A kind of non-r-mouth double-bevel agricultural polyvinyl chloride nine-meter pipe and its preparation process

A technology for the preparation of polyvinyl chloride, applied to pipes, rigid pipes, mechanical equipment, etc., can solve the problems of wasting financial resources, affecting traffic safety, wasting manpower, etc., and achieve the effects of reducing production costs, good quality, and ensuring overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A nine-meter-long agricultural polyvinyl chloride pipe with double-beveled angles without R mouth, with a diameter of 160mm, adopts the following preparation process:

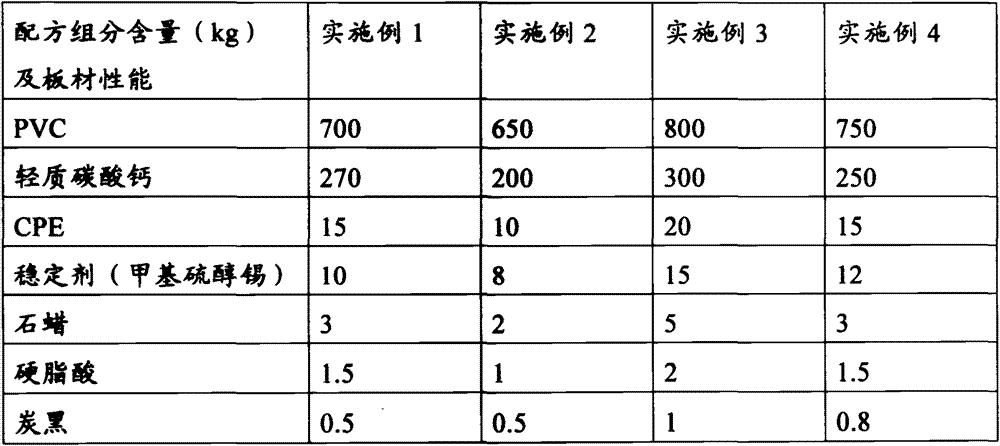

[0045] 1. Accurately weigh the components of the raw material formula indicated in Table 1 for later use.

[0046] 2. Put the weighed light calcium carbonate, paraffin, stearic acid, and carbon black into the high mixing pot of the automatic mixer and mix them. When the temperature of the materials reaches 100°C, add the weighed PVC, Stabilizer and CPE are added into the high mixing pot and further mixed. When the temperature of the material in the high mixing pot reaches 125°C, it will automatically enter the low speed mixer and quickly cool down to below 60°C.

[0047] 3. The dry blend mixed by the automatic mixer enters the 80-156 twin-screw automatic extruder through the automatic feeder for plasticizing and extruding. The automatic feeding machine adopts a spring-type powder feeding machine, which ...

Embodiment 2

[0058] A nine-meter agricultural polyvinyl chloride pipe with double bevel angle without R mouth, with a diameter of 125mm, adopts the following preparation process:

[0059] 1. Accurately weigh the components of the raw material formula indicated in Table 1 for later use.

[0060] 2. Put the weighed light calcium carbonate, paraffin, stearic acid, and carbon black into the high mixing pot of the automatic mixer and mix them. When the temperature of the materials reaches 100°C, add the weighed PVC, Stabilizer and CPE are added into the high mixing pot and further mixed. When the temperature of the material in the high mixing pot reaches 125°C, it will automatically enter the low speed mixer and quickly cool down to below 60°C.

[0061] 3. The dry blend mixed by the automatic mixer enters the 80-156 twin-screw automatic extruder through the automatic feeder for plasticizing and extruding. The automatic feeding machine adopts a spring-type powder feeding machine, which can automa...

Embodiment 3

[0072] A nine-meter-long agricultural polyvinyl chloride pipe with double-beveled angles without R mouth, with a diameter of 90mm, adopts the following preparation process:

[0073] 1. Accurately weigh the components of the raw material formula indicated in Table 1 for later use.

[0074] 2. Put the weighed light calcium carbonate, paraffin, stearic acid, and carbon black into the high mixing pot of the automatic mixer and mix them. When the temperature of the materials reaches 100°C, add the weighed PVC, Stabilizer and CPE are added into the high mixing pot and further mixed. When the temperature of the material in the high mixing pot reaches 125°C, it will automatically enter the low speed mixer and quickly cool down to below 60°C.

[0075] 3. The dry blend mixed by the automatic mixer enters the 80-156 twin-screw automatic extruder through the automatic feeder for plasticizing and extruding. The automatic feeding machine adopts a spring-type powder feeding machine, which c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com