside, and the core wire 1 is wound successively around the incoming conductive wheel 2-1 and the guide wheel 3 at the bottom of the vertical tube type upper sand tank 4, and then passed through the vertical tube type upper sand tank 4, and finally wound and set on the vertical tube type upper sand tank On the outgoing line conductive wheel 2-2 at the top of the slot 4, the incoming line conductive wheel 2-1 and the outgoing line conductive wheel 2-2 are connected in parallel to the negative pole of the electroplating power supply 12, and the core wire 1 in the vertical tube type upper sand tank 4 A metal anode 11 is arranged around, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com