High elastic corrosion resistant epoxy sealant and preparation method thereof

An epoxy sealing and corrosion-resistant technology, used in epoxy resin glue, chemical instruments and methods, adhesives, etc., can solve problems such as poor sealing performance, unsatisfactory effect, and easy cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

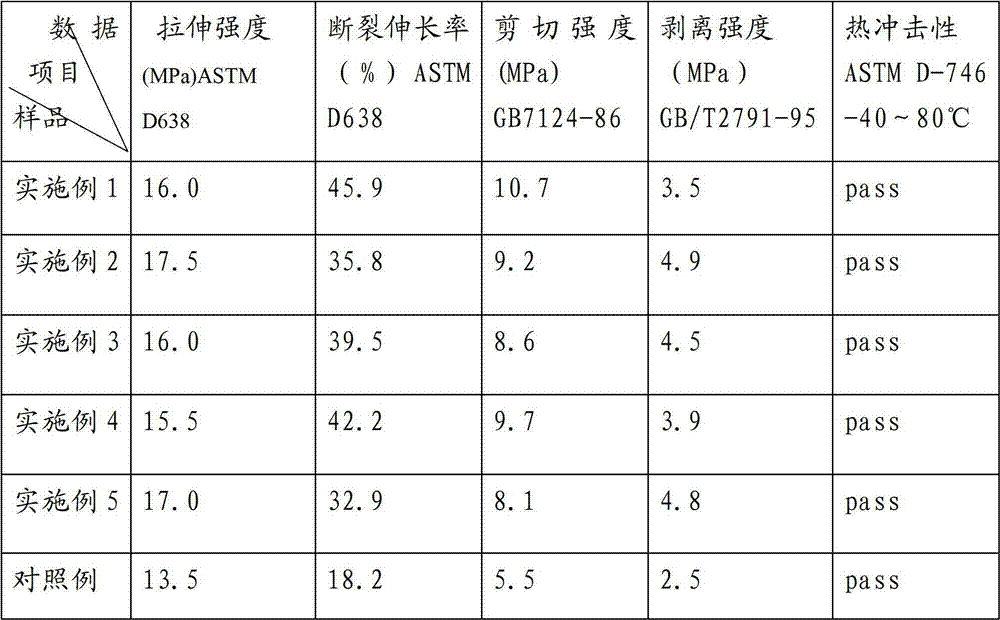

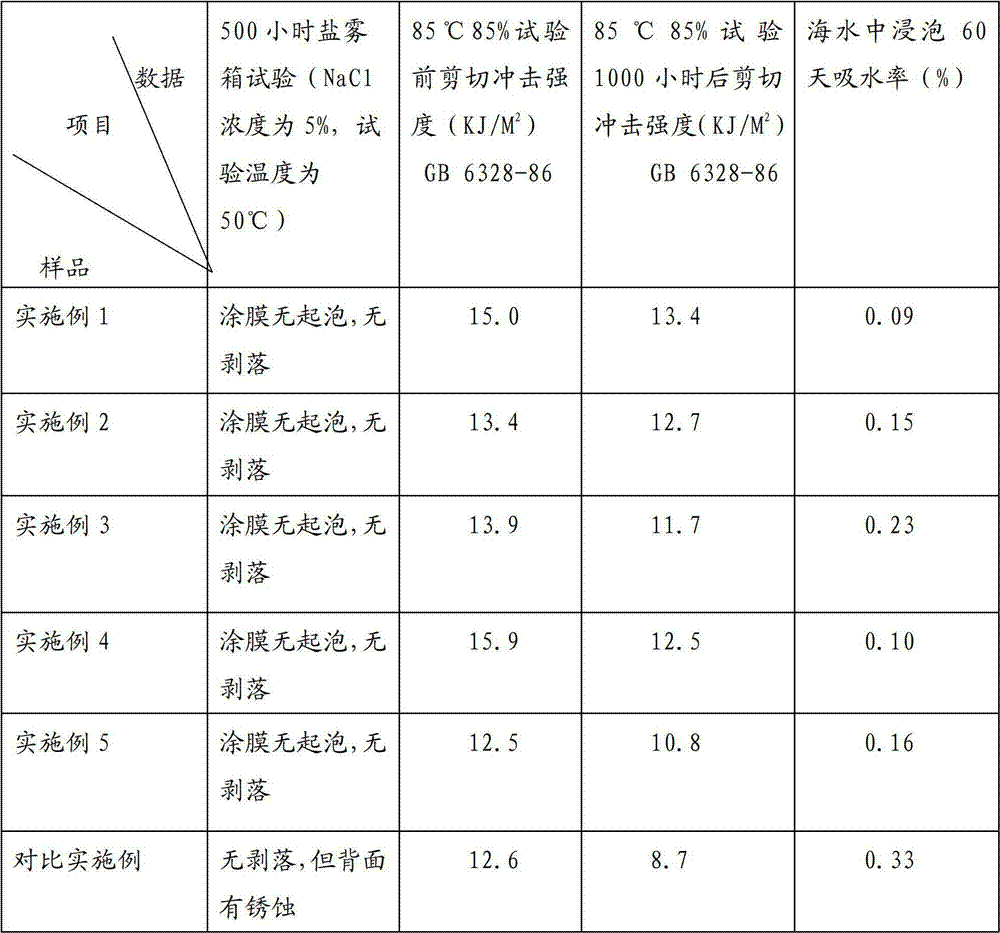

Examples

Embodiment 1

[0052] 1) Preparation of component A:

[0053] The preparation of the A component is: 20 parts by weight of modified epoxy resin elastomer HyPox RA840, 15 parts of epoxy resin EPON862, 15 parts of hyperbranched epoxy resin, 8 parts of xylene formaldehyde resin, Add 12 parts of polypropylene glycol diglycidyl ether, 0.3 parts of coupling agent KH-560, and 0.3 parts of wetting and dispersing agent Texaphor P63 into the double planetary power mixer, and the rotation speed is 500 rpm, and the revolution speed is 15 rpm Under the condition of rotation speed of 800 rpm and revolution speed of 20 rpm, mechanically stir for 0.5 hours; then add 18 parts of quartz powder; then add 10 parts of fumed silica Stir for 20 minutes at a rotation speed of 200 rpm and a revolution speed of 10 rpm, vacuumize to -0.08Mpa until the foam disappears, and obtain component A, which is packaged and placed for use;

[0054] 2) Preparation of component B:

[0055] The preparation of the B component is a...

Embodiment 2

[0058] 1) Preparation of component A:

[0059] The preparation of the A component is as follows: 35 parts by weight of modified epoxy resin elastomer HyPox DA323, 20 parts of epoxy resin NPEF170, 10 parts of hyperbranched epoxy resin, 6 parts of liquid petroleum resin, 1 , Add 10 parts of 4-butanediol diglycidyl ether, 0.2 parts of coupling agent KH-560, and 0.3 parts of wetting and dispersing agent Texaphor P64 into the double planetary power mixing mixer, and at the rotation speed of 400 rpm, revolution Under the condition that the speed is 10 rpm, stir mechanically for 0.5 hours; then add 4 parts of quartz powder and 10 parts of mica powder, and then mechanically stir for 2.5 hours under the conditions of rotation speed of 600 rpm and revolution speed of 15 rpm Add 5 parts of fumed silicon dioxide and stir for 20 minutes under the conditions of rotation speed of 100 rpm and revolution speed of 5 rpm, vacuumize to -0.08Mpa until the foam disappears, and obtain component A. ...

Embodiment 3

[0064] 1) Preparation of component A:

[0065] The preparation of the A component is: 45 parts by weight of modified epoxy resin elastomer NPER-133L, 25 parts of epoxy resin EPON862, 5 parts of hyperbranched epoxy resin, and 2 parts of xylene formaldehyde resin , 5 parts of polypropylene glycol diglycidyl ether, 0.1 part of coupling agent KH-560, and 0.2 part of wetting and dispersing agent Texaphor P64 were added to the double planetary power mixer, and the rotation speed was 700 rpm, and the revolution speed was 20 Under the condition of rotation / minute, mechanically stir for 0.5 hours; then add 15 parts of talcum powder, and then add 15 parts of talcum powder under the conditions of rotation speed of 900 rotation / minute and revolution speed of 25 rotation / minute, mechanically stir for 2.5 hours; then add fumed silica 3 Parts were stirred for 20 minutes under the conditions of rotation speed of 400 rpm and revolution speed of 15 rpm, vacuumed to -0.08Mpa until the foam disap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com